Biofuels and Derivatives

Sustainable development of innovative technologies - The Group Biotechnology Center at Clariant

Clariant´s Group Biotechnology Center revolves entirely around industrial biotechnology. Focus is on progress and innovation based on the sustainable use of renewable resources.

Fossil resources are becoming scarcer and prices are rising. Politicians worldwide have set high targets in terms of environmental and climate protection. But: 95% of all industrially manufactured goods currently depend on the availability of oil. What does this mean? Only by developing sustainable solutions based on renewable resources can we reduce dependence on oil and at the same time assume responsibility for our environment and our fellow beings.

Clariant´s Group Biotechnology has set itself this goal – efficient and sparing use of natural resources in order to create more quality of life for humans and the environment. We see sustainability as all-embracing – ecological, economical und social.

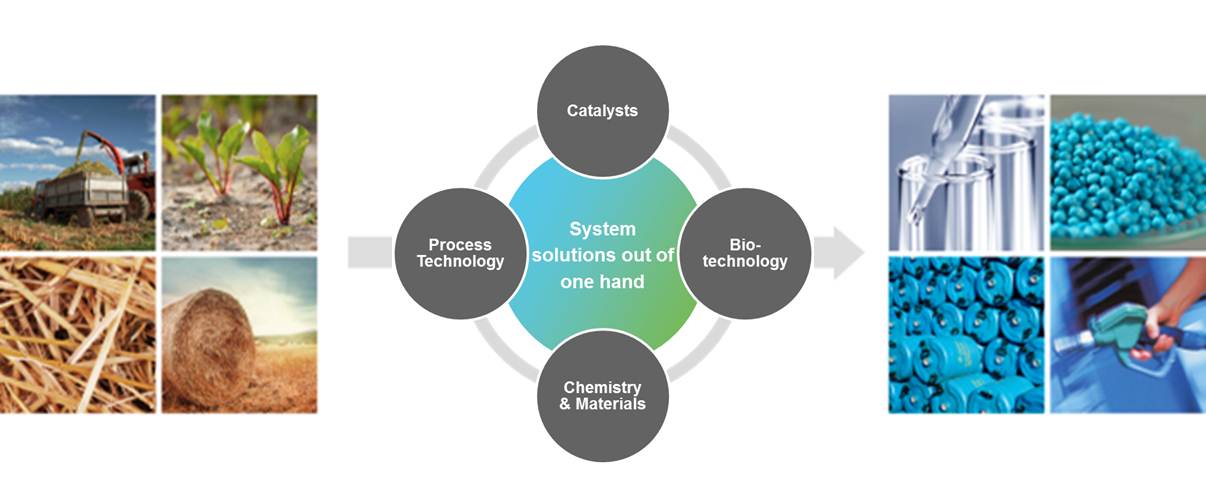

Our scientists make use of both their biotechnological expertise and the many years of experience in the chemical industry. Building on our 4 technology platforms catalysis, process technology, chemistry & materials and biotechnology, we can offer our customers one-stop system solutions for sustainable resources.

Our technologies and products

We create solutions for biocatalysis and biorefining.Our innovative focus is on energy and resource-efficient development and production of bio-based chemicals and fuels.

Biorefineries process biomass to produce a wide variety of products. The biorefinery concept promotes sustainable and high-value use of biomass. Using optimized biocatalysts, renewable feedstock undergoes selective and high-yield conversion into products such as fuel or basic chemicals.

We develop highly-specific biocatalysts based on biotechnological processes. These enzymes are highly optimized to the required process and reaction conditions. Using our in-house high-throughput screening unit, we can also carry out fast and efficient selection of suitable organisms, as well as quickly optimizing strains in line with new application requirements. Initial upscaling takes place in the pilot plant at our Munich-based research center.

We have a major strategic interest in developing such commercially competitive system solutions. By combining our core competencies of biocatalytic biomass conversion, chemistry & process technology, we generate innovative and profitable processes for manufacturing higher-quality products and by-products.

In recent years, we have for instance developed our sunliquid® process to produce cellulosic ethanol from renewable lignocellulosic feedstock, such as agricultural residue. This innovative and efficient process makes it possible to produce cellulosic ethanol with low CO2 emission levels (approx. 5 - 10% compared with fossil fuel) and creates no competition for food and feed resources. Find out more about our Sunliquid® process!

There are no articles related to this context.