Clariant Additive Masterbatch Makes Black Plastic Packaging ‘Visible’ to Sorting Systems

- Allows continued use of color preferred for many iconic products

- Supports Clariant ‘Design for Recycling’ initiative

- Solutions available for numerous polymers and applications

Muttenz, August 26, 2019 – New Clariant CESA®-IR additive masterbatches are now available to make dark-colored plastics visible to the near-infrared (NIR) sensors used in automated polymer sorting systems. While many companies use black packaging to brand their prestige products, the problems it poses in recycling systems has led to calls for black to be phased out of the palette. The new masterbatches help to resolve that issue and allows increased recycling rates in Europe and elsewhere.

The new product range is part of a ‘Design for Recycling’ program at Clariant. Recognizing that recycling is the foundation of a Circular Economy, Clariant Masterbatches and its Packaging Market group, is mobilizing substantive resources across the packaging value chain to ensure that an ever-higher percentage of plastic packaging is recycled.

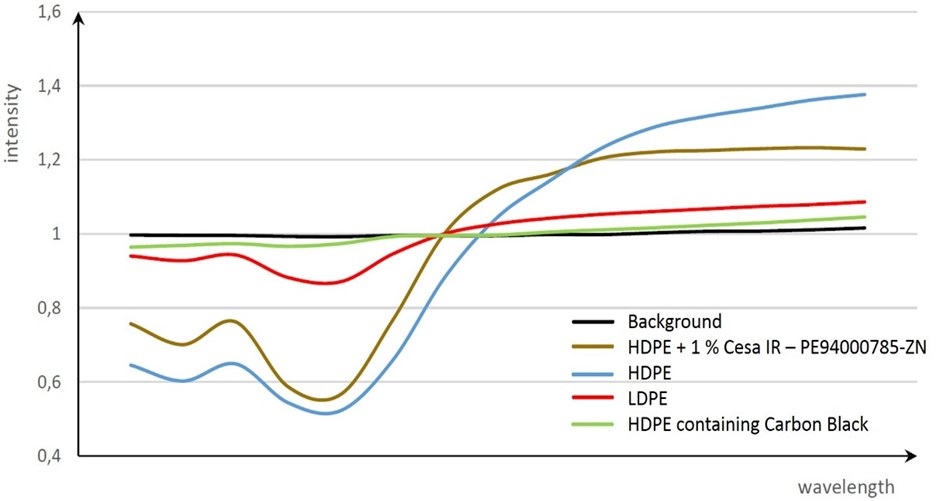

In most automatic sortation systems, infrared light is beamed onto packaging materials and, because different polymers reflect that light differently, NIR sensors can discriminate between high-density polyethylene, low-density polyethylene, polypropylene, polyester and various other commonly used polymers in today’s packaging. Unfortunately, the carbon black pigments typically used to make black plastics absorb all or most of the NIR light shone at them. As a result, the sorting sensors cannot even “see” the black packaging, much less sort one polymer from another.

“As a result of this phenomon,” explains Alessandro Dulli, Clariant Masterbatches Global Head of Packaging, “much of the dark-colored materials entering the recycling stream has not been recovered. For that reason, many brand owners have been pressured to move away from black for environmental reasons. In close collaboration with these brand companies and as a leader in sortation technology, Clariant has developed a way to achieve a persuasive black color in plastics without compromising the essential detectability during recycling process."

Specific CESA-IR formulations have been developed to enable IR-detectability of black HDPE and LDPE in injection and extrusion blow-molded products; black polypropylene (PP) in films and injection-molded products; and black PET and C-PET in sheets and film.

In testing conducted by TOMRA Sorting Recycling, a Norwegian company that is a leader in the field of instrumentation for recycling solutions, polypropylene (PP) containing carbon black was essentially indistinguishable under NIR radiation from background surfaces such as a conveyor belt.

However, the same material made using another coloring system including CESA-IR additive masterbatches was readily detectable, with reflectivity levels approaching those of uncolored PP.

Discover more on how Clariant is supporting a circular economy for plastics through sustainable innovations and collaborations. Meet Clariant leaders and partners at our “Symphony of Collaboration” K 2019 media event on October 17, 8:15am media breakfast followed by 9am press conference, Booth 8AJ11.CESA® IS A TRADEMARK OF CLARIANT REGISTERED IN MANY COUNTRIES.