Hydrogen Distribution

Revolutionary catalysts

for the energy transition

Green hydrogen from renewable energy sources, such as wind and hydro power, can be an abundant, versatile, and clean energy source. Consequently, there’s great interest in an energy transition away from fossil fuels toward a hydrogen economy, with the goal of decarbonizing transport and industry. There’s just one problem with hydrogen: its high volatility and very low density make it difficult and expensive to transport over long distances.

The most economically viable solution is to chemically convert hydrogen into a safer form for transportation, then reconvert it at point of use. There are currently two effective ways to »carry« hydrogen: via LOHCs, or ammonia. Clariant is proud to be one of the frontrunners in developing highly specialized catalysts for both pathways.

Hydrogen Transport via LOHCs

Process

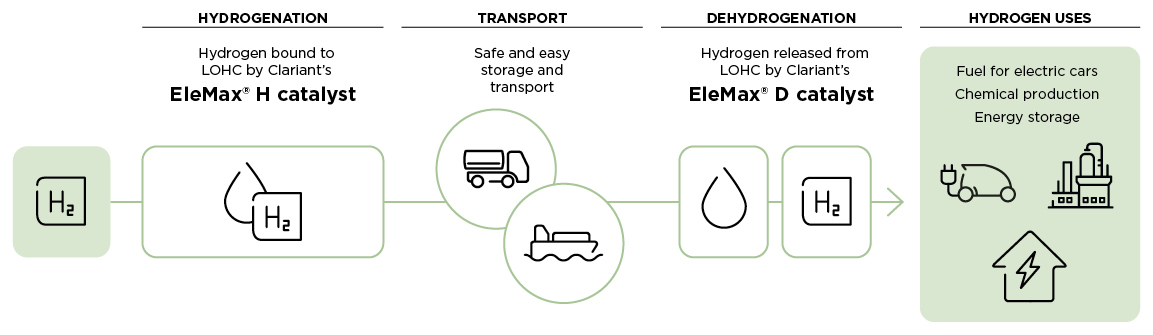

Liquid organic hydrogen carriers (LOHCs) are an ingenious means of transporting hydrogen by chemically binding the molecules. Developed by Hydrogenious Technologies, the method involves hydrogenation of the liquid organic hydrocarbon benzyltoluene using Clariant’s EleMax™ H catalyst to “store” hydrogen. At point of use, dehydrogenation with EleMax™ D »releases« hydrogen on demand. The tailor-made catalysts offer exceptional activity and selectivity for loading and unbinding hydrogen in order to optimize the life cycle and efficiency of LOHCs.

Hydrogenious Technologies’ revolutionary solution and Clariant’s specialized catalysts present a safer, more efficient alternative for storing and transporting high volumes of hydrogen.

For further information, please visit Hydrogenious LOHC Technologies