Safewing™ aircraft Deicing

Safewing™: Effective solution against snow and ice

Even in extreme winter conditions, runways need to be clear and the surfaces of aircraft must be free from ice and snow before take-off.

This is why Clariant has developed Deicing / Anti-Icing Fluids, which fulfill all international requirements. We apply exacting standards to the quality and reliability of these products. In attaining these standards, environmental protection is given equal priority.

Clariant has wide-ranging expertise in research, development and environmental protection. With over 40 years of deicing industry experience, our aircraft deicing products ensure the safety that people depend on.

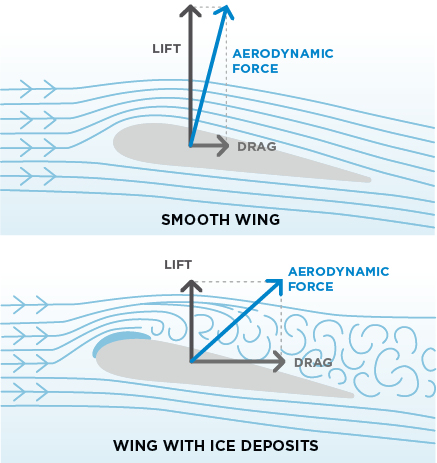

For safety reasons aircraft wings have to be free of ice and snow

Worldwide, more than 41 million airplanes with over 4 billion passengers take off in the course of a year. During the winter months, ice and snow on the wings can interfere with lift, which can lead to crashes. To prevent that, special fluids are used to deice planes and protect them from reicing before take-off. They are colored differently to facilitate telling them apart and see whether they have been spread evenly.

Challenge

Environmental impact of Deicing and Anti-Icing-Fluids

Deicing and Anti-Icing Fluids are based on either ethylene or propylene glycol. While glycols are easily biodegradable, the degradation process uses up large amounts of oxygen thus potentially harms aquatic organisms. Flight cancellations due to lack of Deicing Fluid are another, completely different challenge due to insufficient stocking and/or logistics.

Solution

SAFEWING™ DEICING AND ANTI-ICING

FLUIDS – SUPERIOR SUSTAINABILITY

AND RELIABLE SUPPLY

Clariant is one of the largest manufacturers of Deicing and Anti-Icing Fluids in the world. With the Safewing™ portfolio Clariant offers different kinds of Deicing fluids (Type I) and Anti-Icing Fluids (Type II and IV). The Deicing Fluids are used to remove ice and snow from planes by spraying the heated fluid with high pressure onto the surfaces. Type II and Type IV Anti-Icing Fluids are used to coat aircraft parts with a viscous layer that protects against the new formation of ice, greatly extending the time window for the take-off of the aircraft. Before the aircraft leaves the ground, their viscosity drops significantly due to various mechanical forces, thus flowing off.

All Clariant Deicing and Anti-Icing Fluids have a superior environmental profile thanks to their fully biodegradable additive packages and low surfactant content. Furthermore, Clariant has developed a special on-site recycling program that ensures that up to 70 percent of the glycol can be re-used in the production of Deicing Fluids. Due to its global presence, Clariant has the logistic capability to provide regional airports with very short lead times.

Benefits

Effective against snow and ice with a superior environmental profile – delivered quickly and reliably all over the world

PROVEN

QUALITY

Effective Deicing and long holdover times have helped to make air traffic safe for decades

RELIABLE

SUPPLY

Short delivery times and a tested service provide maximum planning security

SUPERIOR

SUSTAINABILITY

Elimination and reduction of problematic ingredients plus highly effective recycling concepts

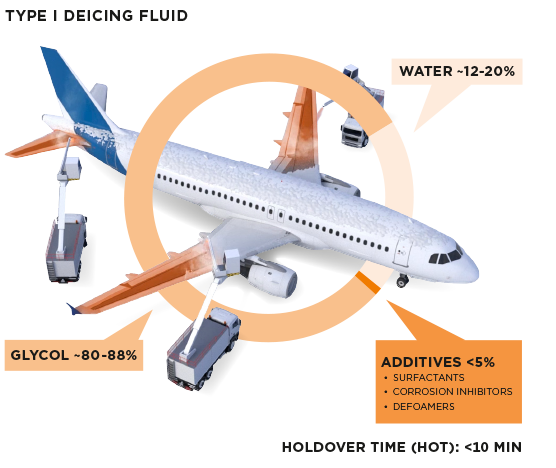

Type I

Type I Fluids are water/glycol mixtures with a glycol content of at least 80%, which contain a corrosion inhibition package. These fluids have been used for many years to remove ice, snow and frost (Deicing). They offer only very limited protection against further icing due to freezing precipitation.

Type I Fluids can be used in “single fluid” Deicing / Anti-Icing operations, but are usually used in conjunction with Type II, or IV as part of a two-step Deicing / Anti-Icing procedure.

Specification: AMS 1424, ISO 11075

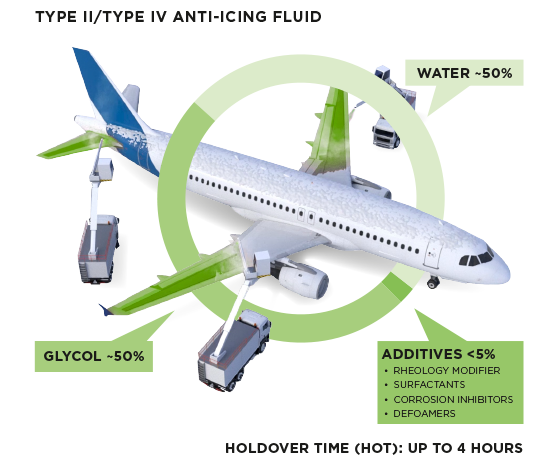

Type II

Type II Fluids contain at least 50% of glycol and a corrosion inhibition package. Furthermore they contain pseudoplastic thickener system which additionally protects the aircraft against Re-freezing (Anti-Icing) due to its film-forming properties.

Type II Fluids can be used in “single fluid” Deicing / Anti-Icing operations, or can be used in conjunction with Type I as part of a two-step Deicing / Anti-Icing procedure.

Specifications: AMS 1428, ISO 11078

Type IV

Type IV Fluids contain at least 50% of glycol and a corrosion inhibition package. Furthermore they contain pseudoplastic thickener system which additionally protects the aircraft against Re-freezing (Anti-Icing) due to its film-forming properties.

Type IV Fluids offer longer holdover than Type II Fluids.

Type IV Fluids can be used in “single fluid” Deicing / Anti-Icing operations, or can be used in conjunction with Type I as part of a two-step Deicing / Anti-Icing procedure.

Specifications: AMS 1428, ISO 11078