Liquid flame retardants for epoxy resins

our EXOLIT™ EP line for halogen-free safety and advanced processing

Epoxy resins with built-in fire safety and full-out compatibility with modern applications

From 5G phone circuits to composites for e-mobility, epoxy resins are used for some of the most cutting-edge applications. The liquid non-halogenated flame retardants from our Exolit™ EP line match this with a new level of compatibility and safety.

Low viscosity – high phosphorus content and sustainability

Exolit™ EP 360 and EP 390 are phosphorus flame retardants incorporated into low-viscosity epoxy resin. This gives them broad compatibility with these types of thermosets, to which EP 360 also brings mechanics-enhancing epoxy functionality.

Due to their low viscosity, the solutions are ideal for modern solvent-free processing techniques, and their particle-free nature makes them attractive for thin E&E applications. They combine high efficiency with favorable environmental and health properties like low fire smoke toxicity, predestining them for use in transportation composites and other high-standard applications.

Find out more about our Exolit AP™ solutions

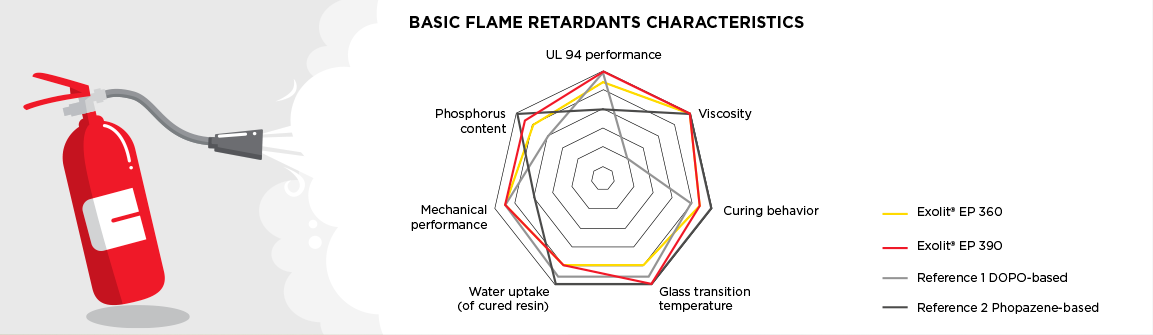

More complete performers than comparable products

The one-two-three of fireproofing epoxy

KEY BENEFITS OF OUR SPECIAL EP LINE

1.Ideal solution for all common solvent-free processes like infusion, liquid compression and resin transfer molding

2.Relatively low dosage needed to meet the required flame retardant performance of materials and products

3.High glass transition temperatures in epoxy composites possible, enhancing their suitability for high-temperature applications

Are Exolit™ EP 360 and 390 a sure-fire solution for epoxies? Christian Battenberg has the answer

»With their low viscosity and high phosphorus content, our products considerably facilitate giving reliable fire safety to epoxy resins. No more pesky sediments, excellent curing performance – and even a reactive option that enhances the material.«

Dr. Christian Battenberg

Global Segment Manager Thermosets, Flame Retardants, Clariant

Some weighty reasons for using our products

> %PHOSPHORUS

content (by weight) in Exolit™

EP 390 for high protection

at low dosage

~EEW

(epoxide equivalent weight)

in Exolit™ EP 360,

allowing it to partake in

cross-linking

%PHOSPHORUS

content (only!) by weight

necessary from EP line

sufficient to achieve UL V-0

rating in epoxy resins