Feed Purification

Advanced catalysts

for any impurity in any feed

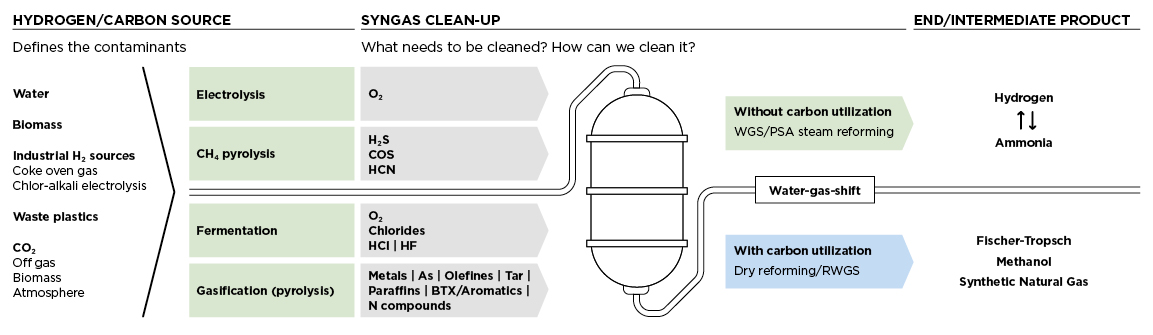

Feed gas used to produce more sustainable fuels and chemicals typically comes from sources which contain many metal and inorganic impurities. Unless removed, contaminants can severely impact downstream processes. Even low concentrations of impurities can affect the performance and lifetimes of downstream catalysts, undermining overall process outcomes. The source of hydrogen or carbon feed defines the impurities present, and the purification steps required.

Our Complete Solutions and Support

The challenge in feed gas purification is to ensure the most effective yet economical solution. The guard bed must capture a wide range of impurities, which can vary in concentration over time. However, the process must be as simple as possible to minimize costs, as renewable pathways strive to compete with established fossil-based sources.

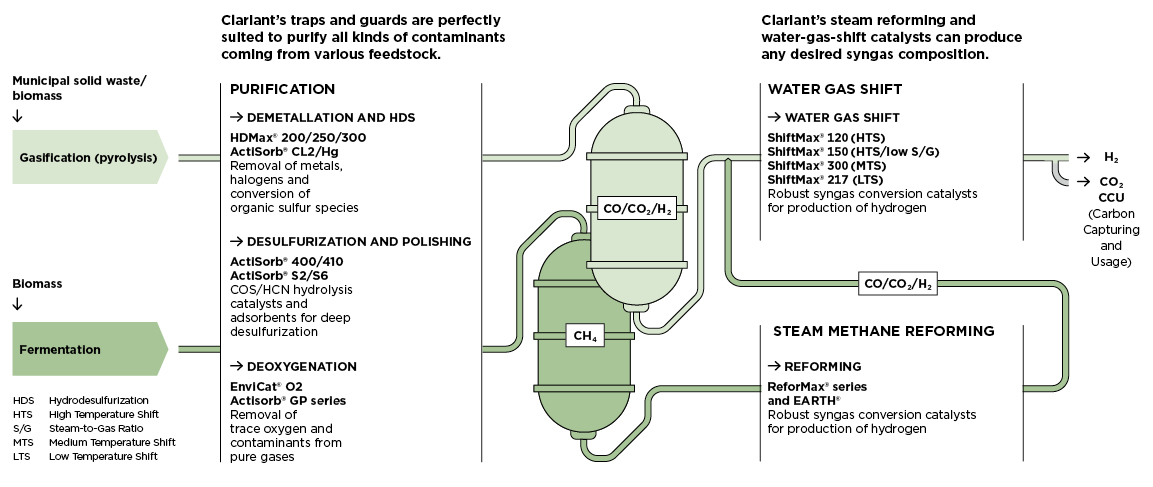

With our extensive experience in novel gas compositions, Clariant provides expert advice and optimized catalysts and adsorbents for cost-effective purification of all feed streams, impurities, and plant designs. Our comprehensive and innovative portfolio for upgrading green syngas covers even the most challenging gas requirements, as well as special cases such CO₂ and H₂ purification.

Production and purification of hydrogen for industrial and catalytic use

A spectacular growth in renewable hydrogen applications in the coming years is expected and is a necessary evolution in mankind’s energy management to help achieve carbon neutrality. Hydrogen underpins the vast majority of important chemical and fuel processes and Clariant is committed to supporting the delivery of clean hydrogen technologies with our ever-evolving syngas portfolio but also in new purification applications such as de-oxygenation of green hydrogen produced by electrolyzers. Clariant’s EnviCat emission control catalysts have been applied in de-oxygenation application for many decades and we are happy to recommend suitable cost-effective solutions for generating high purity hydrogen.

Desulfurisation and demetallation

of gas streamsBoth traditional fossil feedstocks as well sustainable feedstocks such as biomass or municipal solid waste contain significant inorganic impurities which lead to the generation of e.g. sulfur, halide and metal species downstream of the gasification/pyrolysis/ thermal process.

Traditionally these impurities are managed by a combination of wet and dry scrubbing as well as electrostatic precipitation. Here, in many cases for new plants it is possible to adapt known gas cleaning processes and materials. However, due to issues of process scaling there is frequently a greater requirement for the catalytic and dry scrubbing technologies to manage challenging chemical species such as organic sulfur and HCN.

Clariant’s extensive experience in this area combined with a comprehensive portfolio of Actisorb materials make us the perfect partner for realizing high purity feedstocks for downstream production of sustainable fuels and chemicals.

Upgrading syngas using the

water-gas-shift reactionClariant has a comprehensive portfolio of water gas-shift catalysts including Fe-based high temperature shift catalysts as well as sour-gas shift catalysts. These catalysts in particular are frequently employed in syngas upgrading as their robust nature can reduce the need for other gas cleaning technologies.

The downstream applications including hydrogen production, methanation to synthetic natural gas, Fischer Tropsch synthesis and methanol production.

Carbon dioxide purification for

CCUS applicationsWith a growing demand for more sustainable fuels the need for sequestering carbon or utilizing CO₂ as a raw material grows exponentially each year. In each case however there are certain requirements for the purity of the carbon dioxide source in order to reliably and safely operate the downstream processes.

The potential sources for carbon dioxide are extremely diverse including biogas upgrading, chemical and industrial off-gases, fermentation processes, direct air capture and more.

Clariant’s wide range of adsorbents and catalysts allow us to deliver high performance solutions which enable optimized system costs for passive adsorbent systems to remove inorganic contaminants, as well as more sophisticated catalytic purification systems where e.g. VOC or oxygen removal are required.

General gas purification

Biogas and CO₂ cleaning

Deoxygenation of hydrogen

Sulfur removal

Syngas conditioning

Steam methane reforming

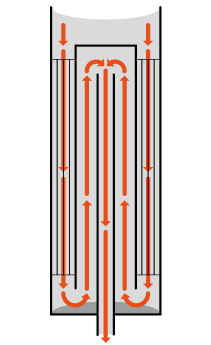

EARTH™ Technology

Innovative drop-in assembly for reformer tubes that greatly increases catalyst activity and heat recovery, thus minimizing energy consumption and CO₂ emissions

CONTACT US

Key results achieved:

- >30% fuel savings

- >10% decreased CO2 footprint

- ~20% decreased pressure drop

- >20% increased furnace firebox efficiency, i.e. the energy absorbed by the conversion process versus the total energy liberated in the furnace

- ~50% decreased steam export