Ink and Toner Additives

Add to the appeal of printed products

For printing results that pass the tests

WITH FLYING COLORS

Despite the ubiquity of digital texts and images, being able to efficiently reproduce these on paper and other substrates still has enormous relevance in today’s world – be it in publishing, packaging and advertising, or when making simple printouts at the office.

Clariant’s high-performing wax additives for printing inks and toners help formulators to enhance the appeal, longevity and commercial success of their products. Our micronized waxes improve gloss control, rub resistance and anti-blocking behavior in printing inks, and are suited for water- and solvent-based as well as UV-curable systems. With their beneficial effects on release and efficiency, our additives can also substantially add to the performance of laser printer toners and similar products.

Ink waxes and toner additives for a wide spectrum of platforms and needs

Clariant is one of the world’s leading providers of high-quality wax solutions. Through intense collaboration and close relationships, we support our ink and toner customers in creating value-adding offerings for a wide range of applications.

Our ink and toner additives have been developed to suit the full panoply of common printing techniques, from offset, gravure and flexography, to overprint varnishes (OPVs), printing on packaging, laser printing and many more. With highly effective solutions and tailored polymer designs, we enhance crucial properties such as coefficient of friction and scratch resistance, enabling considerable benefits in terms of performance, efficiency and costs.

PTFE free additives for printing inks

PTFE/wax blends are used for their strong rub resistance and slip effect, but rising concerns about their regulatory and sustainability profile increases the need for PTFE free alternatives.

Traditional PTFE will need to be replaced with low-PFOA containing PTFE or PTFE free alternatives using new technologies. At Clariant, we know that modern printing demands flexible, high-quality solutions, which is why we have developed PTFE free alternatives and sustainable technologies for synthetic waxes that play a crucial role for surface variations within inks and coatings, such as scratch resistance, modification of slip properties, matting effects and more. These new wax technologies are based on renewable and sustainable raw materials, with a continued focus on performance and cost optimization.

The uncertainty around the details of regulatory changes that are to come can make it challenging for businesses to address these issues. With an advanced, forward-looking portfolio of bio-based, sustainable additives for printing inks, paints and coatings, Clariant is taking a proactive, pro-safety and pro-environment approach to help customers navigate this uncertain and fast-changing landscape.

See how we add value

IN THE SEGMENTS WE SERVE

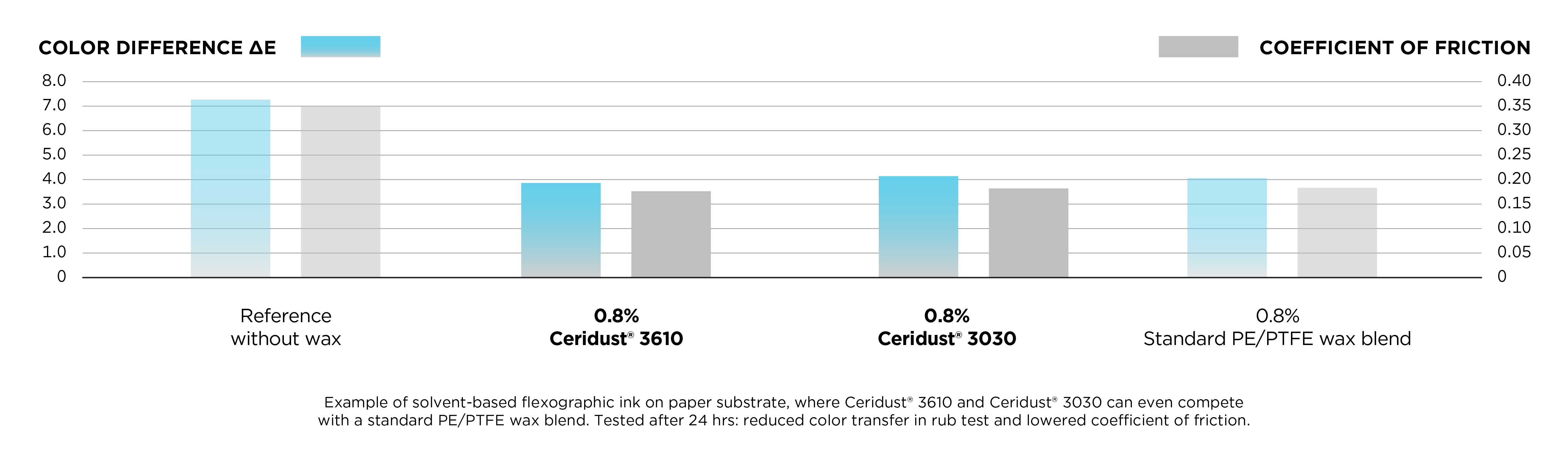

PTFE-free improvement of flexo inks

WITH OUR METALLOCENE-BASED PE WAXES

Outstanding rub resistance of printing inks

Three good reasons for choosing Clariant

KEY BENEFITS OF OUR WAX SOLUTIONS

1.High-performing PTFE-free solutions for improving rub resistance and for protecting the quality and visual appeal of printed materials

2.Additives capable of enhancing the anti-blocking behavior of printed products and preventing the adhesion of surfaces

3.Waxes allowing better gloss control and enabling effects ranging from strong matting to intense brightening of printed results

Benefits and flexibility

YOU CAN COUNT ON

up to %Less additive needed

to achieve the same performance and results

up to %Renewable content

distinguishing our sustainable wax solutions

40-°CMelting point range

to choose from in our broad wax portfolio