Catalysts for green ammonia production and ammonia cracking

Transporting hydrogen through chemical conversion to ammonia is gaining considerable attention as it is expected to be the most cost-competitive solution at the very large scale required. In this method, hydrogen is first converted to ammonia (NH3) for storage and transportation, and then at the point of use, ammonia is reconverted to hydrogen via cracking. As one of the leading catalyst providers in the ammonia-related new hydrogen economy, Clariant offers highly innovative catalysts for ammonia synthesis and its cracking.

Catalysts for green ammonia production and ammonia cracking

Transporting hydrogen through chemical conversion to ammonia is gaining considerable attention as it is expected to be the most cost-competitive solution at the very large scale required. In this method, hydrogen is first converted to ammonia (NH3) for storage and transportation, and then at the point of use, ammonia is reconverted to hydrogen via cracking. As one of the leading catalyst providers in the ammonia-related new hydrogen economy, Clariant offers highly innovative catalysts for ammonia synthesis and its cracking.

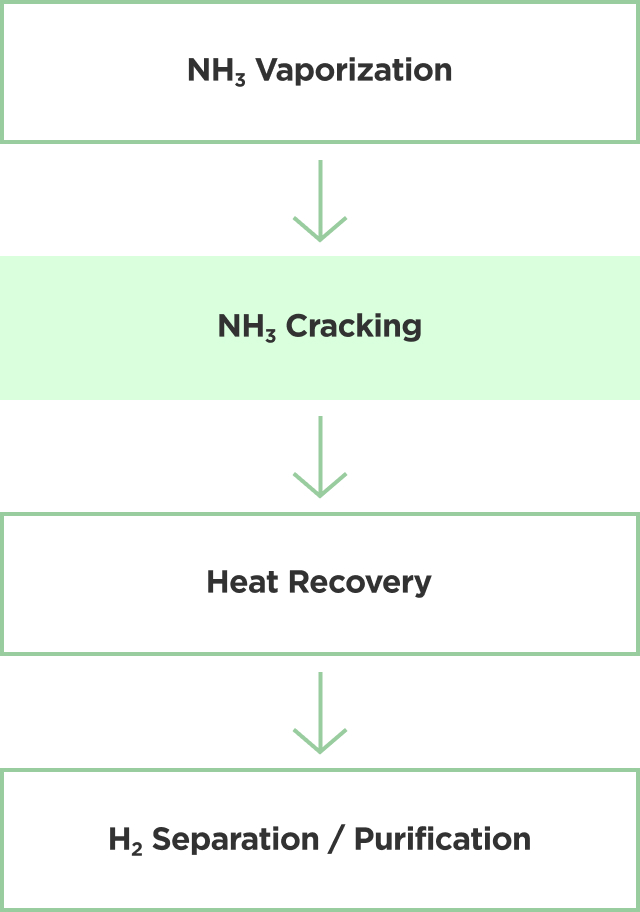

Process of ammonia cracking

Large-scale ammonia cracking

For large-scale processing of more than, e.g., 1,000 t/d of ammonia to feed hydrogen into the energy grid, major industrial plants are clearly favorable. These can be built to employ proven nickel catalysts like HyProGen 820, 821 and 830 DCARB to meet the needs of industrial consumers like municipalities or steel, cement, and chemical companies.

In most cases, these large plants will have two types of reactors to maximize the efficiency of the plant.

Small-scale ammonia cracking

Decentralized facilities are suitable for small-scale processing of several hundred kilos of ammonia per hour using ruthenium catalysts, for example, HyProGen 850 DCARB, resulting in high-purity hydrogen, e.g., for fuel cell applications. Ideal locations are near filling stations supplying hydrogen for vehicles.

The ammonia cracking process to reconvert ammonia to hydrogen can take place in centralized large-scale plants located near ports or in smaller decentralized facilities e.g., in urban areas. Centralized and decentralized ammonia cracking each have certain advantages, depending on the intended point of use.

Ammonia cracking process scheme and reactor types

Ammonia cracking process scheme and reactor types

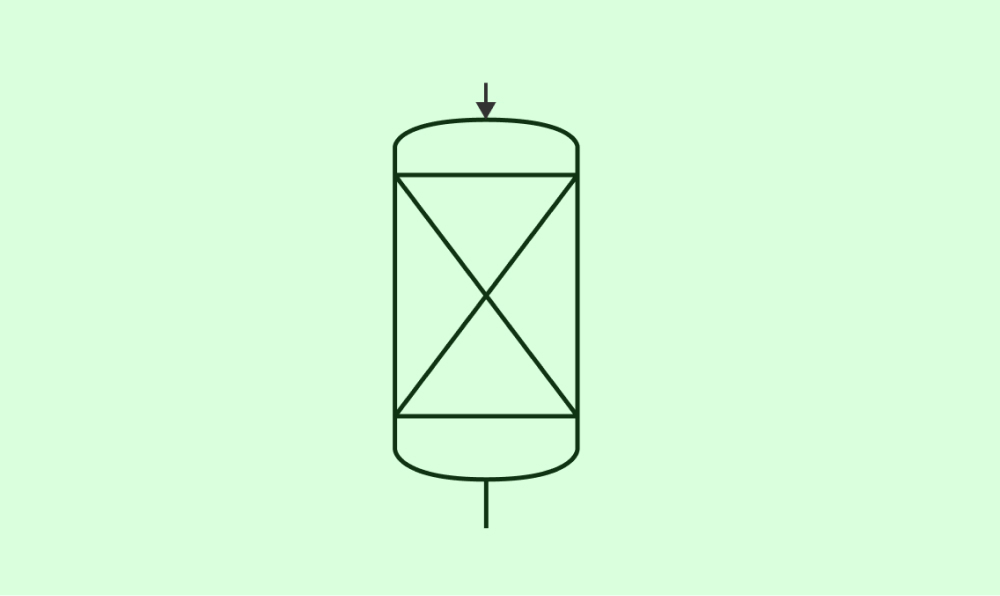

Adiabatic reactors

- Catalysts need high activity and can be smaller in size, and demands on mechanical stability are lower

- Full-particle catalysts with high active metal content

- Pressure 20–40 bar / up to 650 °C

Clariant catalysts for adiabatic reactors

HyProGen 820 DCARB: Novel recipe enhances thermal stability, enabling a higher inlet temperature of the adiabatic reactor

HyProGen 821 DCARB: Highly active Ni-based catalyst for low-T application, optimized for bottom layer of adiabatic reactor

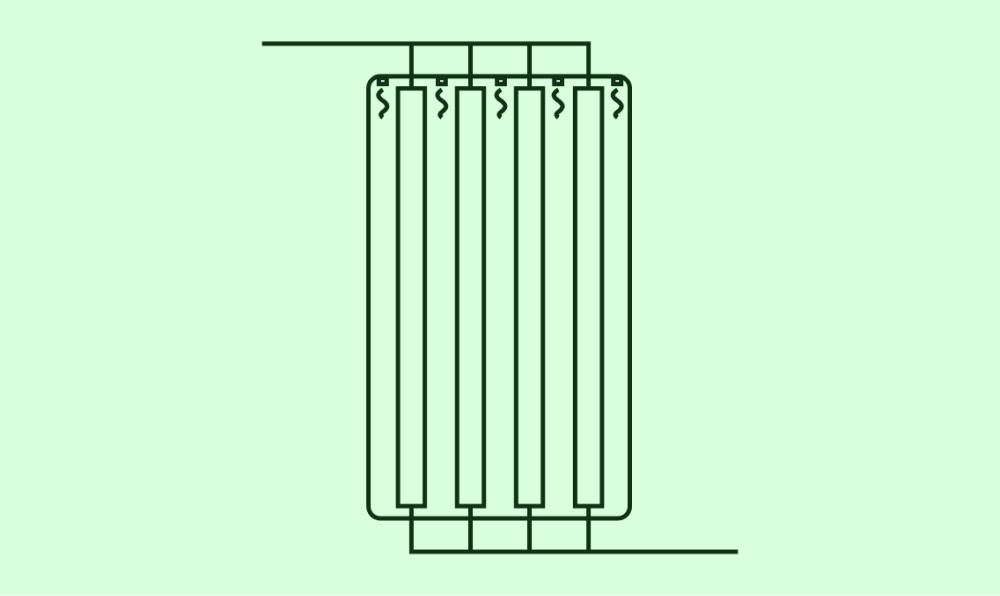

Fired tubular reactors

- Design similar to steam reforming

- Catalysts need high mechanical stability and low pressure drop

- Active metal coated / supported on carrier

- Pressure 20–40 bar / up to 700 °C

Clariant catalysts for fired tubular reactors

HyProGen 830 DCARB: Highly active and mechanically robust Nickel-based catalyst designed for high-temperature applications.

Our Catalysts

HyProGen™ 820 DCARB

Large-scale cracking Adiabatic reactor Catalyst

Nickel-based catalyst designed for high thermal stability, enabling higher inlet temperature to maximize conversion in adiabatic reactor

Product Benefits

- High thermal stability

- Active and robust catalyst

Customer Benefits

- Longer lifetime

- Higher conversion in adiabatic reactors

- Higher energy efficiency

HyProGen™ 821 DCARB

Large-scale cracking Adiabatic reactor Catalyst

HyProGen 821 DCARB is a highly active Nickel-based catalyst and an excellent alternative for Ruthenium catalyst with comparable stability and activity.

Product Benefits

- Highest activity close to Ruthenium

Customer Benefits

- Higher conversion in adiabatic reactors

- Higher energy efficiency

HyProGen™ 830 DCARB

Large-scale cracking Fired tubular reactor Catalyst

Nickel-based catalyst designed for high-temperature applications (550 – 750ºC) as in a reformer-type fired tubular reactor.

Product Benefits

- Well-proven with many references

- Excellent stability

- High activity

Customer Benefits

- Highest reliability and trustworthy

- Available in different shapes for tailor-made solutions

- Higher energy efficiency

HyProGen™ 850 DCARB

Precious metal catalyst for small-scale ammonia cracking

Highly active ruthenium-based catalyst designed for low-temperature and low-pressure applications (370 – 550°C)

Product Benefits

- High low-temperature activity

- High low-pressure activity

Customer Benefits

- Smaller and compact plant design

- Higher efficiency