Discover Tonsil™ APT

What if Tonsil™ APT makes your life easier in day to day opertations of BTX purification?

State-of-the-art clay catalysts for Aromatic Complexes

Pure aromatics are the starting material for various products such as PET, Polystyrene, plastic fibres, and other plastic materials.

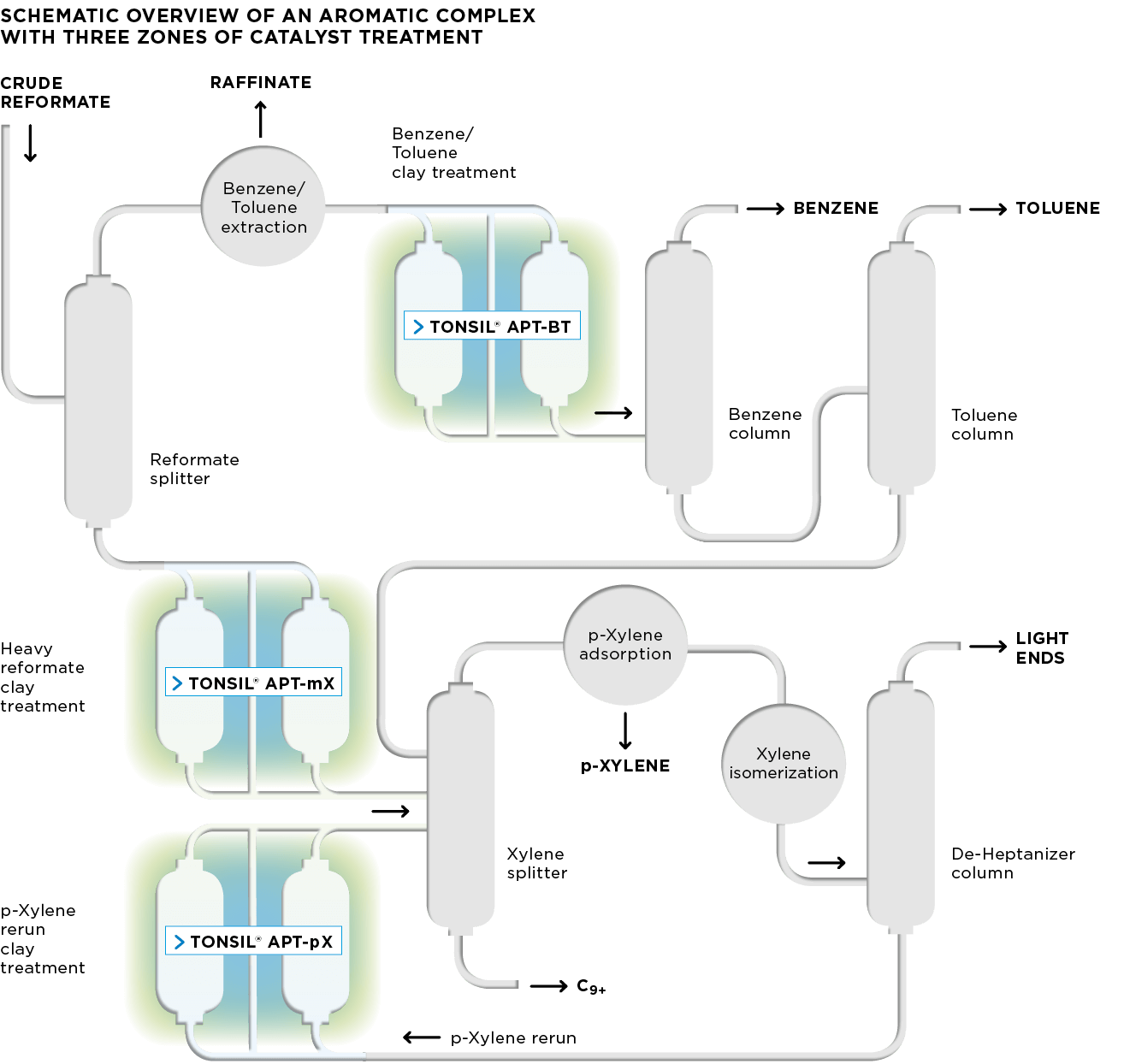

Aromatic compounds are produced in a fully integrated process with the intent of producing benzene, toluene and xylene (BTX). In the reformate splitter the feed stream is separated into two streams. For each application, Clariant offers a specialized product to increase yield, decrease by-products and prolong cycle length of downstream catalytic systems. Two of the well established designs for the Aromatic Complex are the Axens and the UOP designs. Both can use Tonsil™ catalysts.

Challenge: Manufacture aromatics with the highest possible purity

The challenges of the aromatic complex are:

- Obtain pure aromatics, particularly benzene and p-xylene

- Olefin removal in the minimum number of steps

- Need to keep the process running as long as possible to avoid extra costs incurred if the catalyst has to be changed

- Find suitable clay catalysts for special challenges of each application

- To remove impurities in the feed like organic nitrogen to enable a long catalyst cycle life

Solution:

Clariant’s TONSIL™ APT

removes undesired impurities and

olefins easily in aromatic streams

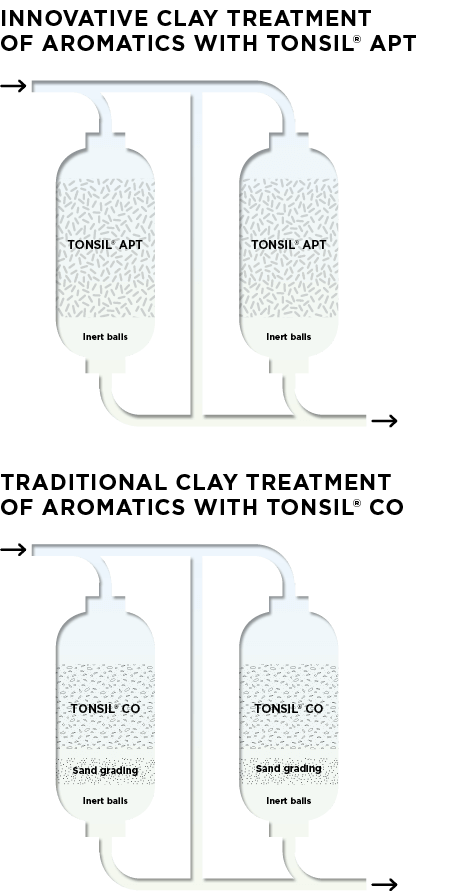

Tonsil™ APT are new types of catalysts which look different and show a better performance offering a multitude of advantages:

- Less complex loading (no sand required)

- Less pressure drop

- Less dust during loading

- Higher activity of catalyst

- Larger catalyst volume

Tonsil™ APT-mX

for heavy reformate stream

Tonsil™ APT-BT

removes olefins from benzene/toluene stream

Tonsil™ APT-pX

removes olefin from para-xylene rerun

Tonsil™ APT-N

removes organic nitrogen impurities

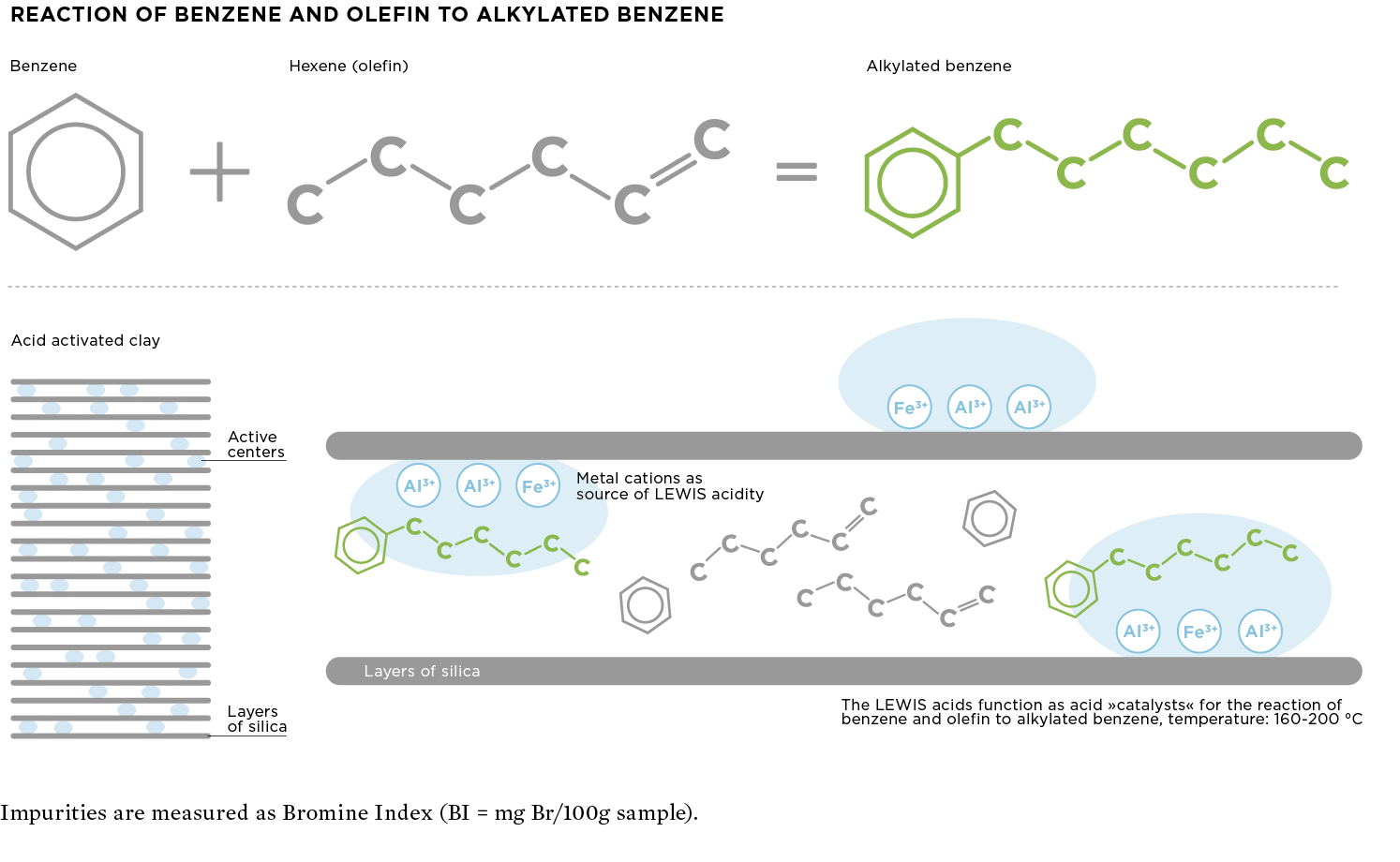

Olefin removal – Mode of function

The goal of this process is to manufacture pure aromatics. Tonsil™ APT-mX removes olefins from the heavy reformate stream, by acid catalyzed alkylation of benzene/toluene, to give products with a higher boiling point which can easily be removed later in the process. With the Bromine test olefins in the BT stream can be detected by color.

Benefits: BTX purification made easier with an array of supporting features

TONSIL™ APT series catalysts have their basis on the expertise which was gained with the TONSIL™ CO series. Tonsil™ catalysts contain less side reaction active sites, have high surface area and superior pore properties. Those properties ensure the long cycle time of Tonsil™ catalysts, thus reduce the number of change outs and operation costs, increase the operation efficiency and reduce energy consumption. Due to the larger loading volume and the higher bulk density of the Tonsil™ APT catalysts, the lifetime of any Tonsil™ APT is up to 15% longer than the comparable Tonsil™ CO catalyst.

Longer Cycle life

Easier Loading

Larger loading volume

Higher activity

Reduced energy

consumption

Reduced

OPEX Costs

Worldwide availability and service: Always close to you, Offering quick service and solutions