sunliquid® - converting straw to biofuel

PlayReducing dependency on fossil fuels and promoting local fuel production

In the face of climate change and dwindling reserves of fossil fuels, the search is on for environmentally compatible alternatives. Automotive sector consumes around 50% of the world’s crude oil production. With sunliquid®, Clariant has developed a process to produce cellulosic ethanol that is a second-generation biofuel distinguished by a first class climate balance.

ChallengeA WELL-KNOWN DILEMMA FOR ALTERNATIVE ENERGY: GROWING CROPS FOR FOOD OR FOR FUEL?Already existing biofuels have been produced from canola, corn or cereals – edible plants, rising the discussion concerning food or fuel resp. competition for arable land. To-date the manufacture of biofuels from non-edible biomass such as straw has been very costly due to expensive enzymes needed and energy-intensive processes.

The sunliquid® process utilizes only agricultural residues available in the various regions. In a newly developed biotechnological energy-self-sufficient process Clariant has succeeded in converting the difficult to access sugar in straw and other agricultural residues efficiently and economically into biofuel. With its optimized enzymes exactly tailored to the raw material being processed, the process delivers high sugar yields.

Solution

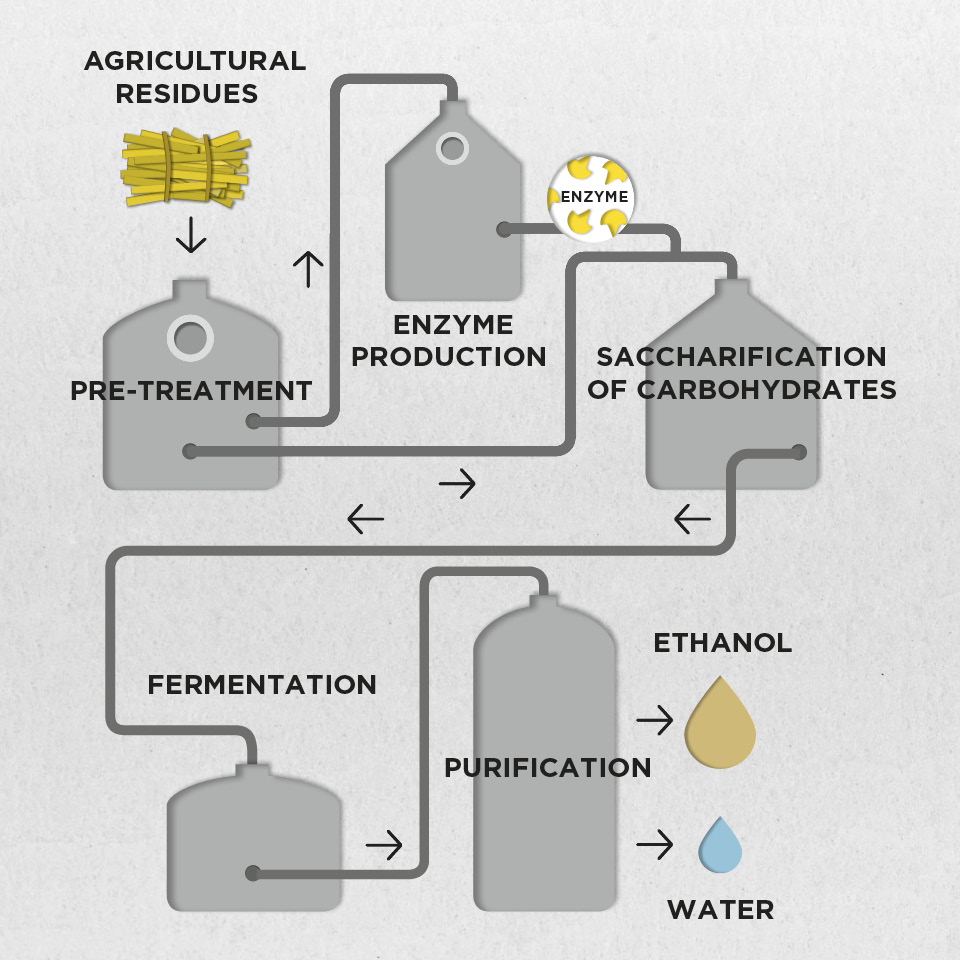

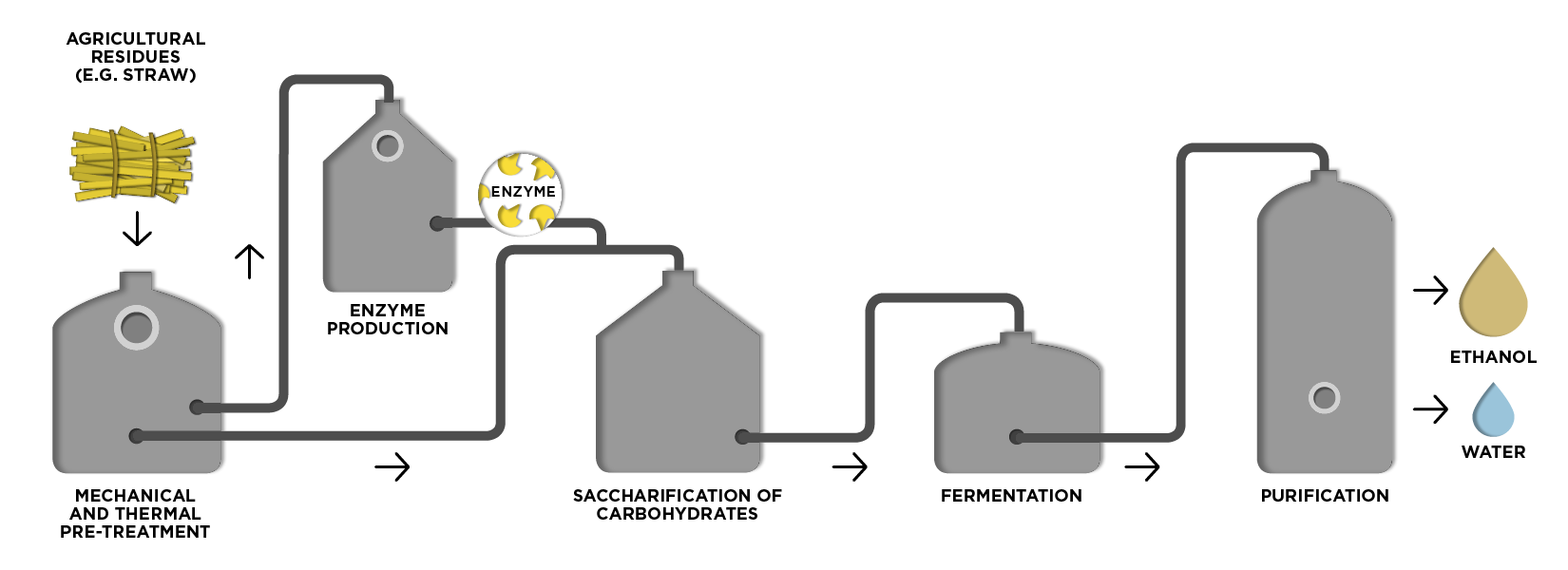

SUNLIQUID® PROCESS CONVERTS ONLY AGRICULTURAL RESIDUES INTO BIOFUEL

The sunliquid® process utilizes only agricultural residues available in the various regions. In a newly developed biotechnological energy-self-sufficient process Clariant has succeeded in converting the difficult to access sugar in straw and other agricultural residues efficiently and economically into biofuel. With its optimized enzymes exactly tailored to the raw material being processed, the process delivers high sugar yields.

Benefits

ENERGY SELF-SUFFICIENT PROCESS CREATES »GREEN JOBS« AND REDUCES DEPENDENCIES ON FOSSIL FUELS

REDUCED

CO2-EMISSIONS

Greenhouse gas emissions are reduced by 95% compared to fossil fuels.

INCREASED

BIOETHANOL YIELD

Produces 50% more ethanol than previous processes and is able to convert all types of sugar simultaneously.

ENERGY

SELF-SUFFICIENT

No additional energy is needed. The entire process energy originates from the lignin obtained as residue in the biomass.

PROCESS-INTEGRATED

ENZYME PRODUCTION

Minimizing procurement outlays and making the overall process more cost efficient.

Want to know more?

LET'S GET IN TOUCH

Please give us a call or contact one of our professionals from New Businesses – Biotech & Bio-based Chemicals.