Shipping Delays, Port Congestion May Increase the Risk of Moisture Damage to Container Ship Cargoes

CONTAINER DRI® II DESICCANTS HELP PREVENT CONDENSATION INSIDE SHIPPING CONTAINER DURING TRANSPORT, EVEN WHEN CARGO IS IDLED

Recovering from the enormous global production and trade disruptions caused by the COVID-19 pandemic is proving difficult for shippers, ports, manufacturers, farmers, and consumers alike. The pandemic caused a surge in global demand, fed by consumers staying at home, and led to huge inventory drawdowns even as global suppliers cut production and shipments due to lockdowns.

And now, as shipping companies strive to maximize available container shipping capacity, cope with regional shortages of available containers, and help customers replenish inventories and reestablish market stability, port congestion has emerged as another, major problem.

Huge volumes of global trade typically flow through about 20 major container ports, primarily in Asia, Northern Europe, and the West Coast of the United States, that offer high container handling capacity and abundant links to intermodal train and truck transport. However, recent record shipping volumes are currently overwhelming their capacity. Consequently, instead of sailing in, berthing, and unloading in a day or two – typical for “normal” times – container vessels are queuing up and waiting up to two weeks for a chance to unload, take on new cargo, and continue their routes.

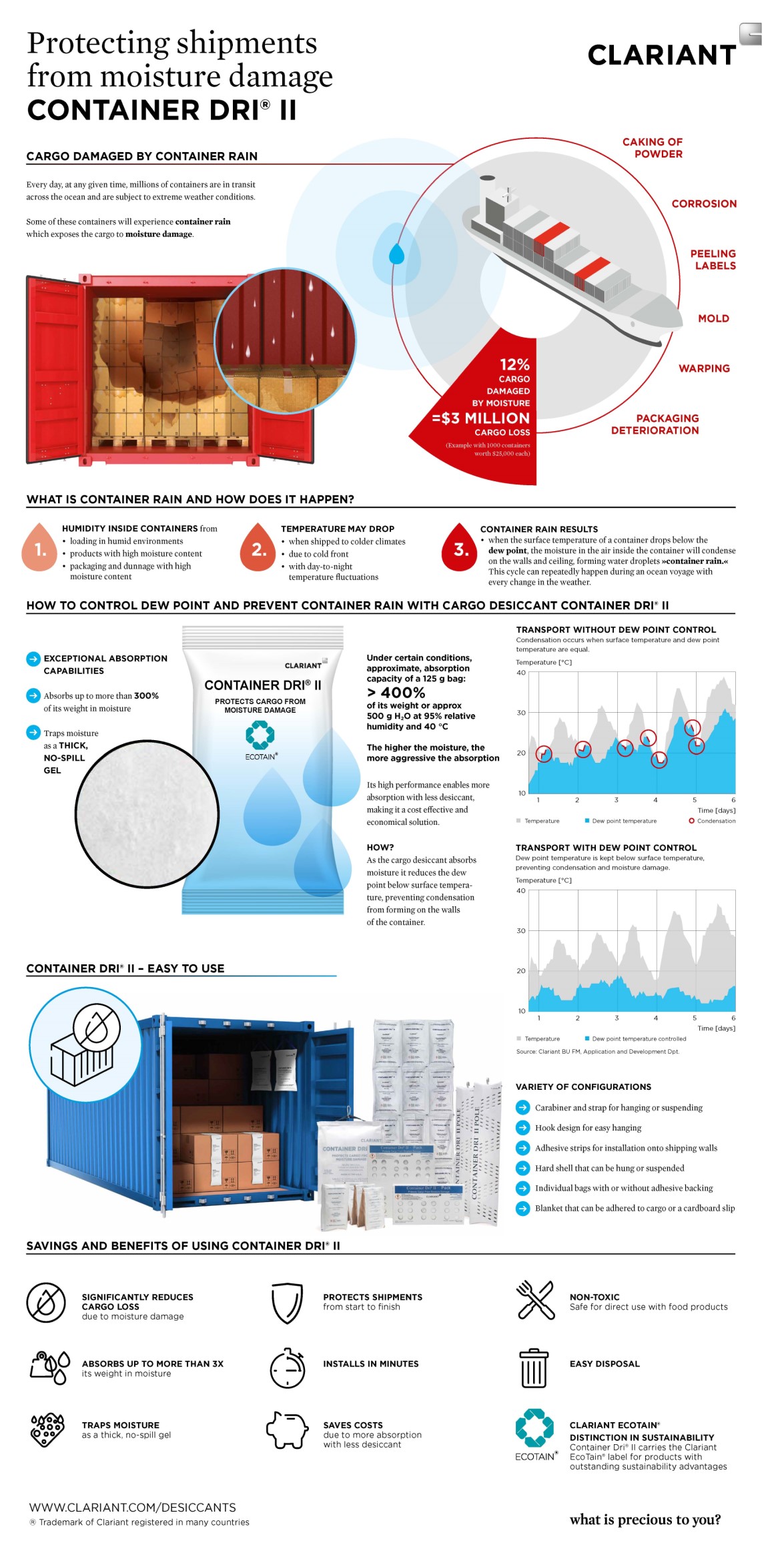

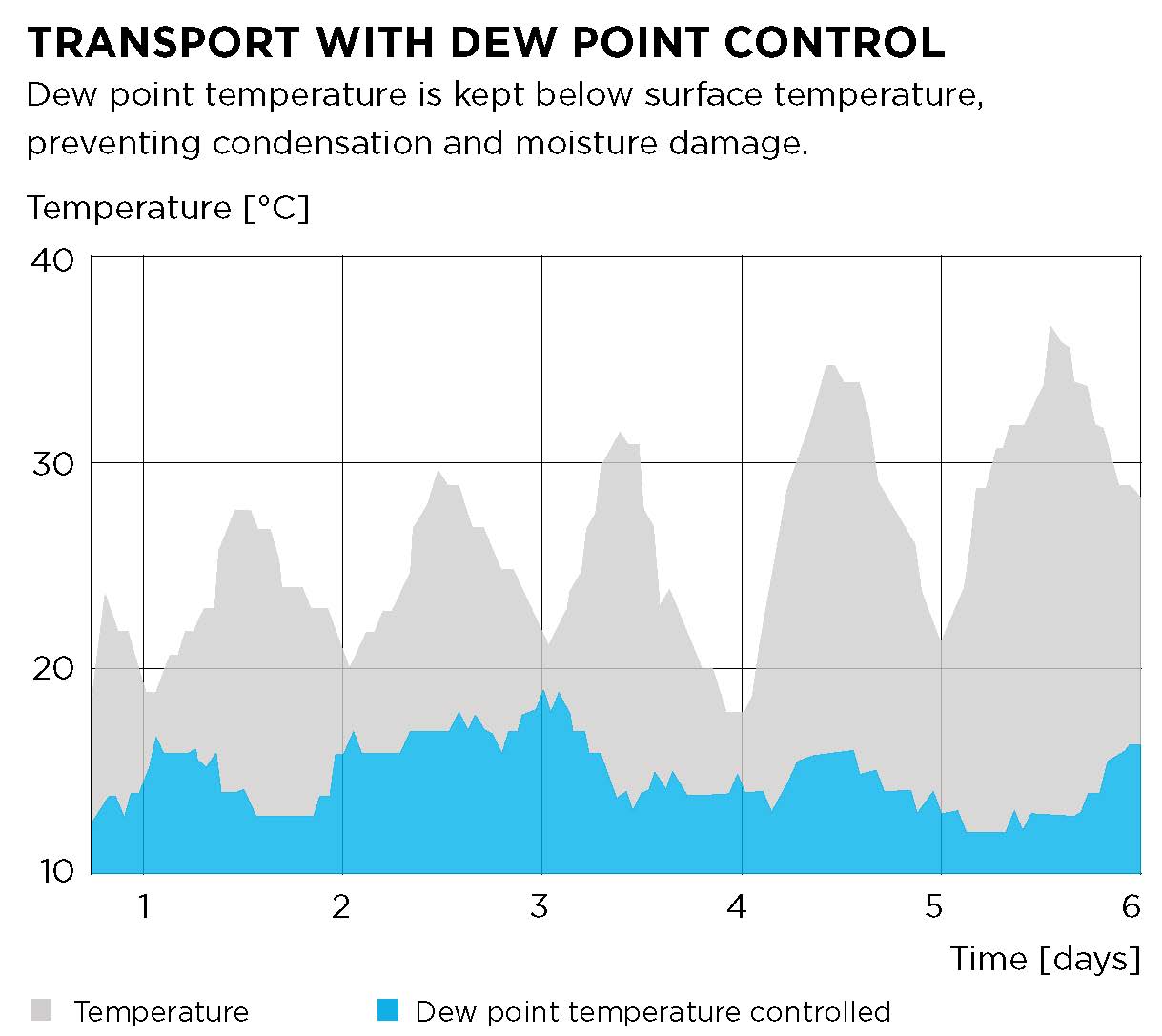

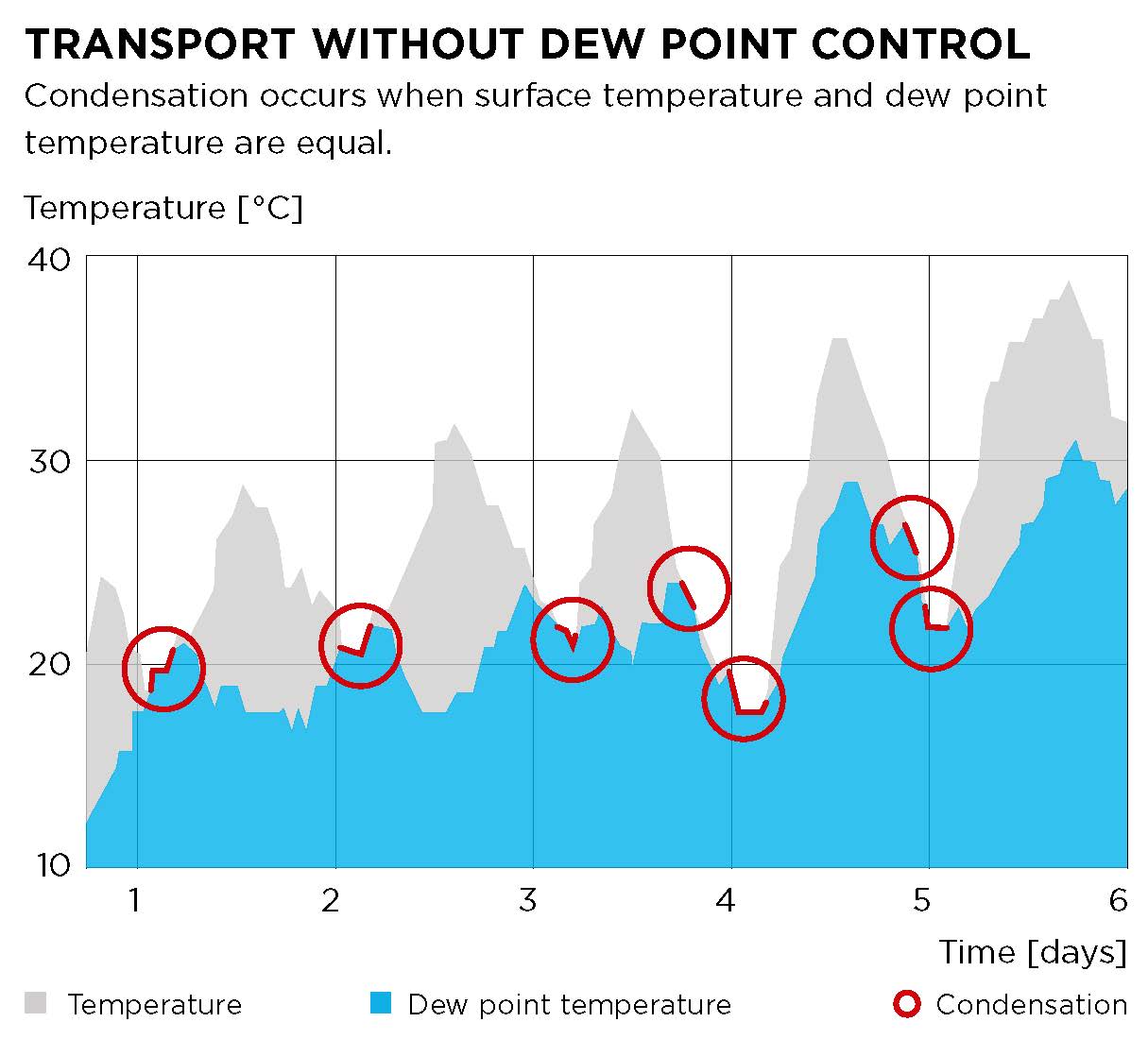

With shipping prices spiking higher, port congestion common and shipping/delivery schedules uncertain, it is more important than ever to ensure that containerized cargoes have long-duration protection against moisture. Moisture can accumulate to damaging levels at virtually any time during land and sea transport over thousands of miles, across climates and through every type of weather. All that is needed is a rapid temperature drop of 4.4 to 5.5° C (8 to 10° F) in the surface temperature of the shipping container. At that point, residual humidity held in ambient air, goods or commodities, packaging materials, pallets, and even wooden container floors can release and condense rapidly on the container’s ceiling and walls into water droplets commonly referred to as “container rain.”

Container rain can occur in any enclosed space, from the inside of a product package to the microclimate within a 20- or 40-foot shipping container. And when it does, any moisture-sensitive goods – raw agricultural commodities (grains, nuts, coffee beans, cocoa beans), metal products, fabric and leather goods, consumer electronics – are vulnerable to damage. Relative humidity levels as low as 40% can trigger surface rust on metals, while higher humidity levels (60-70% or greater) support the growth of damaging molds, mildews, or other microorganisms. Repeated warm-cool weather cycles only intensify the risk of damage, exposing cargo and packaging to high humidity and droplet condensation again and again.

Source: Clariant

So, what’s the solution? Global trade experts recommend cargo moisture protection that lasts for the duration of the journey, from container loading and sealing to the point of delivery at the customer location.

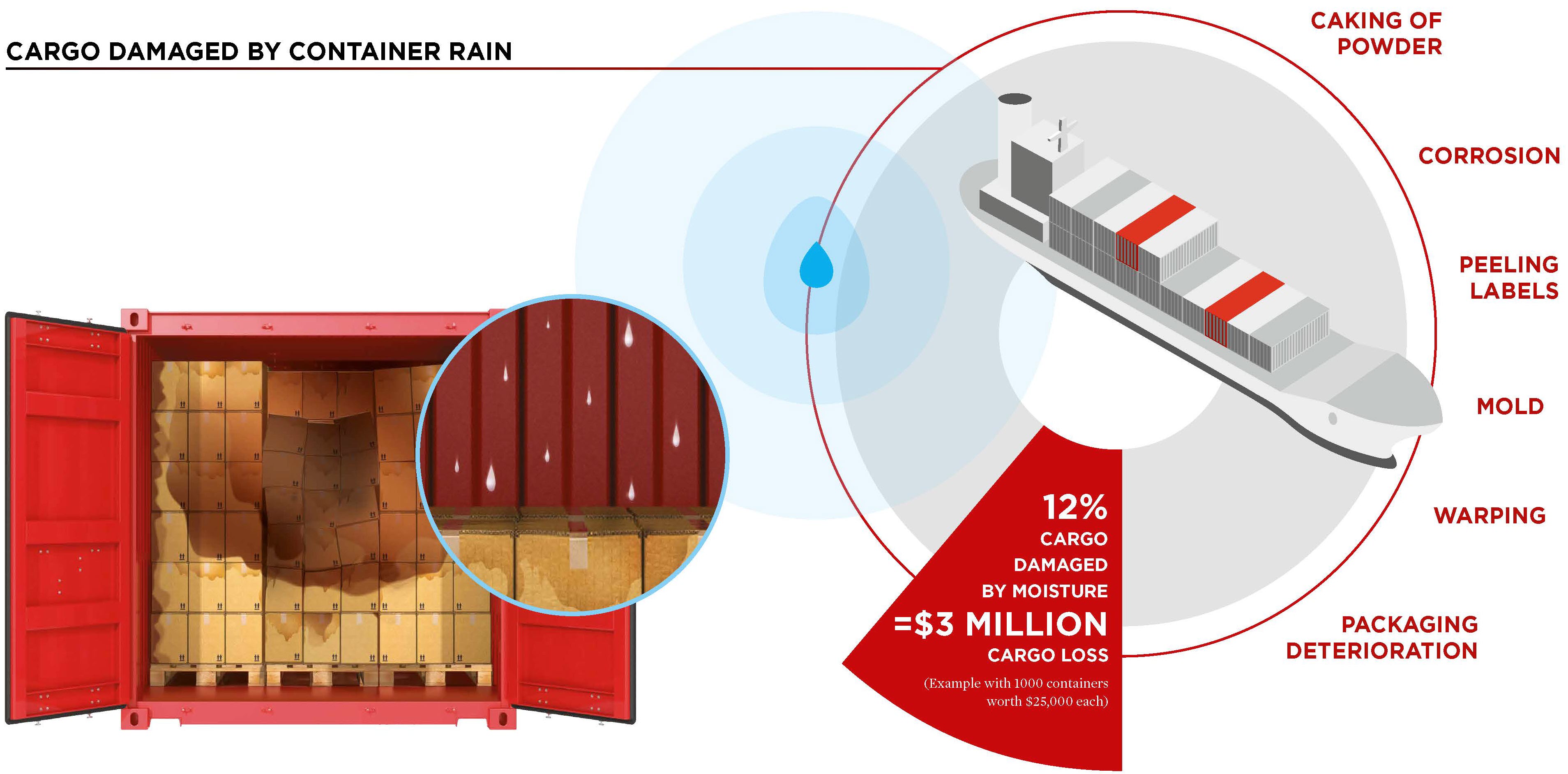

Protect container-sized shipments with high-performance desiccants

Container Dri® II cargo desiccant is specially developed to prevent moisture damage to large, containerized cargoes. When used in properly sealed shipping containers in the form of desiccant bags, strips, poles, or blankets, it absorbs excess moisture and traps it in a thick, no-spill gel. Despite even large shifts in temperature, the continuous drying action of Container Dri II desiccants helps to maintain a low relative humidity, keeping it well below the dew-point temperature at which moisture would otherwise condense and form container rain.

When used in sealed shipping containers in the form of desiccant bags, strips, poles, or blankets, Container Dri® II absorbs excess moisture and traps it in a thick, no-spill gel.

Source: Clariant

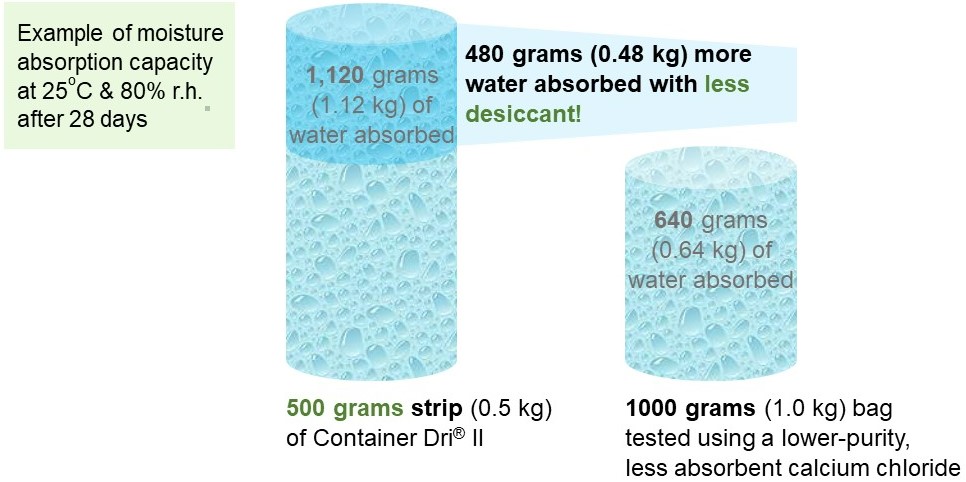

Made from a blend of high-purity calcium chloride and a special gelling agent, Container Dri II provides excellent moisture protection because it absorbs exceptional amounts of moisture, pound for pound, unlike when a lower-purity calcium chloride was tested. Internal tests show that it can absorb an outstanding quantity of 300% or more of its own weight in water, and that a smaller (500 g) bag of Container Dri II can absorb more than a larger (1,000 g) test bag made of a lower-purity calcium-chloride. Given the uncertainty of shipping and delivery delays, Container Dri II provides a comforting level of moisture protection.

Less is more example – Container Dri® II

Internal tests results show a 500 gram strip (.5 kg) of Container Dri II absorbed 75% more than a 1,000 gram (1 kg) bag tested using a lower-purity, less absorbent calcium chloride.

Source: Clariant BU FM, Application and Development Dpt

In addition, Container Dri II cargo desiccant:

- Works gradually and continuously, absorbing more moisture when humidity levels are higher and less when they are lower, making it an excellent choice for large, long-duration, or idled shipments

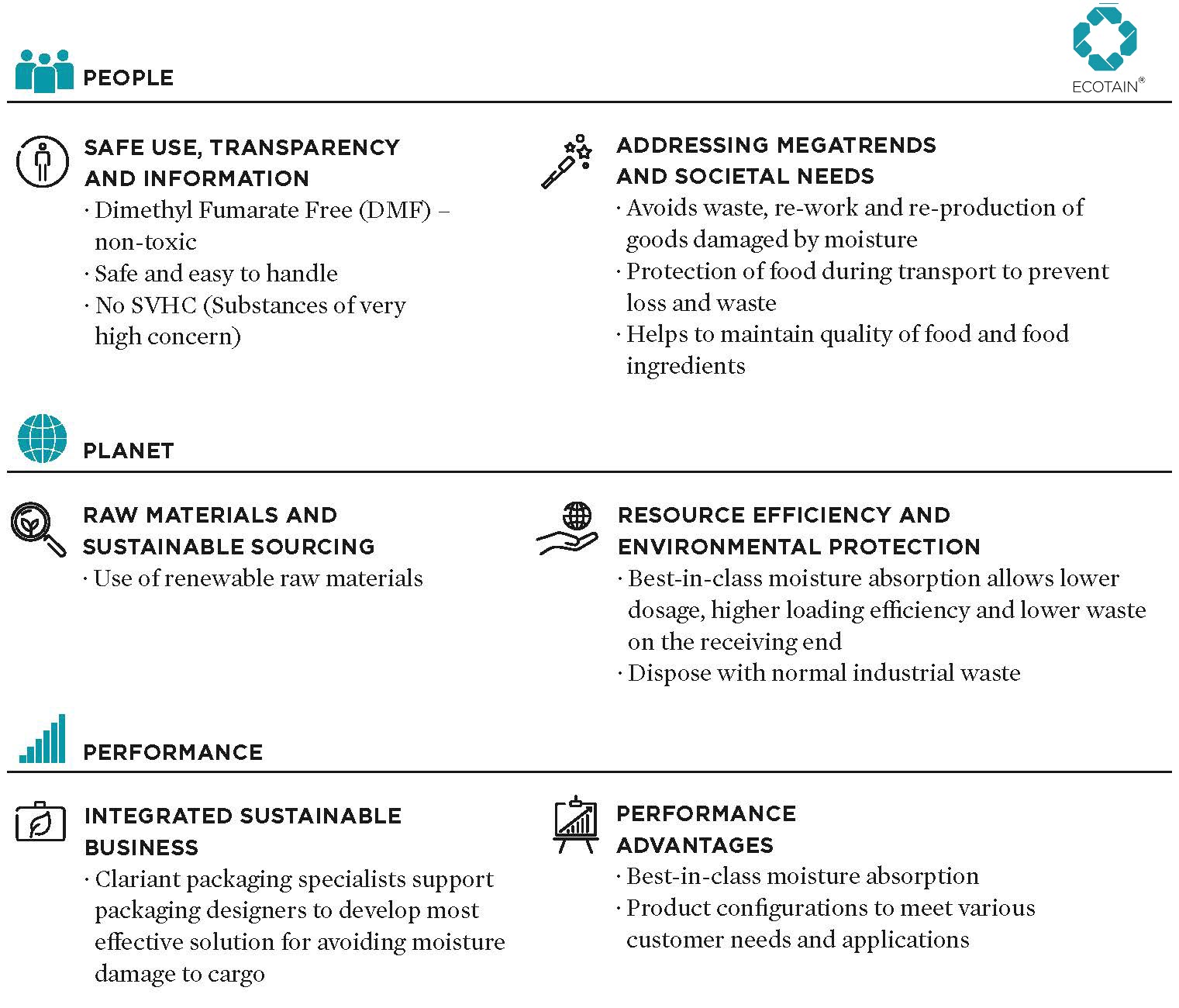

- Is non-toxic, safe for use with food products, free of Dimethyl Fumarate and Substances of Very High Concern (SVHCs per EU REACH Regulations) and easy to handle and dispose of in normal trash.

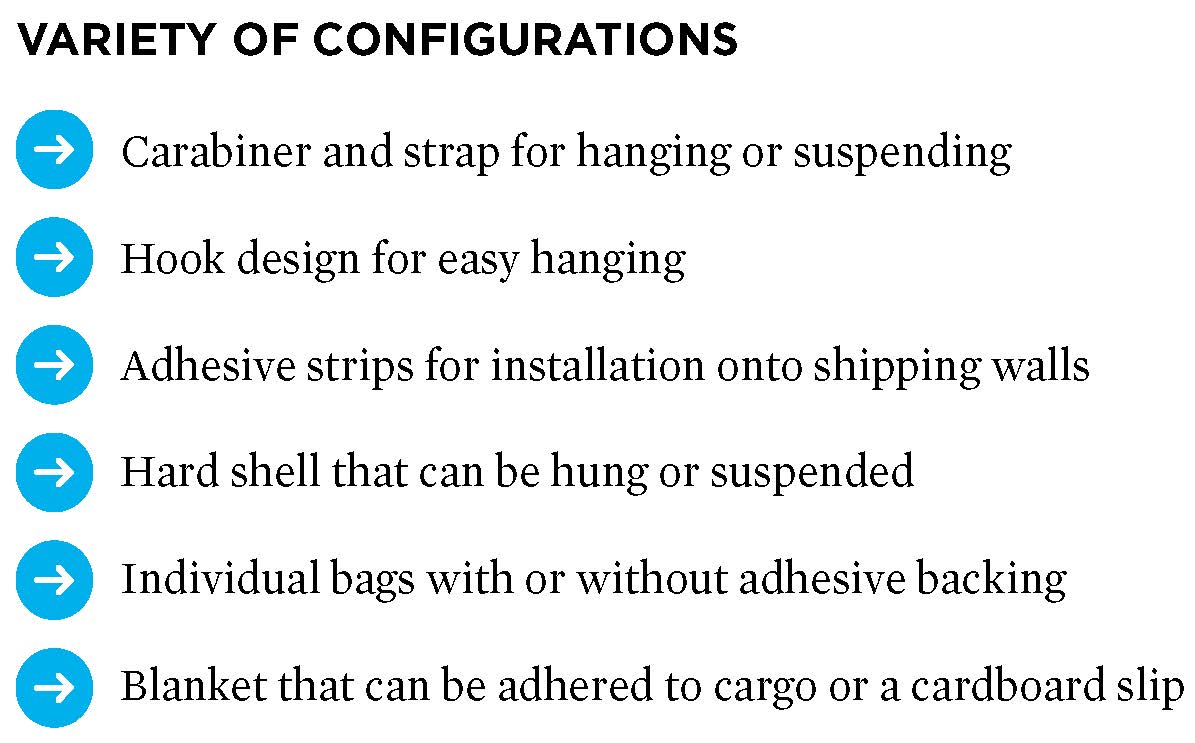

- Is available in a variety of package configurations for simple installation and use in cargo containers.

- Is recognized with Clariant’s EcoTain® label due to its outstanding sustainability advantages.

Container Dri II Is available in a variety of package configurations for simple installation and use in cargo containers.

Source: Clariant

Container Dri II is recognized with Clariant’s EcoTain® label due to its outstanding sustainability advantages.

Container Dri Source: Clariant

For companies that need to protect incoming goods while in storage or outbound shipments until transport becomes available, Clariant Cargo & Device Protection offers a range of other desiccant products suited to protecting individual, sealed product packages. These include Desi Pak® desiccant bags and packets, a line of sustainable desiccants made with naturally-occurring, non-toxic bentonite clay, Sorb-It® silica gel desiccants, and Tri-Sorb molecular sieve desiccants.

Call us or contact us above. We have experts with decades of experience ready to help determine which cargo desiccant is best for your shipping needs.