Clariant Oil Services Improves Separation Performance on West African FPSO

Benefits

- 30% Reduction in chemical usage and logistical costs

- Annual savings of $180,000

- Previously unacceptable produced fluids now meet specifications

- 30% Improvement in export crude BS&W and salt content

Background

A major oil and gas FPSO operator in West Africa was experiencing separation difficulties due to naphthenate and wax stabilized emulsions that resulted in unacceptable export oil quality. The FPSO produces 210,000 bbls of 29.9o API crude, together with 6,300 bbls of water per day in a water depth of 1,200m. Fluids are produced from 11 wells via a number of subsea completions and combine into a single manifold on the FPSO. The process system comprises three separators and two de-salters aligned in series with typical temperatures ranging from 49oC to 60oC and finally 50oC.

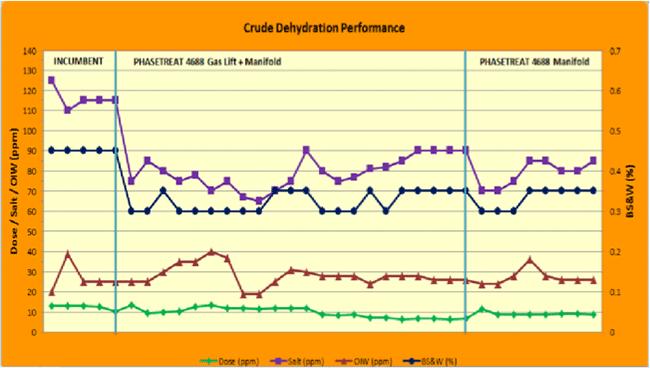

The incumbent demulsifier was injected at 13ppm with a 50:50 split between gas lift and manifold and was only able to dewater the crude to a BS&W of 0.45% with a salt content of 115ppm.

Clariant Oil Services Solutions and Value Delivered

Clariant Oil Services has extensive experience in treating naphthenic crudes and, in conjunction with the operator, fluid separation experts were mobilized to the field to perform bottle tests to screen potential candidate products.

During the field trial, Clariant Oil Services’ PHASETREAT 4688 – developed specifically for this application – was observed to be faster acting, generated cleaner interfaces and maintained the excellent performance while only injected into the manifold, when compared to the incumbent. The dose rate of PHASETREAT 4688 was reduced to 7ppm during the trial; however, this was optimized in the field to 9ppm.

PHASETREAT 4688 was able to significantly reduce BS&W and salt content of the crude to meet the specification of the operator, while generating a cost savings of approximately $180,000 through reduced dose rate and logistics costs. The quality of the produced water was unaffected by the change and remained below the specification.

This information corresponds to the present state of our knowledge and is intended as a general description of our products and their possible applications. Clariant makes no warranties, express or implied, as to the information’s accuracy, adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use of this information. Any user of this product is responsible for determining the suitability of Clariant's products for its particular application. *Nothing included in this information waives any of Clariant’s General Terms and Conditions of Sale, which control unless it agrees otherwise in writing. Any existing intellectual/industrial property rights must be observed. Due to possible changes in our products and applicable national and international regulations and laws, the status of our products could change. Material Safety Data Sheets providing safety precautions, that should be observed when handling or storing Clariant products, are available upon request and are provided in compliance with applicable law. You should obtain and review the applicable Material Safety Data Sheet information before handling any of these products. For additional information, please contact Clariant.

*For sales to customers located within the United States and Canada the following applies in addition: NO EXPRESS OR IMPLIED WARRANTY IS MADE OF THE MERCHANTABILITY, SUITABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE OF ANY PRODUCT OR SERVICE.

Copyright © Clariant International Ltd, 2012.