Our halogen-free Exolit™ OP flame retardants -

safe and sustainable fire safety for the materials of our times

Experience a new OP-timum in modern fire protection

From electrical and electronic components to the foams and fabrics of modern mobility, work and leisure: Our organophosphorus Exolit™ OP flame retardants give non-halogenated fire resistance to polymer materials that combines high performance with exceptional sustainability.

Tailored solutions for thermoplastics – plus reactive and green OP-tions

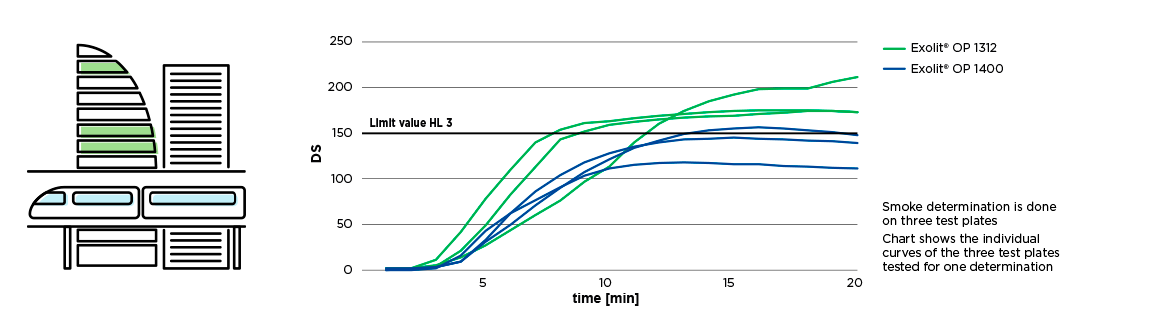

Our Exolit™ OP product line comprises halogen-free phosphorus containing polyols as well as organic phosphinates. The phosphinates and synergistic blends of our Exolit™ OP line can provide fire resistance to a wide range of polymers used in E&E, transportation, fibers and other segments without affecting the high performance of polyamides and polyesters in connectors, switches and other electrical parts, and impart fine-powdered safety to printed electronics and PET fibers. Our phosphorus-based polyols (Exolit™ OP 552 and 560) are reactive solutions for polyurethane foams that become chemically bound to the foam and do not emit the flame retardant or leach out.

Several grades are available as earth-friendly »Terra« versions based on renewable carbon. These drop-in alternatives provide the same OP-timum performance – and go on doing so even after multiple rounds of recycling.

Find out more about our Exolit™ OP solutions

The one-two-three of better fire safety,

key benefits of our EXOLIT™ OP line

1.Exolit ™ OP phosphinates are halogen-free, non-toxic solutions produced with 100% green electricity.

2.Glass fiber-reinforced PA6 and PA66 composites containing Exolit™ OP can keep UL 94 V-0 rating even after multiple rounds of recycling.

3.Renewable carbon-based versions without concessions to quality and performance that can be »dropped in« without further tests or approvals.

Are our OP products a good choice for flame-retarding modern electronics? Eason Lee definitely thinks so

»Our material for flexible printed circuit board applications are used in light, thin, powerful electronics – like those supporting 5G. To protect these boards against fire, we use the Exolit OP™ 9xx series, which we highly value for its performance, options in particle size, flame resistancy and consistent quality.«

Eason Lee

Assistant Manager, R&D Center, Taiflex Scientific Co., Ltd.

OP-timal numbers for thin and sustainable plastics

mmLowest thickness

that can achieve UL 94 V-0

rating with Exolit™ OP

GreenScreen® rating

best-in-class Benchmark 3

result for Exolit™ OP line

> %Less carbon

in the footprint of our

Exolit™ OP Terra

products