Volatile Organic Compound Adsorbents for Packaging and Cargo Shipments

CONTROL POTENTIAL HAZARDS OF VOCs OFF-GASSING FROM MANUFACTURED PRODUCTS

Volatile Organic Compounds (VOCs) can occur when chemicals in plastics, solvents, or adhesives “off-gas” during or after manufacturing of a variety of common products, including:

- Shoes, sandals, and textiles

- Plastic packaging, films, wraps, liners, and curtains

- Foam pillows, furniture, and “memory foam” mattresses

- Foam insulating materials

- Carpeting

- Paints

- Construction materials

- Plastic toys

- Rubber products

Many industries use raw materials known to emit harmful VOCs in manufacturing processes. Despite ongoing efforts to limit the use of these materials in manufactured products, controlling and minimizing the hazard of VOCs to people and the environment remains a serious challenge.

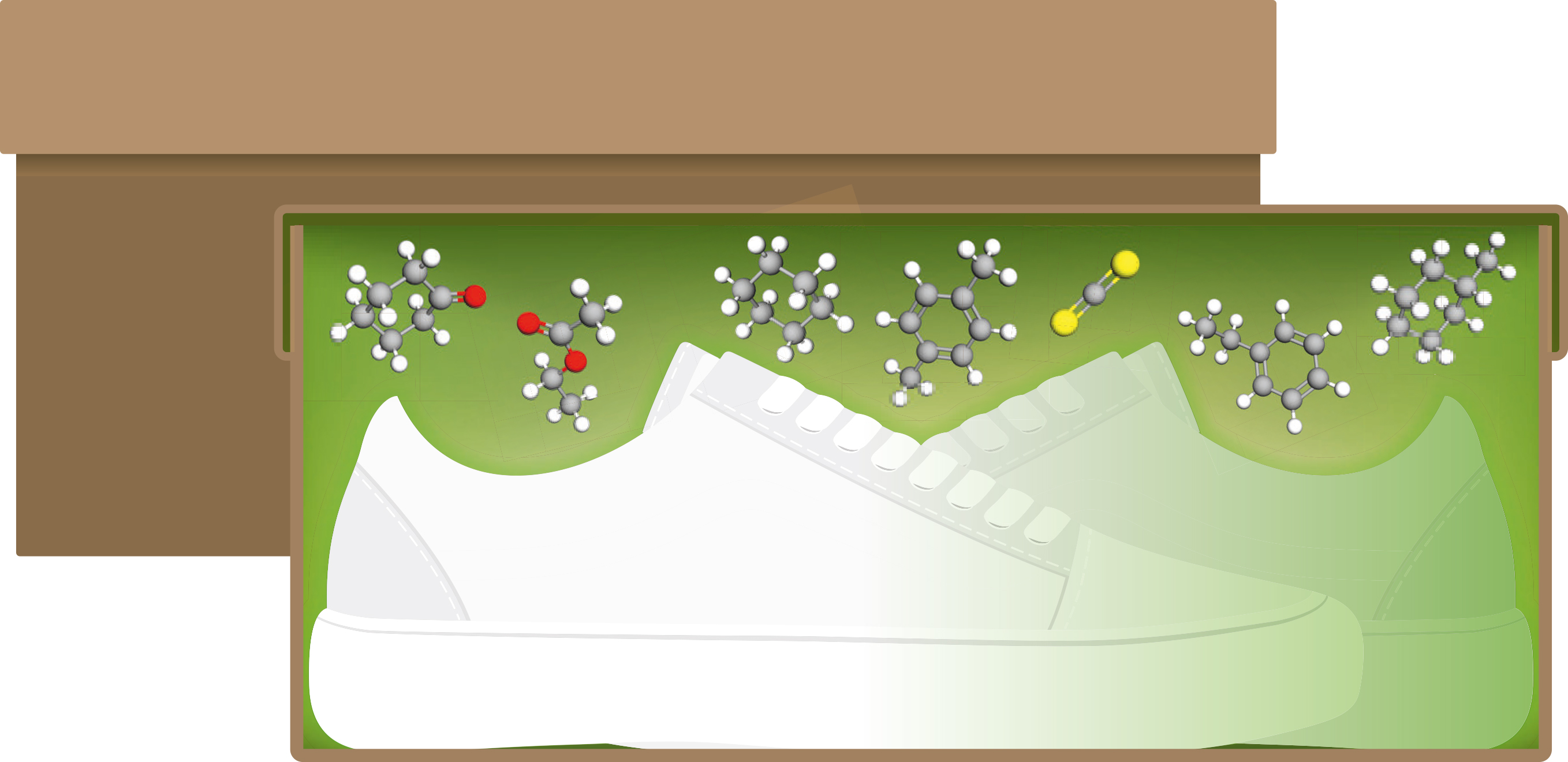

Here’s why: VOCs can accumulate every time that manufactured goods are stored in enclosed areas. These include everything from individual shrink-wrapped packages and shoe boxes to large product shipments in trailers or shipping containers. When these packages or containers are opened, the sudden release of accumulated VOCs can, if inhaled, pose serious health risks to people.

Illustration of VOCs off-gassing inside a shoe box

Source: Clariant

For manufacturers and shippers who rely on timely inspection, acceptance, and unloading of large containerized cargoes, even the potential for unacceptable VOCs in a shipment can cause unexpected delays and higher costs. Cargo inspection and unloading personnel may hesitate to enter the container without respirators, or decide that chemical detection equipment must be used to test the air. They might also decide to ventilate the container for up to several days – opening its contents to the risk of weather damage, loss or theft – until the VOC threat is eliminated.

Illustration of VOCs off-gassing inside a shipping container

Source: Clariant

VOCs can also be problematic and costly in product distribution to merchants or customers. Boxed or palletized loads of product with unacceptable VOCs or unpleasant odors – possibly associated with the presence of VOCs – may require additional handling or “airing out” by merchants before they can be displayed for sale or shipped to customers. Concerned customers may also reject and return products that, once opened, are found to be unappealing or thought to be potentially hazardous.

So, what can manufacturers and shippers do to eliminate VOCs?

Fortunately, there are solutions available to help control and eliminate the accumulation of VOCs in manufactured products. For example, DESVOCANT™ is a new line of VOC adsorbing products from Clariant Cargo & Device Protection. Available in a variety of sizes – sachets, bags, or large bags – for placement in everything from small product packages to fully-loaded shipping containers, DESVOCANT™ adsorbents help to eliminate many common VOCs. Best of all, they offer this protection using a naturally-occurring, sustainably mined, non-toxic, granulated, dried clay mineral, with a unique structure, found in the Earth’s crust.

Source: Clariant

After drying and granulation, clay mineral used in DESVOCANT adsorbs a wide range of VOCs that are associated with chemicals and polymers, for example:

- aromatic compounds: benzene, toluene, xylene

- aldehydes and ketones: formaldehyde, acetaldehyde, ethylbutylketone, acetophenone

- halogenated hydrocarbons: 1,2-dichloroethane, carbon tetrachloride, chlorobenzene, 1,1,2,2,-tetrachloroethane

- Alcohols: methanol, ethyl alcohol, isopropyl alcohol

- Others: esters/ethers, nitrogen compounds, sulphur compounds

Free-flowing granules of this adsorbent clay are contained in packages made with air-permeable materials. The free flow of air through the package exposes VOCs in the air to contact with the granules, whose surface attracts and binds VOCs through adsorption. This natural process greatly reduces the VOCs from the air, trapping them – with their associated odors – within the adsorbent package. The clay granules in DESVOCANT adsorbents are non-dusting and fully contained in product packaging, so they pose no risk of dusting or staining light-colored goods like shoes, carpets, or foam pillows and mattresses.

DESVOCANT adsorbents can be blended and packaged with other materials to meet a wide range of application requirements. Experts from Clariant Cargo & Device Protection work closely with customers to evaluate each application, calculate VOC adsorption and cargo-protection requirements, and recommend the correct product solution and dosage.

Illustrations of VOCs adsorbed by DESVOCANT

Source: Clariant