Clariant Confirms Accuracy of its new ONE WAY Sustainability Calculation System

Singapore, July 4, 2013 – The effectiveness of Clariant’s new ONE WAY sustainability calculation system has been confirmed in physical tests carried out by leading machine builder Fong’s.

The test results verified the accuracy of the calculations and measurements obtained from Clariant’s ONE WAY Calculator, a sophisticated software tool that helps textile brands, retailers and manufacturers assess the cost, performance and environmental profile of evaluated products almost instantly.

Unique sustainability service designed to support the textile industry’s efforts Clariant, a world leader in specialty chemicals, developed its ONE WAY sustainability service to provide textile brands, retailers and manufacturers with a fast and reliable method of selecting the most appropriate chemicals and process routes for their requirements. The close consideration of key parameters, including raw materials and water and energy consumption, aims at achieving both economic and ecological benefits.

The database of Clariant’s ONE WAY system contains more than 200 dyes and chemicals that have been carefully screened and pre-tested by the company’s product stewardship specialists against more than 15 eco-standards and other criteria. These include bluesign®1, Oeko-Tex®2, GOTS*, the 11 restricted substance groups classified under the Joint Roadmap Towards Zero Discharge initiative, 20 of the major brand RSLs (restructured substances lists) and other factors such as bioelimination.

Suitable products are first identified and shortlisted and individual cost, performance and environmental profiles subsequently calculated using the ONE WAY Calculator.

“The ONE WAY system is designed to help our customers balance the twin objectives of ecology and economy and enables them to see that more sustainable and efficient solutions do not have to come at a higher cost,” says Clariant’s Head of Product Marketing, Textile Chemicals, Emrah Esder.

Test data confirms accuracy of calculations by Clariant’s ONE WAY tool Clariant’s focus is on the development of innovative products that improve processes by saving resources, employing more renewable raw materials, maximizing safety and reducing emissions and waste.

Fong’s shares these goals, and seeing the potential value to the industry of the ONE WAY system, suggested carrying out trials of the latest low temperature pretreatment processes for fabric dyeing – including Clariant’s own solution called BLUE MAGIC – on its latest high energy, low consumption Jumbotec dyeing machine.

The bleaching pretreatment of fabrics prior to dyeing is an essential step in removing impurities and increasing both whiteness and hydrophilicity, allowing the dye to penetrate more deeply into the fibers so that the colors are more vivid.

The test data very closely matched the initial Clariant calculations using the new ONE WAY Calculator. The tool allows for the evaluation of the environmental profile of given production processes, using relevant parameters such as dyes and chemicals, water, energy or time; differentiated by country, based on actual measurements of chemical oxygen demand (COD), biological oxygen demand (BOD), CO2 emissions, energy consumption, and water usage.

“The ONE WAY system helps mills and brand owners to develop innovative textile solutions that are both more ecologically and economically sustainable,” says Mr. Esder. “Both industry and consumers continue to push for less complex, more cost-efficient and sustainable manufacturing processes, and defending and supporting the toughest eco standards is our aim with ONE WAY.”

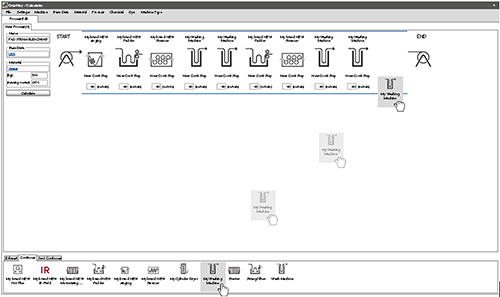

“Drag-and-drop” feature in Clariant’s ONE WAY Calculator allowing to simulate and compare production processes. (Photo: Clariant)

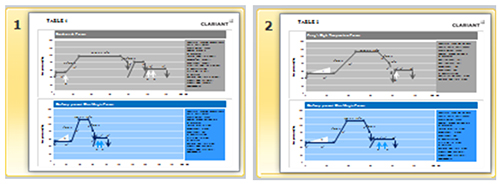

Benchmark process, Fong’s High Temperature process, Clariant’s Blue Magic process. (Photos: Clariant)

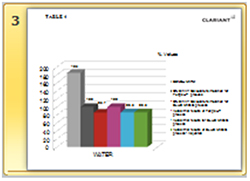

Comparison of water consumption in benchmark process, Fong’s High Temperature process, Clariant’s BLUE MAGIC process, and ONE WAY calculation of BLUE MAGIC process. (Photo: Clariant)

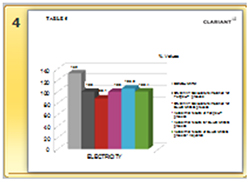

Comparison of electricity consumption in benchmark process, Fong’s High Temperature process, Clariant’s BLUE MAGIC process, and ONE WAY calculation of BLUE MAGIC process. (Photo: Clariant)

Comparison of process time in benchmark process, Fong’s High Temperature process, Clariant’s BLUE MAGIC process, and ONE WAY calculation of BLUE MAGIC process. (Photo: Clariant)

Comparison of CO2 in benchmark process, Fong’s High Temperature process, Clariant’s BLUE MAGIC process, and ONE WAY calculation of BLUE MAGIC process. (Photo: Clariant)

Clariant’s Blue Magic solution was tested on Fong’s latest JUMBOTEC 3-2T pretreatment and dyeing machine. (Photo: Fong’s)

*BELOW LIMIT OF DETECTION.