Solving burning problemsPLASTICS IN E&E PRODUCTS HAVE TO BE

PROTECTED FROM FIRE

Plastic components connected to electrically live metal parts tend to burn easily and must comply with strict fire safety regulations. Therefore electronic devices have to be protected by flame retardants, which prevent or delay the development and spread of fires in various ways. With Exolit® OP Clariant offers a product family of tailor-made flame retardants based on non-halogenated organic phosphorus compounds which are a safe and environmentally compatible alternative to traditional ones. We’ve been developing and advancing this technology for over two decades. This effort resulted in more than 500 patents or patent applications globally.

ChallengeHELPERS FOR BURNING PROBLEMS CANSo-called halogenated flame retardants are under debate: during a fire, corrosive smoke gases can be released. Decomposition products such as halogenated dioxins can be produced and some halogenated flame retardants themselves are suspected of being hazardous to health.

SOMETIMES BE DANGEROUS THEMSELVES

x

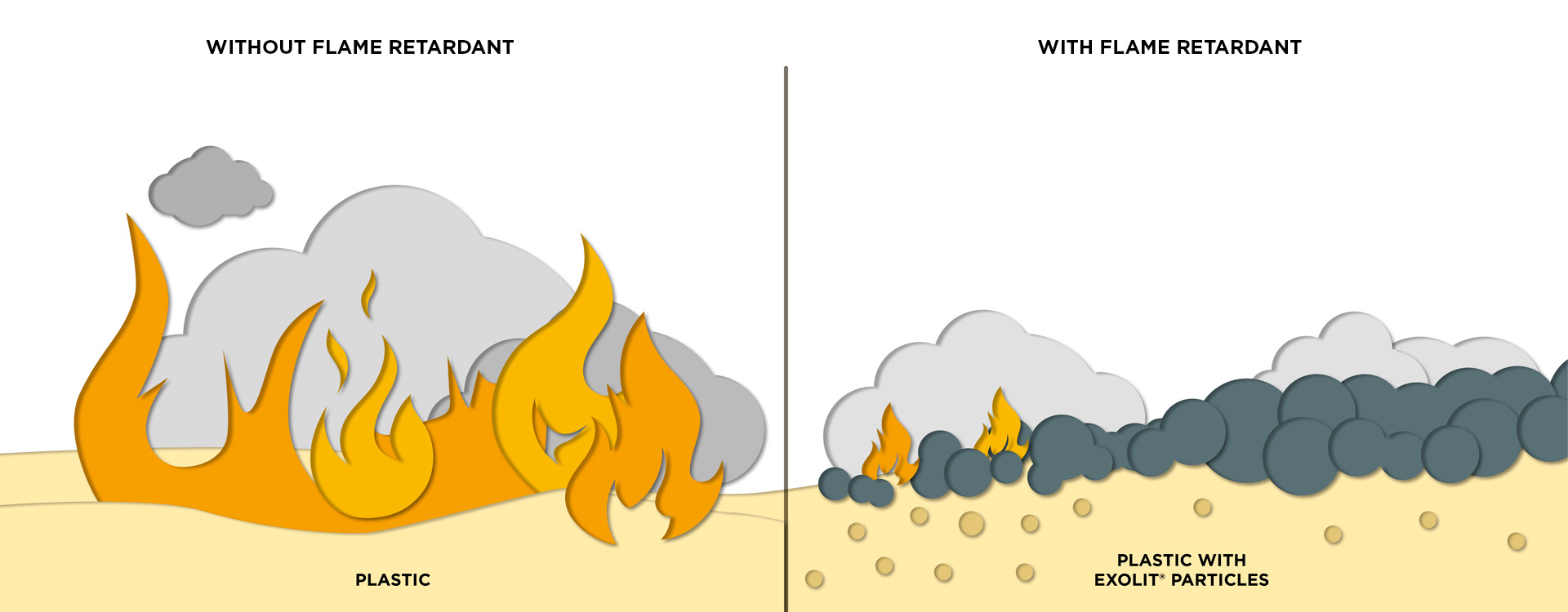

SolutionEXOLIT® OP PRODUCT FAMILY QUENCHES FIRE BEFORE IT STARTSThe latest Exolit® OP series is based on non-halogenated organic phosphorus compounds. Extensive toxicological tests along their life cycle in plastic have demonstrated their favorable environmental profile. When plastic containing Exolit® OP burns, it releases gases that cause burning plastic to foam and rapidly form a protective layer of foamed char which itself is no longer combustible. This protective layer both isolates the underlying plastic that has not yet burned against heat, and at the same time keeps out the atmospheric oxygen.

x

Benefits

A BROAD RANGE OF SOLUTIONS FOR EVERY NEED -

THE SAFE AND ENVIRONMENTALLY COMPATIBLE ALTERNATIVE

LESS AGGRESSIVE SMOKE

If a fire does occur, much less aggressive smoke is produced

PREVENTION OF SHORT CIRCUITS

Less fire risk in current-carrying metal parts in contact with plastic

Want to know more?

Let's get in touch

Please give us a call or contact

one of our professionals from

BU Additives – Flame Retardants.

x