New Biofuel Feedstocks Demand New Purification Strategies

NEXT-GENERATION ADSORBENTS

HELPING PRODUCERS OF ALTERNATIVE FEEDSTOCKS

To Maximize Their Throughput and yields

Complexities of New Feedstocks

With the “Renewable Energy Directive” RED II already in place since this year, biofuel producers, hoping to meet the stringent new requirements, are facing two main feedstock challenges: availability and quality (Fig. 1).

New feedstock variants, in limited supply and with a diverse range of impurities, greatly impact filterability during pre-treatment, and, thereby, production yields and profits. Overcoming these problems requires novel adsorbents and innovative technical strategies that can facilitate high throughput purification.

Feedstock Availability 2020 - 2030 Main Quality Challenges Second-Generation Feedstocks UCO/RUCO Moderate to good

Alkaline metals, metals, oil stability, polymers

Animal fat

(category I & II)Moderate N-content, metal content, acidity Advanced Feedstocks POME Moderate Acidity, alkaline metals, metals,

P-compoundsExtracted oil from bleaching earth Low Purest feedstock (already treated), some heavy metals from previous purification Algae Low Metals, polymers Figure 1. Availability and quality challenges of new feedstock variants used for biofuel production. (UCO = used cooking oil, RUCO = repurposed used cooking oil, POME = palm oil mill effluent).

Pre-Treatment of Alternative Feedstock

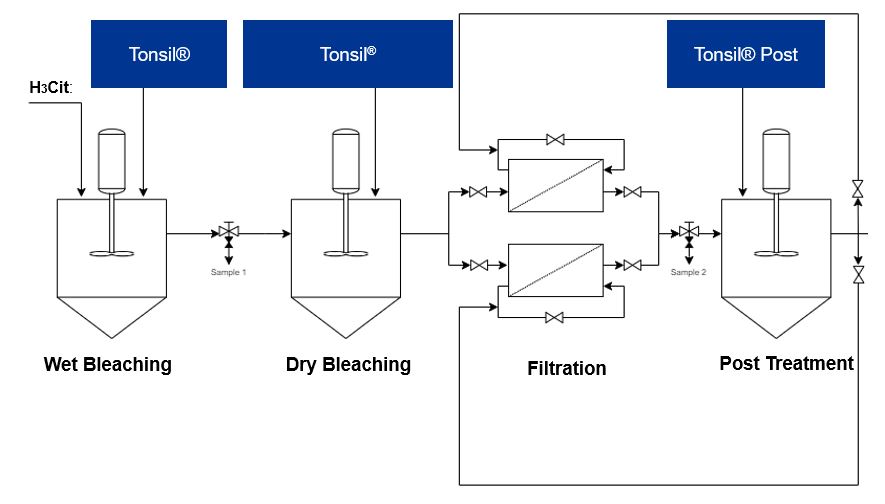

Figure 2. Pre-treatment of alternative feedstocks, such as FAME or HVO, requires different adsorption and filtration techniques.

In a feedstock market that is stretched to its limits, quality and availability are in direct relationship. Insufficient choice and supply of feedstock have forced producers to use lower qualities than their facility designs allow, adding considerable stress to their units. On the other hand, being able to “tame” difficult-to-treat feedstocks would give producers a strong competitive advantage.

In the case of fatty acid methyl esters (FAME) or hydrotreated vegetable oils (HVO), the feedstocks’ regulatory compliant specifications mean that the process remains stable. However, problems are found further upstream, in the pre-treatment unit. With such alternative feedstocks, there should be a fresh focus on two important steps: adsorption and filtration (Fig. 2).

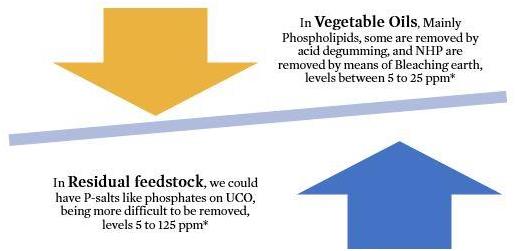

An adsorbent is required to reduce many undesirable substances that cannot be removed in the degumming steps. Compared to vegetable oils, alternative feedstocks can contain higher levels of different species of contaminants, such as phosphorous compounds, that can greatly affect efficiency as well as the adsorption step (Fig. 3).

Figure 3. Contaminant content and removal challenges of residual (alternative) feedstock compared to vegetable oils.

Filtration

Besides the batch reactor, the filter is one of the most important sections of a pre-treatment unit. Conventionally, horizontal leaf filters (Niagara type) were used with screens that had larger pores than modern designs in order to allow maximum flowthrough during filtration.

Since a filter cake is formed with the adsorbent, its quality and development are critical. A stable and, especially, homogenous filtration ensures that contaminant removal is spread across the entire filter cake and leads to more efficient use of the adsorbent.

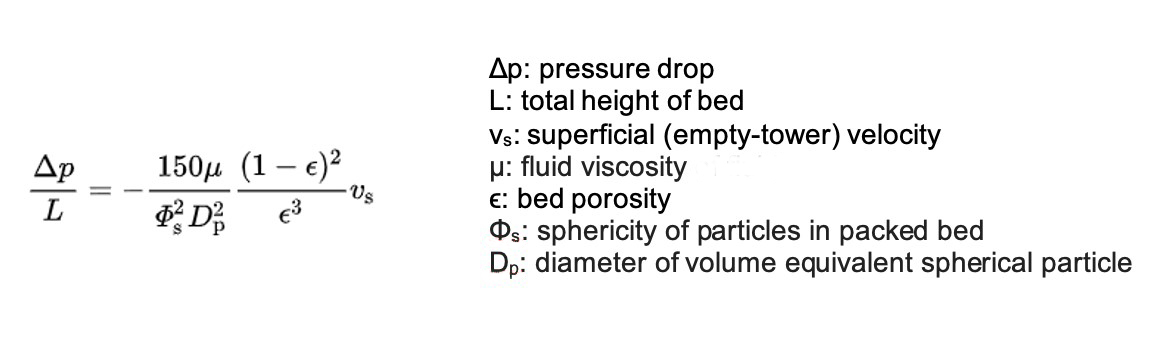

Assuming a parallel channel through the filter cake, filtration efficiency is ideally defined by the Kozeny-Carman equation (Fig. 4). The material inside the cake should improve porosity (µ).

Figure 4. Evaluating filtration efficiency based on the Kozeny-Carman equation.

Next-Generation Adsorbents

Due to the aforementioned factors, adsorbents must not only offer improved removal of a great variety of contaminants, but also enhanced filtration efficiency. Such qualities are evident with next-generation adsorbents, such as Clariant’s Tonsil™ 919X FF and the newly launched Tonsil™ 719X FF series. The highly activated, selective adsorbents are proven to considerably facilitate pre-treatment of alternative feedstocks and help overcome filtration challenges caused by feedstock viscosity (µ) and contaminants featuring high molecular weights.

Another factor affecting the pre-treatment unit’s throughput is adsorbent dosing. As alternative feedstocks have a complex contaminant profile and higher content levels that are more difficult to remove than vegetable oils, adsorbent dosing usually needs to be significantly increased by 30 to 80% or higher. A highly activated and selective adsorbent not only helps to reduce adsorbent dosage, but also to increase plant throughput and to minimize oil retention in the cake. These aspects are critical to the total cost of ownership (TOC) in the adsorption process, and, thereby, the overall production costs.

Advantages for Biofuel Producers

Feedstock Clariant Adsorbent Filtration Time

of First Pass

(seconds)Total Metal*

(mg/kg)Palm oil mill effluent (POME) Tonsil™ 919X series 93 < 5 Tonsil™ 719X series 65 Animal fat Tonsil™ 919X series 440 Tonsil™ 719X series 287 *earth-, alkaline, Si, P, Fe, Al

Considering the total cost of ownership, next-generation adsorbents can make the difference between not being able to filter at all and having favorable throughput. Latest lab test results have demonstrated approximately 35% shorter filtration times (first pass) with new generation adsorbents than with past generation (Fig. 5). This is a major competitive advantage for biofuel producers, because not only can it significantly broaden the scope of feedstocks they can operate, but also ensure high throughput production and minimize oil retention in the spent adsorbent.

Figure 5. R&D lab test results comparing filtration times of generic present generation adsorbents vs. next-generation adsorbents in POME and animal fat.