Clariant contributes to China's carbon neutrality goal with innovative MegaMax® catalyst for CO2-based methanol synthesis

- MegaMax series catalysts enable CO2-based methanol synthesis with high selectivity, activity, and longevity

- The catalysts formulation can be readily applied to a wide range of plant types and technologies

- CO2 to methanol reference tests showed high performance even under low pressures and temperatures

Munich, June 21, 2021 – Clariant's MegaMax catalyst series for CO2-based methanol production helps China reach its carbon neutrality target. Capturing and converting CO2 emissions is a cornerstone of the technology roadmap for addressing climate change. Synthesizing methanol from CO2 is a particularly valuable approach because methanol forms a building block for thousands of chemical products such as plastics, paints, cosmetics, and fuels — including providing an energy storage carrier for hydrogen.

Stefan Heuser, Senior Vice President & General Manager at Clariant Catalysts, commented, "At Clariant, we are firmly committed to continuously improving our own sustainability performance, as well as that of our customers. Our continuous innovations – like CO2-based methanol production enabled by our MegaMax catalyst – will play a key role in helping customers in China and around the world considerably reduce carbon emissions, and achieve critical climate targets."

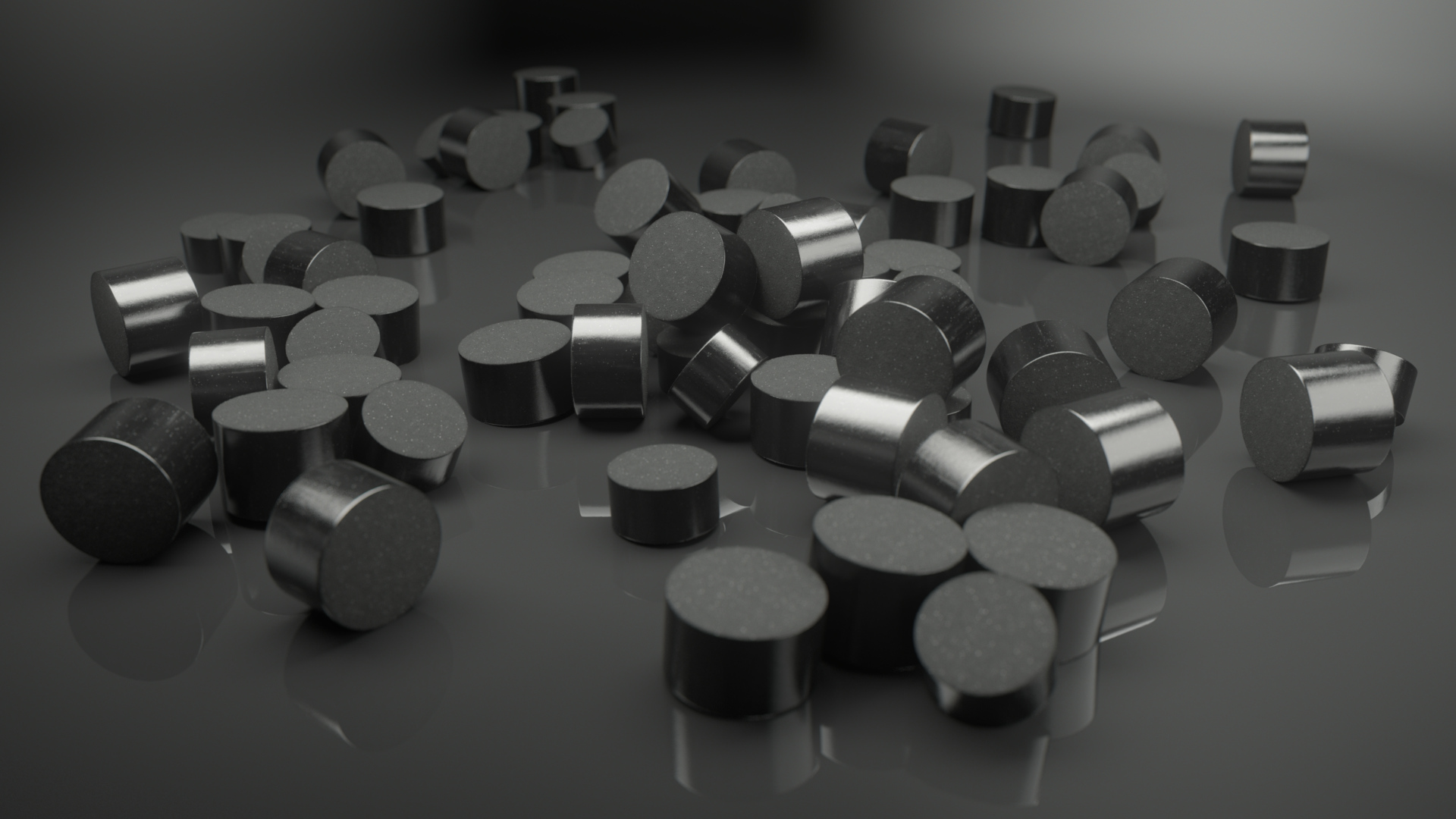

This product line is designed for methanol producers worldwide and is based on the well-proven copper-zinc-alumina system. The special material composition now outperforms previous generations and benchmarks in carbon efficiency, mechanical stability, and product lifespan.

Clariant's MegaMax catalyst successfully passed a qualification test in the Methanol demonstration unit of Air Liquide's Innovation Campus Frankfurt in Germany. The tests demonstrated a high conversion ratio, with a per-pass CO2 conversion rate of up to 30-40% using H2/CO2 feed. By-product formation was also low and the process achieved high selectivity. Additionally, the catalysts have shown improved stability and low deactivation, permitting an expected long product lifetime.

With the confirmed high energy efficiency and excellent performance, Clariant's MegaMax is officially qualified for future use in commercial CO2-based methanol plants.

Clariant has nearly 50 years of experience in methanol catalysts and is a globally renowned catalyst manufacturer. The broad portfolio of full catalytic solutions is designed to meet customers' needs for different scales, processes, and feedstocks.

To help customers reliably achieve their efficiency and emission targets even under flexible conditions, Clariant provides strong engineering service support to work with process partners on solutions for green methanol production and the clean-up of unconventional syngas streams.

As part of Clariant's own sustainability targets, Clariant Catalysts is developing next-generation catalysts with even better performance. These solutions will assist in more environmentally friendly methanol production and meet carbon neutrality goals in China and worldwide.

MegaMax® IS A TRADEMARK OF CLARIANT REGISTERED IN MANY COUNTRIES.