Clariant extends EnviCat® catalyst portfolio to offer extruded SCR NOx solution for chemical and industrial applications

- Clariant builds on emissions catalysts range with introduction of latest NOx solution

- Clariant offers comprehensive emissions control technologies for upstream and downstream processes

- High selectivity catalyst effectively meets NOx reduction targets

Munich, June 26, 2018 – Clariant, a world leader in specialty chemicals, today announced the expansion of its EnviCat series of catalysts to include a high-performance solution for selective catalytic reduction (SCR) to combat nitrogen oxides (NOx).

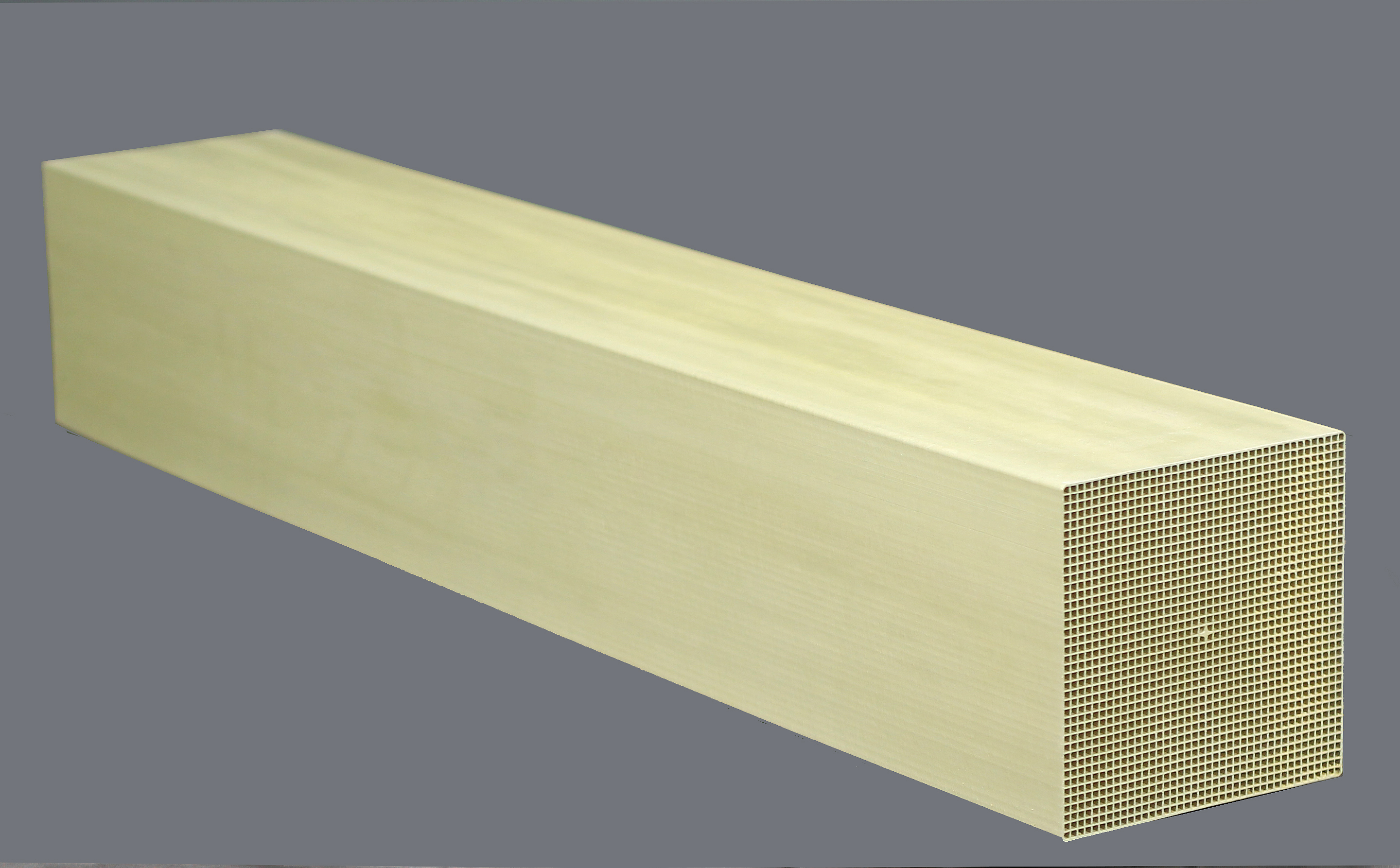

Clariant offers methodology to remove high levels of NOx via its EnviCat NOx SCR catalyst. The catalyst, an extruded honeycomb structured block made from a vanadium based composite, is designed to facilitate NOx reduction reactions in an oxidizing atmosphere. With high selectivity, EnviCat NOx significantly decreases NOx levels using ammonia as a reducing agent for the conversion of NOx pollutants into nitrogen and water. EnviCat NOx SCR has been demonstrated to effectively lower NOx emissions from gas fired exhaust streams and is well suited to a multitude of chemical and industrial applications.

NOx consists primarily of nitric oxide (NO) and nitrogen dioxide (NO2), of which NO2 is listed as one of six Criteria Air Pollutants under the Clean Air Act by the US Environmental Protection Agency. The product of fossil fuel combustion and industrial processes, NOx contributes to the formation of smog, ground level ozone, acid rain, and other hazards. The effect is significant and harmful to the environment, wildlife and human health. In particular, results of studies suggest that through the formation of pollutant particles penetrating into the lungs, NOx can aggravate or even cause respiratory diseases such as emphysema and bronchitis, among other serious health conditions.

The largest output of NOx emissions from non-automotive, stationary sources emanate from coal fired boilers, especially those in power generation. Petrochemical processes also produce large amounts of NOx, originating from utility boilers, cogeneration units, process heaters, steam methane reformers, ethylene cracking furnaces and fluid catalytic cracking (FCC) regeneration units.

Other major sources include kilns and furnaces from the cement, lime, ferrous and non ferrous metals industries.

"Clariant is delighted to be able to offer this important addition to our catalyst emissions reduction portfolio," said Stefan Heuser, Senior Vice President & General Manager, Catalysts. "Not only is the technology highly effective in mitigating the dangerous effects of NOx, it now enables us to provide our customers with cost-effective emissions solutions for both upstream and downstream businesses."

EnviCat NOx SCR is available in module designs of varying lengths and cell densities, is easily installed and can be configured to the plant's particular dimensions. The catalyst supports to achieve plant specific emission limit targets while effectively controlling NH3 slip under low to mid-temperature operation.

EnviCat® IS A TRADEMARK OF CLARIANT REGISTERED IN MANY COUNTRIES.