Mitigation in 3-MCPD and GE

All around the world, people have been using oils for eating and cooking for thousands of years.

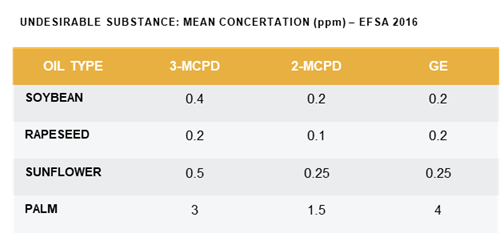

Raw edible oils generate a mixture of desirable and undesirable substances. They are therefore purified and refined using different techniques.One of the undesirable substances is not formed until the oil is being purified: a chlorinated alcohol by the name of 3-MCPD (3-chloro-1,2-propanediol or 3-monochloropropanediol) in the form of its fatty acid esters. These esters form most notably in palm oil, reflecting among other things the quality of the raw oil.

How toxic is 3-MCPD and how is the bioavailability of its fatty acid ester?

In animal experiments with rats 3-MCPD led to infertility, weakened the immune system and induces tumors of kidneys, testes and mammary glands. 3-MCPD is classified as possibly human carcinogen. By means of animal experiments a nearly complete hydrolysis of the 3-MCPD fatty acid esters (and also glycidyl fatty esters) in the gastrointestinal tract can be assumed.

Therefore, a tolerable daily intake (TDI) of max. 2 mg 3-MCPD/kg body weight is still applied.

For further information on this topic please see the website of the EFSA (European Food Safety Authority).

______________________________________________

Article from OFI Magazine

Clariant's solution for 3-mcpd and ge mitigation

Clariant’s Tonsil™ Low 3-MCPD variants provide highly active bleaching earths that efficiently minimize the level of 3-MCPD and its esters in palm oil.

At the same time, they gently remove pigments, gums and other substances that can unfavorably affect the appearance, taste, odor and shelf life of edible oils.

benefits

HIGHLY ACTIVE

Minimal dosing, maximum efficiency

PROTECTS CONSUMERS

Minimizes harmful 3-MCPD and preserves nutrients

Optimized total cost of ownership

...due to the bleaching performance and fast filtration properties of the bleaching earth

TAILOR-MADE

Adaptation to processes and specifications, optimum total cost of ownership (TCO)

Highly resource-efficient

Perfect logistics for local requirements

Consistent quality

Thanks to Clariant’s »selective mining« process

Tonsil™ bleaching earths are made from bentonite clay and consist of fine powders that, when added in small amounts to the oil, have the ability to adsorb the majority of its impurities.

The effectiveness of the adsorption process depends on various natural and modifiable factors, such as particle and pore size, surface area and potential for cation exchange.To ensure good results, these factors must be accurately adjusted to the oil and purification process used.

This process can vary in many parameters, from temperature and pressure to filters and cycle times; parameters which must all be taken into consideration for achieving optimal purity, high outputs and high levels of efficiency.

Tailor-made solutions

Clariant has the ability to reproduce a customer's purification process on a laboratory scale and accurately tailor its Tonsil™ Low 3-MCPD solutions to customer needs.

This allows these solutions to strike the right balance: They combine minimization of 3-MCPD with maximized removal of unwanted carotenoids, peroxides, phospholipids and heavy metals, while also leading to optimized costs of ownership.