Clariant Oil Services Treats Heavy Oil in Indonesia Steam Flood Facility

Benefits

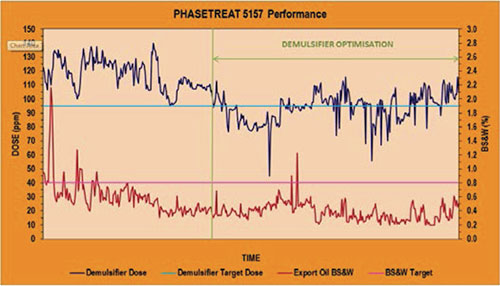

- 21% Reduction in chemical usage

- Annual saving of $231,000 realized

- Reduced export oil excursions through 30% improvement in BS&W

Background

A major international oil company operating a heavy oil steam flood operation in Indonesia was experiencing separation and crude dehydration difficulties in one of its central gathering stations (CGS). The field is around 35,000 acres and typically produces 197,000 bpd of 20.8º API crude, together with 1,100,000 bpd of produced water from approximately 5,000 rod pump wells. The fluids are processed in five CGS through a 3-stage separation train with temperatures ranging from 71°C to 98°C.

The composition of the heavy crude supports stable oil-in-water and water-in-oil emulsions, and treating these emulsions is considered the most critical challenge at the facility. The operator altered some of the process controllers and, as a consequence, frequent excursions beyond the crude export specification of 0.8% BS&W resulted. In order to counteract the excursions, the demulsifier dose was increased to approximately 120 ppm.

As part of the integrated chemical management system, Clariant Oil Services was asked to work with the operator to investigate the nature of the excursions and to provide recommendations to resolve the issues.

Clariant Oil Services Solutions and Value Delivered

Clariant Oil Services uses the LeanSigma method to improve operations that are process driven. This is a structured and standardized approach that uses the DMAIC cycle where we Define the problem, Measure how big the problem is, Analyze the problem to identify the root causes, Improve the problem by defining solutions, and Control the problem by implementing the best solutions. The operator was very supportive of this method, and implementation of the solutions led to optimization of the process facilities, which included the demulsifier application.

The dose rate of Clariant Oil Services’ PHASETREAT 5157 demulsifier was reduced to approximately 95 ppm, which has since generated an annual savings of $231,000. Additionally, the optimization process improved the BS&W by 30%, greatly reducing the number of excursions beyond the export oil specification.

This information corresponds to the present state of our knowledge and is intended as a general description of our products and their possible applications. Clariant makes no warranties, express or implied, as to the information’s accuracy, adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use of this information. Any user of this product is responsible for determining the suitability of Clariant's products for its particular application.*Nothing included in this information waives any of Clariant’s General Terms and Conditions of Sale, which control unless it agrees otherwise in writing. Any existing intellectual/industrial property rights must be observed. Due to possible changes in our products and applicable national and international regulations and laws, the status of our products could change. Material Safety Data Sheets providing safety precautions, that should be observed when handling or storing Clariant products, are available upon request and are provided in compliance with applicable law. You should obtain and review the applicable Material Safety Data Sheet information before handling any of these products. For additional information, please contact Clariant.

*For sales to customers located within the United States and Canada the following applies in addition: NO EXPRESS OR IMPLIED WARRANTY IS MADE OF THE MERCHANTABILITY, SUITABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE OF ANY PRODUCT OR SERVICE.

Copyright © Clariant International Ltd, 2012.