Clariant Healthcare packaging moisture-control solutions displayed at CPhI Worldwide 2017

Muttenz, October 20, 2017 – Clariant, a world leader in specialty chemicals, and its Healthcare Packaging business unit is featuring an expanded line of Equilibrium-Stabilizer products in Booth 42L40, in the Inno Pack area of the CPhI Worldwide 2017 exhibition being held October 24-26 in Messe Frankfurt, Germany.

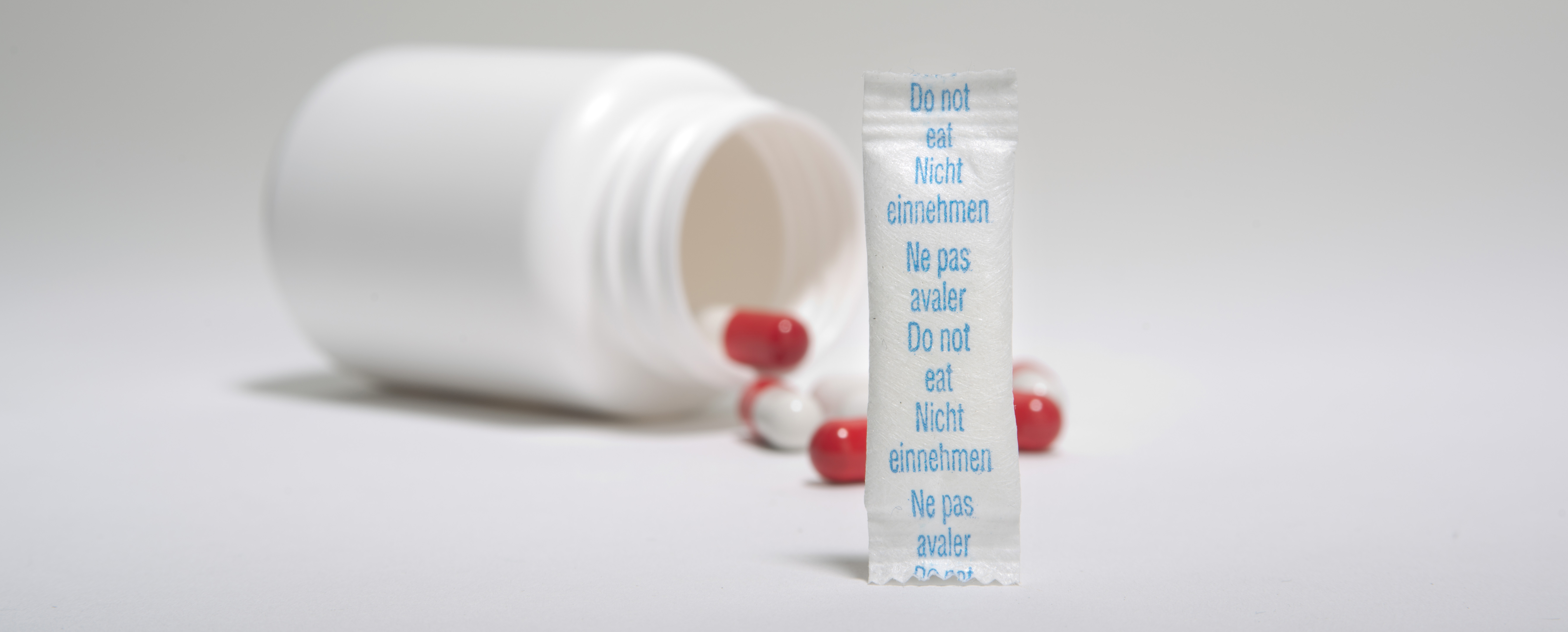

These solutions -- including EQ-Pak® packets, EQ-Can® canisters, EQ-Stopper® caps, and EQ-Bag™ -- deliver customized humidity control in all phases of the drug-product development cycle.

"While hydrolytic degradation of drugs can be addressed by removing substantially all humidity entering the packaging using a desiccant, other pharmaceutical properties may require the use of products that maintain a specific range of humidity throughout the shelf life of a drug product or ingredient," explains Elisa Le Floch, Pharm.D., Clariant Healthcare Packaging, Business Development Manager.

For instance, the ability of a micronized drug powder to reach optimally into a patient's lungs when dispensed by a dry-powder inhaler (DPI) can be strongly influenced by moisture. Excessive moisture can increase adhesive or cohesive forces between particles and alter particle size distribution. Excessive dehydration, on the other hand, will increase the electrostatic charge of the particles. Both can adversely affect the fluidization of the powder when patients inhale.

Another example is seen in packaging of gelatin capsules that enclose liquid or solid drugs. To maintain the integrity of the capsule over time, the gelatin forming the capsule needs to be plasticized by a significant amount of water. In a low-humidity environment, capsules may lose moisture and become brittle. Under high-humidity conditions, they will gain moisture and soften or fuse together. Because the physical stability of gelatin capsules is primarily associated with the gain or loss of moisture, packaging options are often limited. Active control of the humidity level within the packaging headspace – using Clariant' EQ-Pak and EQ-Can products – can provide new options for pharma packagers.

Clariant's EQ-Pak packets and EQ-Can canisters are specially engineered sorbents that can act as humectants (desorbers) and desiccants (adsorbers) simultaneously, maintaining a particular equilibrium relative humidity (ERH) inside product packaging. This line of standard equilibrium-stabilizer products can maintain ERH levels of 10%, 20%, or 30% to protect finished drug products in bottles or tubes, or to protect bulk ingredients (powders, capsules) in boxes or bags before, during, or after tableting or filling operations.

Now available in a new range of sizes, EQ-Pak packets (1 g, 2 g, or 2.5 g) or EQ-Can canisters provide relative humidity control for the contents of drug bottles or containers, while EQ-Stopper caps provide similar protection for tablets or capsules stored in tubes. EQ-Bags (37 g, 255 g, or custom sizes) protect bulk-quantity ingredients or products.

For more information, visit Clariant at CPhI in the Inno Pack area, Stand 42L20 or at www.clariant.com.

™ TRADEMARK® TRADEMARK OF CLARIANT REGISTERED IN MANY COUNTRIES.