Iron Ore -

Complete beneficiation solutions

with flotation reagents,

agglomeration additives and filter aids

Clariant Mining Solutions collaborates with mines globally to develop and provide chemical solutions that work in conjunction with other operational upgrades to reach an optimum cost-performance balance. Our iron ore experts work with mine producers in the key iron ore regions of the world, addressing technical challenges and helping them stay competitive. With comprehensive global logistics, localized production and on-site service, Clariant is able to ensure continuity of supply and help overcome technical challenges regarding production quality, operational targets and production costs to our iron ore customers, today and in the future as their needs grow.

Tailored chemical solutions

for different iron ore types and process conditions

Increased recovery and

utilizing our

concentrate quality

comprehensive range of collectors for the

flotation process

Improved throughput and reduced

with the selection

filter cake moisture

of the right filter aid product

Enhanced agglomeration process

with our binders for pelletizing iron ore fines

and sinter feed

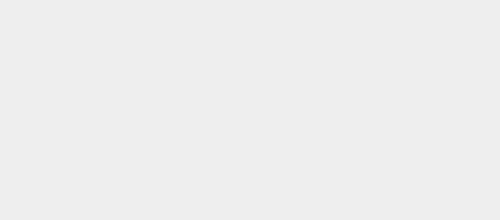

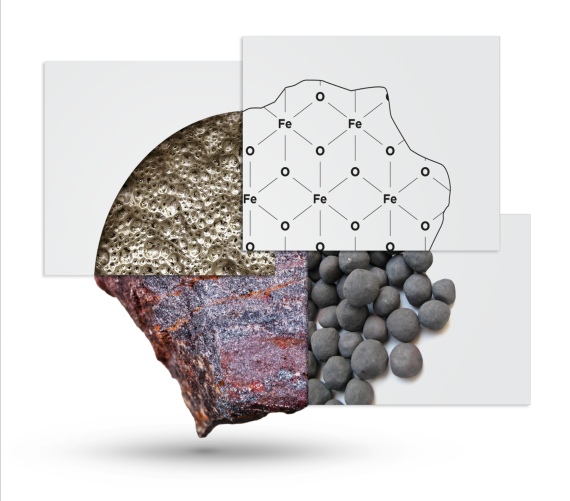

Clariant’s portfolio includes a comprehensive range of collectors and frothers for iron ore flotation to remove undesirable mineral impurities. The FLOTIGAM™ series includes ether amines, ether diamines and other cationic collectors for every iron ore flotation challenge. Our FLOTIGAM™ collectors are able to produce iron ore concentrate with low silica content by froth flotation, resulting in high purity concentrate, which is needed for steel production. Clariant’s iron ore technical experts and flotation specialists can work with your technical teams to develop customized solutions for your specific needs. From increased recoveries to lower contaminant grade, our portfolio delivers enhanced performance.

Designed to overcome processing and transport challenges related to moisture content, Clariant’s dewatering and filtering agents can deliver optimal moisture content without adding complexity to the process. Our FLOTICOR™ range consists of surfactant-based chemicals that allow for improved drainage across different filtrating and dewatering schemes. Our experts can help select the best product for your dewatering needs.

Clariant Mining Solutions has developed several types of binders and additives for the iron ore agglomeration processes. Our FLOTICOR™ PA series of binders includes high performance bentonite-based binders, hybrid binders and organic binders for iron ore pelletizing. Some of our solutions can increase the mechanical and chemical properties of the pellets and increase production rate while others also enable agglomeration of coarser mineral particles, resulting in savings in gridding costs and water usage.