Next-generation catalysts

FOR PURIFYING EXHAUST GAS

Concrete is the most widely used construction material in the world, but generates emissions from the clinker burning process. Thanks to the innovative zeolite catalyst technology from Clariant, the poisonous pollutants can now be purified almost completely and released into the environment.

Challenge

Cement production process generates harmful emissions

Cement is the main component of concrete, which is the most widely used construction material in the world. But throughout the production process, a significant amount of harmful emissions are generated.

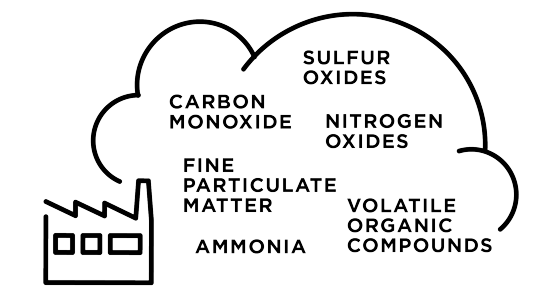

The pollutant emissions include fine particulate matter, nitrogen oxides and ammonia, volatile organic compounds, carbon monoxide and sulfur oxides.

Solution

A COMBINED CATALYTIC PROCESS FROM CLARIANT CAN REDUCE THESE EMISSIONS BY UP TO 90 PERCENT AND MORE

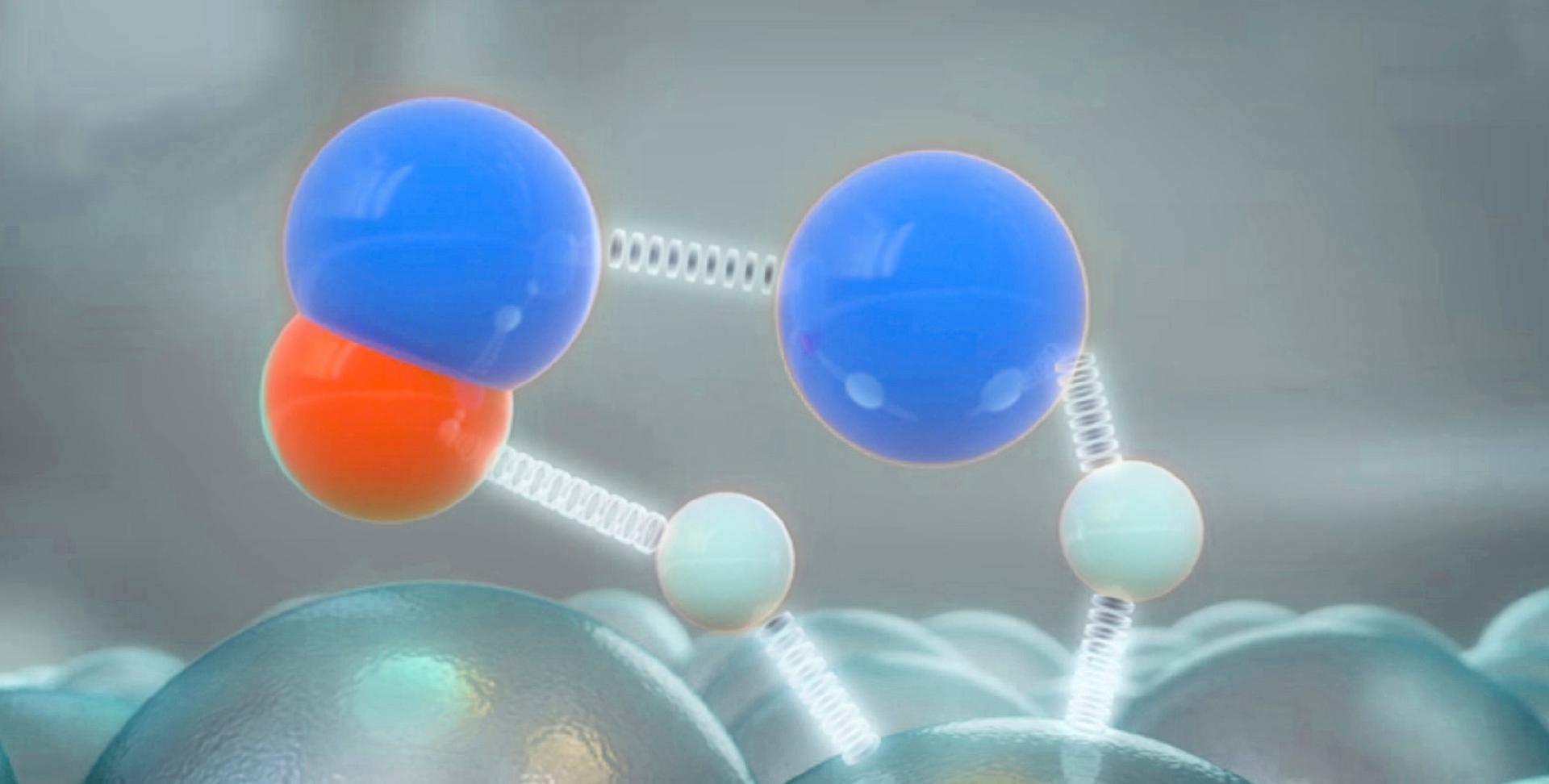

In the first stage nitrogen oxides and ammonia react on a catalytic layer, where they bind to the iron active centers. The molecules interact with each other forming water and harmless nitrogen.

In the next stage remaining organic contaminants and carbon monoxide are eliminated by catalytic oxidation. For this Clariant has developed an innovative ceramic honeycomb catalyst with an activated zeolite-coated surface.

The zeolite matrix provides durable protection against dust, sulfur oxides, and moisture which in conventional catalysts result in a fast deactivation. This key innovation enables the catalyst to survive under the harsh conditions of the process.

Solution

A COMBINED CATALYTIC PROCESS FROM CLARIANT CAN REDUCE THESE EMISSIONS BY UP TO 90 PERCENT AND MORE

In the first stage nitrogen oxides and ammonia react on a catalytic layer, where they bind to the iron active centers. The molecules interact with each other forming water and harmless nitrogen.

In the next stage remaining organic contaminants and carbon monoxide are eliminated by catalytic oxidation. For this Clariant has developed an innovative ceramic honeycomb catalyst with an activated zeolite-coated surface.

The zeolite matrix provides durable protection against dust, sulfur oxides, and moisture which in conventional catalysts result in a fast deactivation. This key innovation enables the catalyst to survive under the harsh conditions of the process.

Benefits

Toxic pollutants can be purified almost completely

PURIFICATION

OF EMISSIONS

Zeolite technology reduces pollutants by 90% or more

HIGH ACTIVITY AND EFFECTIVENESS OF CATALYST

Enables combustion efficiency of the precious metal catalyst

MEETING

REGULATIONS

Required standards for hazardous air pollutants in cement plants can be met

Want to know more?

LET'S GET IN TOUCH

Please give us a call, contact

one of our professionals from

BU Catalysts or learn more about

our Zeolite Powders here.