Transforming plastic waste into wealth

How Clariant helps to turn plastic waste into high-quality diesel

Today, only approximately 9% of plastic waste is being recycled. It is clear, that while plastics pollution is a global issue, the chemical industry has taken up this challenge. As Clariant has been driving sustainability for years as an integral part of its strategy, the company has also joined forces with several partners to ultimately increase this rate globally by transforming plastic waste into valuable chemicals.

Recently, Clariant Catalysts has teamed up with the VUCHT Research Institute of Chemical Technology, which is part of the Slovakian chemical company Duslo. By using their proprietary technique and Clariant’s HYDEX™ E catalysts, VUCHT has successfully converted plastic waste into premium winter diesel, i.e. diesel fuel which does not gel even in extremely cold weather with temperatures as low as -30°F (-34°C). Scaling up to near-plant capacity was the ultimate test of the practicality of VUCHT’s proprietary diesel production process.

How does Clariant contribute to this innovation?

Let’s take one step back and get to know more about Clariant’s solution HYDEX™ E. The highly selective de-waxing catalyst is designed to improve flow properties during cold weather conditions. HYDEX E maintains its predecessors’ exceptional robustness and flexible application, yet considerably increases diesel yield while reducing undesired by-product formation. Consequently, producers not only benefit from higher cost-efficiency, but also improved sustainability.

How does the process work?

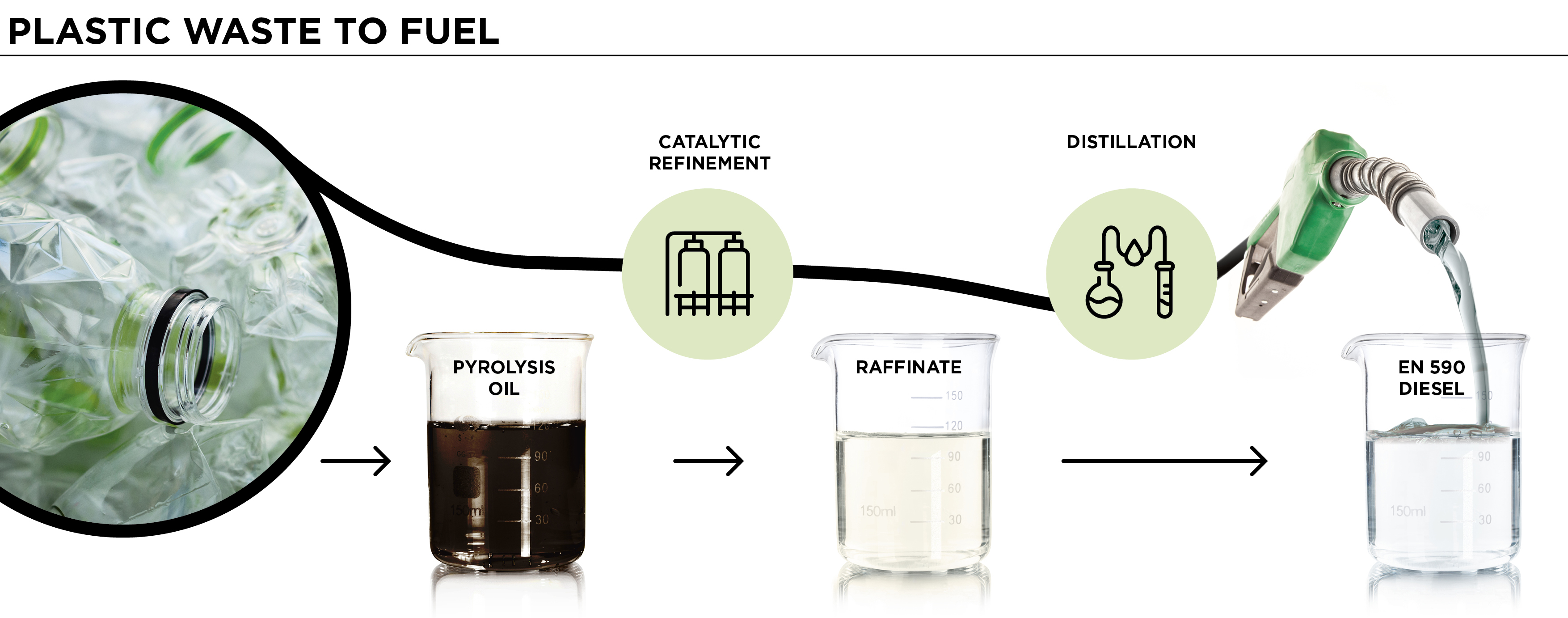

VUCHT uses a pyrolysis process to convert plastic waste collected in Slovakia (such as polyethylene, polystyrene, polypropylene and PET) into diesel fuel. The process thermally degrades the plastic at temperatures above 300°C (530°F), converting it into liquid oil comprised of various hydrocarbon compounds. Recently, the institute developed a proprietary technique to further convert the liquid oil into a high-quality fuel distillate known as winter diesel. As plastics and fuels are both mainly made from natural gas or crude oil, turning one into the other has major implications for sustainable and lucrative fuel production. The efficacy of this groundbreaking process has now been proven in a demonstration plant in Slovakia.

Stefan Heuser, Senior Vice President & General Manager at Clariant Catalysts: “Upgrading gas oil fractions to more valuable products has become essential for improving refinery economics. Clariant is committed to supporting this customer need through innovations such as HYDEX E. We are honored to partner with VUCHT in their pioneering plastic waste-to-winter diesel technology, and very pleased about the outstanding performance of our next-generation catalyst in the process.”