Chromium-free

HySat 320 catalysts

Upgrade your hydrogenation processes with high performing, sustainable chromium-free catalyst

The chemical industry is at an inflection point when it comes to developing more sustainable production processes. Conventional copper chromite (CuCr) catalysts used ubiquitously for decades in key chemical processes like hydrogenation can contain hazardous chromium in the hexavalent oxidation state (Cr(VI)). This poses significant issues for safe handling, disposal, and long-term viability as environmental restrictions on Cr(VI) continue to tighten.

Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and other global regulations are significantly tightening limits on usage of hazardous hexavalent chromium substances commonly relied upon in catalyst applications. With limits decreasing down to just 1 ton per year (1), there is increasing and urgent pressure across the global chemical industry to explore and adopt alternative, eco-friendly chromium-free catalyst solutions instead of continuing to depend on conventional copper chromite options.

This drive is accelerated by growing public awareness and concerns over the health and environmental impacts of persistent, bio-accumulative toxins combined with tightening waste and emission policies. Producers require access to effective substitutes that uphold productivity without compromising sustainability.

Developing and validating high-performance 100% chromium-free solutions

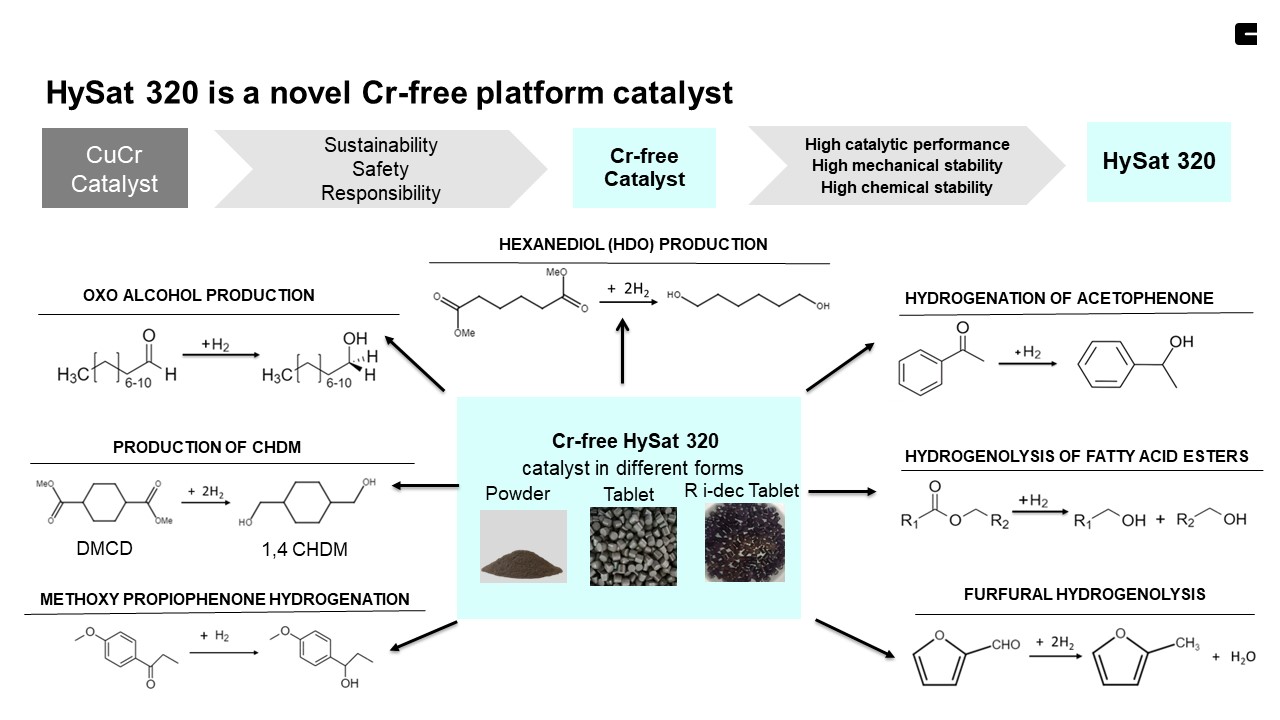

Clariant stepped up to meet this catalyst innovation challenge by leveraging years of research and technical expertise in catalysis. Our highly skilled R&D team at the R&D Center Heufeld developed HySat 320 - an innovative chromium-free catalyst uniquely formulated to rival or exceed the performance benchmarks set by traditional copper chromite catalysts still widely used throughout the industry in a broad range of applications.

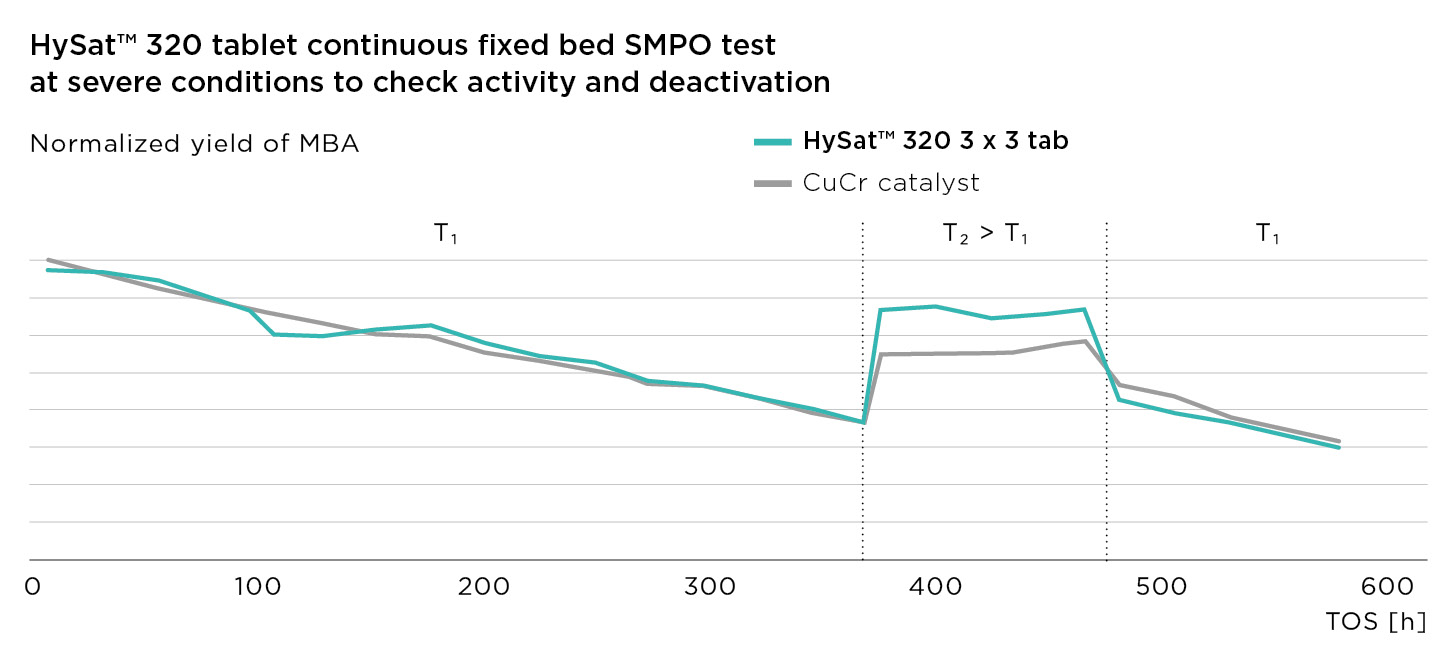

Before introducing this breakthrough solution to market, we rigorously tested and optimized HySat 320 across long-term lab trials as well as pilot demonstrations in active customer production facilities. These extensive evaluations focused both on validating efficiency improvements through controlled benchmarking, as well as ensuring seamless integration into existing process equipment and configurations leveraged by chemical producers.

Proof of efficiency through superior performance benchmarks

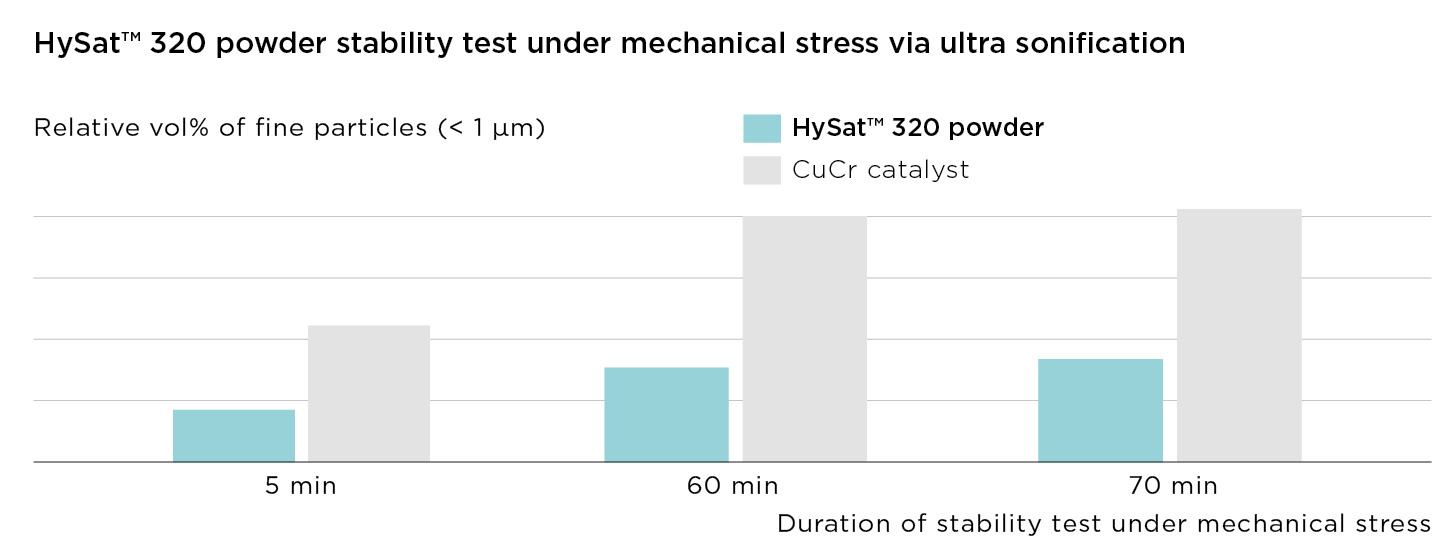

Repeated head-to-head comparisons under intense operational conditions have proven HySat 320’s superior catalytic activity, selectivity and longevity compared to conventional copper chromite catalysts. For example, for acetophenone hydrogenation applications, HySat 320 tablet achieved over 10% higher yields while maintaining or improving upon crucial mechanical stability of tablets that impact reuse and changeout frequency.

Customer production trials also showed HySat 320 powder fulfilling or exceeding efficiency expectations while easing operational pain points like filterability if the catalyst is used as a powder - a benefit known so far only for copper chromite catalysts. This demonstrates the large-scale viability and process improvements accessible by transitioning to HySat 320 as a drop-in catalyst replacement for powder catalyst applications.

By delivering comparable or superior performance to legacy chromium catalysts while eliminating their steep environmental and health hazards, HySat 320 provides chemical companies an easily adopted solution to transform conventional processes for a more sustainable future – one aligned with both shareholder value creation and tightening regulations. Clariant offers end-to-end implementation support including efficiency benchmarking to streamline adoption efforts.

Realizing a more sustainable chemical industry

Clariant’s chromium-free catalyst innovation empowers companies across the chemical value chain to make substantive, measurable contributions to improving global environmental and health goals for the better in a broad range of applications. As regulations and societal expectations tighten, solutions like HySat 320 ensure the longevity and license to operate for chemical producers without forcing a compromise between sustainability and productivity.

By taking the lead in commercializing access to high-performing sustainable catalyst alternatives at scale, we are enabling the global chemical industry to uphold both profitability and environmental principles. Companies seeking to tangibly improve their sustainability footprint without sacrificing efficiency benchmarks are encouraged to contact our technical experts at Clariant to evaluate qualifying chromium-free catalyst solutions for their unique production environments. We at Clariant have the expertise and innovative products to help transition processes for an improved sustainability outlook.

(1) REACH regulation (no date) Environment. Available at: https://environment.ec.europa.eu/topics/chemicals/reach-regulation_en (Accessed: 10 April 2024).

This blog post is based on the scientific session "Replacing Cu/Cr-based catalysts with a novel Cr-free catalyst in a variety of industrial hydrogenation applications" presented by Dr. Huiqing Song on March 14th 2024, at the 57th Annual Meeting of German Catalysis Researchers in Weimar, Germany.

Huiqing Song is an expert scientist in catalysis research at Clariant's Hydrogenation Department. He earned his Ph.D in Chemical Engineering from the University of Munich in Germany. Dr. Song has over 7 years of industrial experience innovating novel catalyst solutions. His areas of expertise encompass catalyst design, characterization, and testing focused on developing sustainable alternatives for the chemical industry across hydrogenation, dehydrogenation, and hydrogenolysis applications.