New Clariant Liquid Additive Masterbatch Reduces Yellowing in RecycledPET Bottles

- PET Enhancer offsets the color and clarity effects caused by increased use of recycled resin

- HiFormer® liquid additive technology is effective at low usage rates

- Formula works in single- and two-stage bottle lines, as well as injection and extrusion processes

- Approved for food-contact applications (FDA)

The new optical brightening products, which are part of the HiFormer® family of liquid masterbatch solutions and application technology, can be used in a wide variety of PET resin grades and processes, including injection-blow molding, injection molding and extrusion. Typically, PET resins are used in bottles and formed-sheet packaging. The additive has received approval for food-contact applications from the U.S. Food & Drug Administration.

"Packagers are under heavy pressure from consumers and environmental advocates to use more PCR in their products," explains Peter Prusak, Head of Marketing – Clariant Masterbatches North America, "but the recyclate tends to reduce or discolor the crystal clarity that PET is known for. Clariant's new HiFormer PET-enhancing additives promise to minimize this problem, opening new opportunities for more sustainable packaging."

The Clariant liquid masterbatches are resistant to sedimentation and segmentation so they offer extended storage-shelf life. They are also easy to use in gravimetric metering systems that ensure accurate dosing and clean operation. Let-down ratios as low as 0.025% have been used successfully.

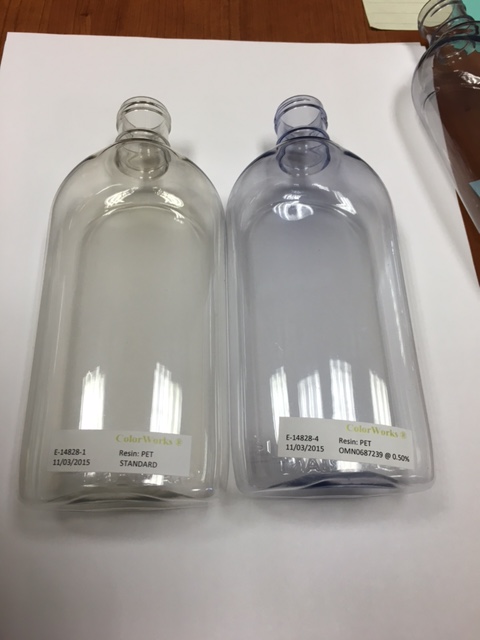

The new liquid additives were tested on a production scale blow-molding machine in Clariant's facility in East Chicago, IL. Bottles made using 25% recycled PET and 75% virgin PET and no brightening additive were compared against bottles made with the same PCR resin and the additive in concentrations of 0.025, 0.035 and 0.05%. While the unmodified bottles showed significant yellowing, all the bottles made with the HiFormer additive were visibly brighter (less yellow and more blue). This is evident in the following spectrophotometer readings:

The data in the two tests are quite different due to the fact that the bottles tested were essentially transparent, but trend is the same in both Test 1 and Test 2: the blue value decreases as the concentration of the optical brightener increases. This indicates that less blue light is absorbed by the surface of the PET and more blue light is reflected toward the viewer's eye. "The human eye perceives yellowness as dirty or hazy, while blue light is seen as cleaner and clearer," explains Prusak. "What is most significant, and what is most exciting to me, is how we can shift that blue value so dramatically just 0.05% additive loading.

HiFormer is Clariant's global brand that encompasses its high-performance liquid color and additive concentrates, dosing/handling equipment, expertise and service. It was created to help customers select the right masterbatch solution for their particular needs. Liquid masterbatches can be used in many of the same applications as pelletized material and in some cases they offer critical advantages to the packaging and consumer goods segments of the plastics industry. HiFormer liquid masterbatches are highly concentrated, so that less is needed to achieve brilliant, vibrant color, especially in translucent and transparent polymers like PET. Processing efficiencies can deliver high productivity at a low total cost. With its tailored carrier technology and customized dosing- and handling systems, HiFormer opens up new dimensions: fast and simple color changes, maximum flexibility, and high reproducibility of the defined color.