Pour Point Depressants

Clariant‘s Pour Point Depressants: Crude and Fuel Handling Today

As leaders in the industry, Clariant Refinery Services offers a broad range of pour point depressants designed to meet the customer’s specifications in a variety of streams and applications like transport of crudes, middle distillates (including heating oil), heavy oils, waxy components and biodiesel or in marine diesel blends. Through constant innovation and applying the latest technologies, our expert teams can offer tailored PPD solutions for your application:

- bring crudes, middle distillates or marine fuel to specification

- improve transport and pumpability of especially waxy crudes

- Increase crude slate through PPD injection while unloading waxy crudes

Clariant’s global presence and local expertise allows us to provide customer-specific solutions to overcome oil treatment challenges.

Crudes and heavy fuel oils are complex mixtures of various hydrocarbons ranging from paraffins, aromatics, naphthenes, and resins to asphaltenes. Long chained paraffins tend to crystallize when cooled down, which leads to severe sedimentation. In order to prevent sedimentation or even blockage of pipelines, PPD formulations are added to keep the crude or heavy fuel oil moving. Clariant provides innovative solutions like DODIFLOW™ to help approach these challenges successfully.

Crudes are called either Opportunity Crudes or Challenging Crudes if they combine some properties, which require a special handling attention from the refineries. Those crudes often show a high Pour Point, high wax content, are mainly sweet and in most cases bought and sold on the spot market. Their lower costs in a refining process makes them a better economic option to improve refinery’s profitability. Before refining, Opportunity Crudes have to be treated to bring the Pour Points within pipeline and storage specifications. Our PPDs have been tested to successfully lower Pour Points of various crude oil qualities to improve handling and storage.

Name |

Region |

API* typical [°] |

WAT approx. [°C] |

PP untreated approx. [°C] |

PP treated approx. [°C] |

|---|---|---|---|---|---|

| Escravos | Nigeria | 35,6 | 24 | -3 | -12 |

| Okwori | Nigeria | 36,3 | 20 | 12 | -12 |

| Skarv Blend | North Sea | 37,2 | 30 | -12 | -27 |

| Okono | Nigeria | 40,8 | 21 | 15 | -12 |

| Yoho | Nigeria | 39,9 | 26 | 15 | -15 |

| Qua Iboe | Nigeria | 35,7 | 21 | 12 | -27 |

| Brent | North Sea | 37,8 | 0 | -24 | |

| Amenam | Nigeria | 38,7 | 23 | 15 | -30 |

| Norne | Norway | 31,0 | 39 | 21 | 6 |

| Triton | UK | 37,9 | -3 | -18 |

To avoid a significant rise in fuel prices and meet the new sulfur emissions restrictions, refineries are promoting or developing new fuel blends combining heavy and light streams. Ship owners who do not want or are not able to install expensive exhaust treatment equipment are starting to recognize the value of these hybrid fuels. These new marine diesel types have to be brought to Pour Point specification with PPDs. Clariant Refinery Services has followed this global emission reduction trend early on and developed a number of tailored additives for new types of marine diesel. Our experts and global laboratories help refiners combine their production streams ensure the final products are stable and marketable meeting the new regulations. We provide innovative products to reduce the pour point without reversion in our customer’s marine fuels.

Today, 20 percent of all produced crudes have high pour points and high wax levels. Most of them have to be transported by pipeline from bore hole to process plant, port storage or refinery. To overcome transportation problems different technologies are used. For pipeline transport, our pour point depressants are far more economical than other technologies. We offer several successful products to meet this challenge. Our experts work with you to ensure your crude transportation project gets the support it needs.

Diesel fuels and heating oil contain lower molecular weight paraffins with carbon numbers up to approximately C30. Fuels within this range can differ significantly in cold flow properties. Diesel cuts coming from Coal to Liquid or Gas to Liquid procedures show higher pour points than diesel coming from crude distillation. Some high waxy crudes lead to diesel cuts with high pour points. Pipeline specifications and local requirements may require the use of PPDs for such diesel fuels. All these different middle distillates require PPD which are optimized to the individual paraffine distribution. Clariant is specialized to develop these tailored PPD, aiming to use PPD in most economic injection rates. Whatever your challenge, we have the expertise and experience to help you meet it. Our experts are on hand to develop innovative solutions just for you.

There are many different types of biodiesel on the market. Some contain fatty acid methyl esters made by trans-esterification of vegetable oils, cooking oils or animal fats with an alcohol producing fatty acid esters while others are hydrocarbon based, e.g. produced in process similar to Fischer-Tropsch. Biodiesel is mainly used in standard diesel engines as blend or as pure fuel. Blends of biodiesel and conventional hydrocarbon-based diesel are labeled with a B-factor in most cases. Pour Point Depressants are used for higher B-contents (e.g. bio content > 20%) or when handling the pure substances, e.g. before blending or when transporting or storing pure biodiesel. B100 (pure biodiesel) is also used in some engines but needs pour point and cloud point modifications. Clariant has developed specially designed biodiesel PPD’s.

Information Download

Definitions, Measurements and Mechanism

Due to economic reasons, most refineries tend to use crude oils from a variety of sources. Depending on the origin of the crude and the conversion capabilities of the refinery that processed them, these fuels can differ significantly in their characteristics. Examples are wax and asphaltene content as well as API gravity. All of these have a significant impact on the physical properties and cold temperature behavior of the fuel.

Cooling down a sample of crude or residual fuel causes the formation of wax crystals, which in turn causes the oil to gel. Pour point is the lowest temperature at which a fluid is can be pumped before solidifying.

Standard test methods applied include ASTM D 97 / DIN ISO 3016 or ASTM D 5985.

This is the American Petroleum Institute’s (API) inverted scale for denoting the “lightness” or “heaviness” of crude oils and other liquid hydrocarbons.

Calibrated in API degrees (or degrees API) it is used universally to express the relative density of the oil.

Crude oils with:

- API° > 30 are termed light;

- between 22° and 30°, medium;

- below 22° as heavy and at

- API°< 10, as extra heavy.

Using the equation below, API° can be easily converted to specific gravity:

Specific Gravity = 141.5 / (131.5 + API)

WAT is defined as the temperature at which the first wax crystals begin to form in heavy fuel oils and crudes. The WAT can be determined by various methods including DSC, cross- polarized light microscopy and viscosity.

Pour Point Depressants – Mode of Action

Linear paraffins can form needle- or plate-like crystals which can agglomerate and create a three dimensional network solidifying the fuel. Pour Point Depressants act as a wax crystal modifier. Modification is achieved by nucleation, co-crystallization and anti-agglomeration, which results in reduction of the size and shape of wax crystals. Wax-crystals are not inhibited but modified in a way that they do not precipitate.

In general PPDs consist of:

- Linear alkyl chains which can co-crystallize with the long chain paraffins in the oil

- A polar component which retards further wax crystal growth

- Very large polymer molecules which inhibit the formation of large wax crystals

The performance of a Pour Point Depressant does not only depend on the concentration and distribution of linear n-paraffins, but is also influenced by Asphaltenes and other components.

Clariant’s DODIFLOW™ micro-dispersions as well as the liquid DODIFLOW™s feature excellent temperature handling characteristics for terminal applications, cold regions or EX-protected zones. DODIFLOW™ additives also reduce the need to use expensive cutter stocks.

Picture: Crystal Modification of a wax by Pour Point Depressants

ASTM D97

Standard Test Method for Pour Point of Petroleum Products

ISO 3016

Petroleum products, Determination of pour point (EU)

IP 15

Petroleum products - Determination of pour point (US)

GOST 20287

Petroleum products, methods of test for flow point and pour point (GUS)

ASTM D5853

Standard Test Method for Pour Point of Crude Oils

IP 441

Determination of the pour point of crude petroleum

ASTM D5949

Standard Test Method for Pour Point of Petroleum Products (Automatic Pressure Pulsing Method) [Phase Tech 70Xi]

ASTM D5950

Standard Test Method for Pour Point of Petroleum Products (Automatic Tilt Method) [PAC CPP 5Gs]

ASTM D5985

Standard Test Method for Pour Point of Petroleum Products (Automatic Rotational Method) [PSL PPT 45150]

ASTM D6892

Standard Test Method for Pour Point of Petroleum Products (Robotic Tilt Method) [PAC HCP 852]

ASTM D7346

Standard Test Method for Pour Point of Petroleum Products (Automatic Pressure Differential Method) [PAC MPP 5Gs]

Products

We have developed a variety of DODIFLOW™ Pour Point Depressants customized for specific applications. Please contact us to find the DODIFLOW™ product which best suits your needs. Recommendations are available on request depending on your specific crude challenges or after individual testwork in one of our laboratories.

Clariant Pour Point Depressants enable customers to:

- Treat discounted, high paraffin crudes & residual fluids

- Reduce costs,associated with blending cutter stock with high paraffinic oils

- Improve pipeline flexibility by allowing transportation of highly paraffinic oils without heating

- Win flexibility by increasing No. of crude slates.

- Reduce heating in fuel distribution system

- Avoid removal costs of solidified paraffin waxes

- Reduce pumping costs

- Upgrade value of refinery residues / heavy fuels

- Bring Marine Diesel, especially DMA and DMB to Pour-Point-specification

- Use Biodiesel of all generations, even in higher concentration or pure.

Pour Point Depressants with improved handling properties

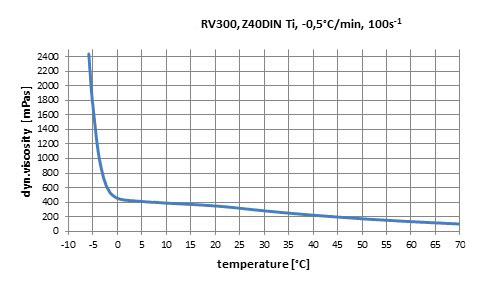

Most Pour Point Depressants are solid or waxy at room temperature and have to be warmed up before used. The time effort and complexity to use a PPD increases. It is difficult to use heatable systems in special areas, like EX-zones or on board. Fluid PPDs at ambient temperature can solve the problem. The table below shows an example of such a highly effective PPD in the DODIFLOW™ range, which will not be solid before -6 °C and remains pumpable down to this temperature region. Other system you can get on request.

To ensure that our customers are obtaining the most benefit from the additive, our service team offers a comprehensive analysis and characterization of the oil / oil blends. These include - but are not limited to - S.A.R.A., yield stress, rheological measurements etc. Based on the data received from these analyses, Clariant will select and recommend the best performing PPD for your needs.

Graph shows viscosity curve of a selected PPD with improved handling conditions

Contact

Our experts can help you choose from a selection of PPDs developed to improve fuel performance. Contact us for more information about how our pour point depressants can increase efficiencies and improve your profitability.