DODIFLOW™

Additive Range

for Marine Fuels

Clariant's DODIFLOW™ Marine Fuel additive range can effectively mitigate challenges in marine fuel handling by addressing issues related to pour point, cold filter plugging point and fuel instability. These specialized additives help enhance the overall handling properties of marine fuels, delivering reliable performance even under demanding operating conditions.

Premium Pour Point Depressant Additive to Improve the Cold Flow Properties of MGO

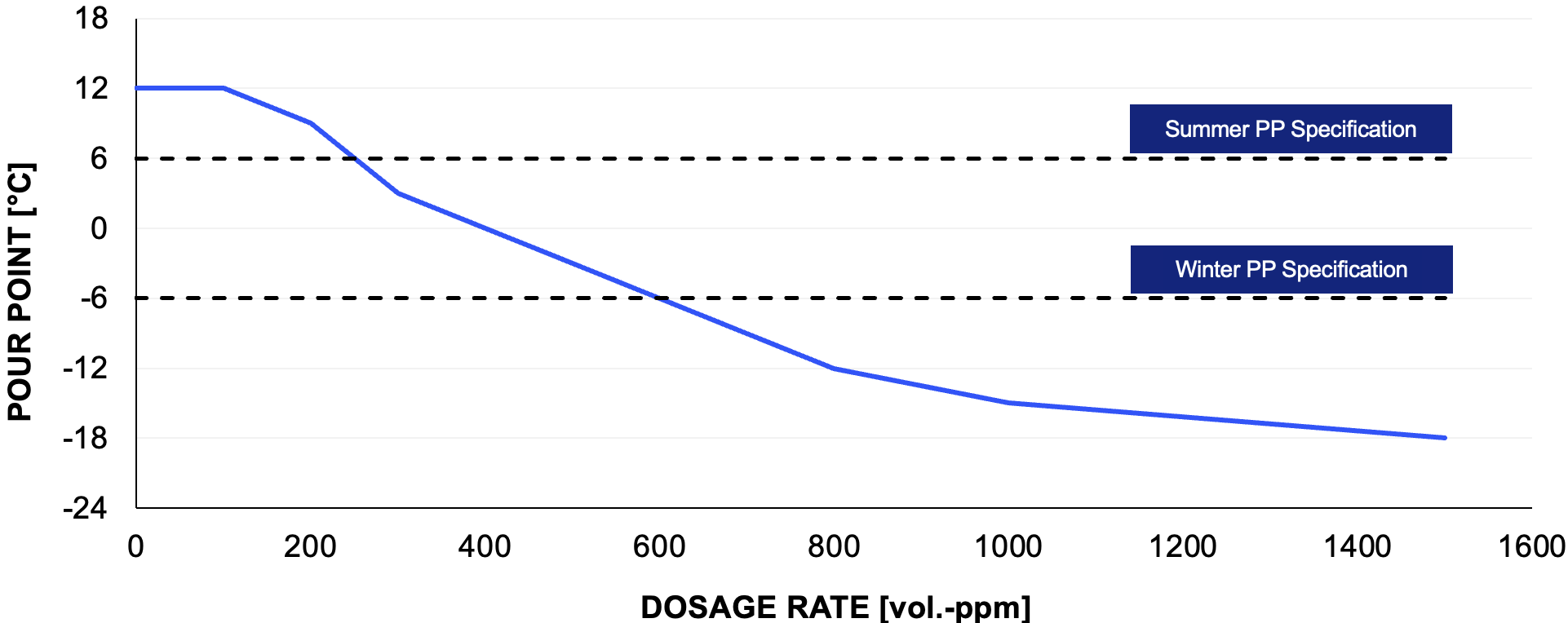

Marine Gas Oil (MGO) has a pour point (PP) specification ranging from +6 °C to -6 °C, depending on the season (ISO 8712:2024). DODIFLOW™ 6087 effectively improves both the pour point and cold filter plugging point (CFPP) of MGO, enabling correction of off-spec fuels and safeguarding bunkering operations during cold weather. It is suitable for DMX, DMA, DFA, DMZ, DFZ, DMB, and DFB fuel grades.

Bio-MGO and IMO 2030 Fuels

The IMO’s mandate for a 40% reduction in carbon emissions by 2030 (IMO 2030) presents a significant challenge for the shipping industry. Achieving these targets without compromising operability, storage stability, or compliance with ISO 8217 specifications requires innovative solutions.

Blending higher percentages of used cooking oil methyl ester (UCOME) into Marine Gas Oil (MGO) is emerging as a practical approach. UCOME blends in the range of 24–30% (B24–B30) are gaining traction as viable options to help the maritime sector meet its emissions goals.

However, UCOME typically has a higher cloud point than MGO, meaning it begins to form crystals as the blended fuel cools. This can lead to:

- An elevated pour point due to the UCOME component, making the fuel sluggish

- Increased formation of wax crystals, which can block fuel filters.

- Incompatibility between UCOME and MGO, causing phase separation at lower temperatures.

- Greater risk of operational issues during cold weather storage and handling.

DODIFLOW™ 6088 supports the integration of bio-derived components such as UCOME — including palm- and tallow-derived variants — into MGO, enabling blends with up to 40% bio-content (B40).

Example of Pour Point (PP) response of B30-MGO when dosed with DODIFLOW™ 6088

Specialized Pour Point Depressant designed to improve Cold Flow properties of VLSFO

Very Low Sulfur Fuel Oil (VLSFO) is a complex blend of multiple refinery streams designed to meet the 0.5% sulfur specification limit mandated in the IMO 2020 directive. These diverse sources can negatively affect the fuel's viscosity, pour point and overall stability.

DODIFLOW™ 8421 is pour point depressant, which is designed to improve cold flow properties of VLSFO to help achieve the IMO 2020 pour point specification <30° C. It can also help by preventing wax drop-out and sludge formation during storage and bunkering operations.

Fuel Stability Enhancers

DISPERSOGEN™ 2020 is a fuel stability enhancer that’s specifically designed to improve the consistency of VLSFO and support the compatibility of blended refinery streams. It works by inhibiting the precipitation of waxes and asphaltenes in LSFO and VLSFO blends. It can also help to improve the results of Total Sediment Existent (TSE, ISO 10307-1) and Total Sediment Potential (TSP, ISO 10307-2) tests.

Clariant’s DISPERSOGEN™ 2020 can be used as a preventative measure to allow LSFO blending across all regions, which will help global refiners meet new regulation standards with fuel oil blends that will remain stable and compatible.

Clariant’s Research and Product Development Excellence Effectively Addresses Marine Fuel Challenges

Clariant Refinery is a recognized leader in additive solutions that optimize cold flow properties and enhance storage stability across various fuel types, including specialized solutions for marine fuel application. We are committed to helping customers overcome operational obstacles through innovative, state-of-the-art technologies. Our robust R&D capabilities and advanced laboratory testing equip our technical experts with the tools to develop additive solutions that deliver proven, high-performance results.

At the core of Clariant’s global research efforts is the Clariant Innovation Center in Frankfurt. This central hub drives our commitment to excellence and continuous improvement. To learn more about this facility, click here.

The Crude and Fuel Oil Center of Excellence located in Bradford, UK is our competence laboratory for our experienced technical service team to support customers with their crude and fuel oil treatments, as well as advising on the selection and use of PPD/Dispersant on a global level.

Clariant is dedicated to customer-centric application development, with a focus on creating fuel additives that enable our customers to confidently meet handling and specification requirements.