Clariant and Jiangsu Jinneng partner in catalytic off-gas treatment at Shandong Qilu Plasticizers’ phthalic anhydride plant

- Clariant catalysts and Jiangsu Jinneng technology purify emissions from Shandong Qilu Plasticizers’ phthalic anhydride (PA) plant

- Clariant’s EnviCat® VOC catalyst removes up to 99% and beyond of VOCs and CO with exceptional conversion and cost efficiency

- Shandong Qilu Plasticizers plant also uses Clariant’s OxyMax® PA 690 catalyst to produce 70,000 metric tons of PA annually

Munich, July 23, 2020 – Clariant and Jiangsu Jinneng’s collaboration in off-gas treatment is off to a strong start in 2020. Jiangsu Jinneng’s innovative catalytic combustion unit and Clariant’s highly effective EnviCat VOC catalyst have been in successful operation at the phthalic anhydride (PA) plant of Shandong Qilu Plasticizers Co. Ltd. since November 2019. The partners’ advanced emission control solution is used to purify production off-gas, which contains volatile organic compounds (VOCs) and carbon monoxide (CO). Located in Zibo, Shandong province, the plant already employs another Clariant product, the high-yield OxyMax PA 690 catalyst, to produce 70,000 metric tons of PA annually.

Kevin Chan, Head of Clariant Catalysts China, stated, “We are honored to serve Shandong Qilu Plasticizers with a tailor-made sustainable emission control solution, together with our technology partner, Jiangsu Jinneng. Thanks to the catalyst’s adaptable design, and Clariant’s sophisticated production capabilities, EnviCat VOC could be customized to Shandong Qilu Plasticizers’ precise process requirements to ensure optimum efficiency and performance.”

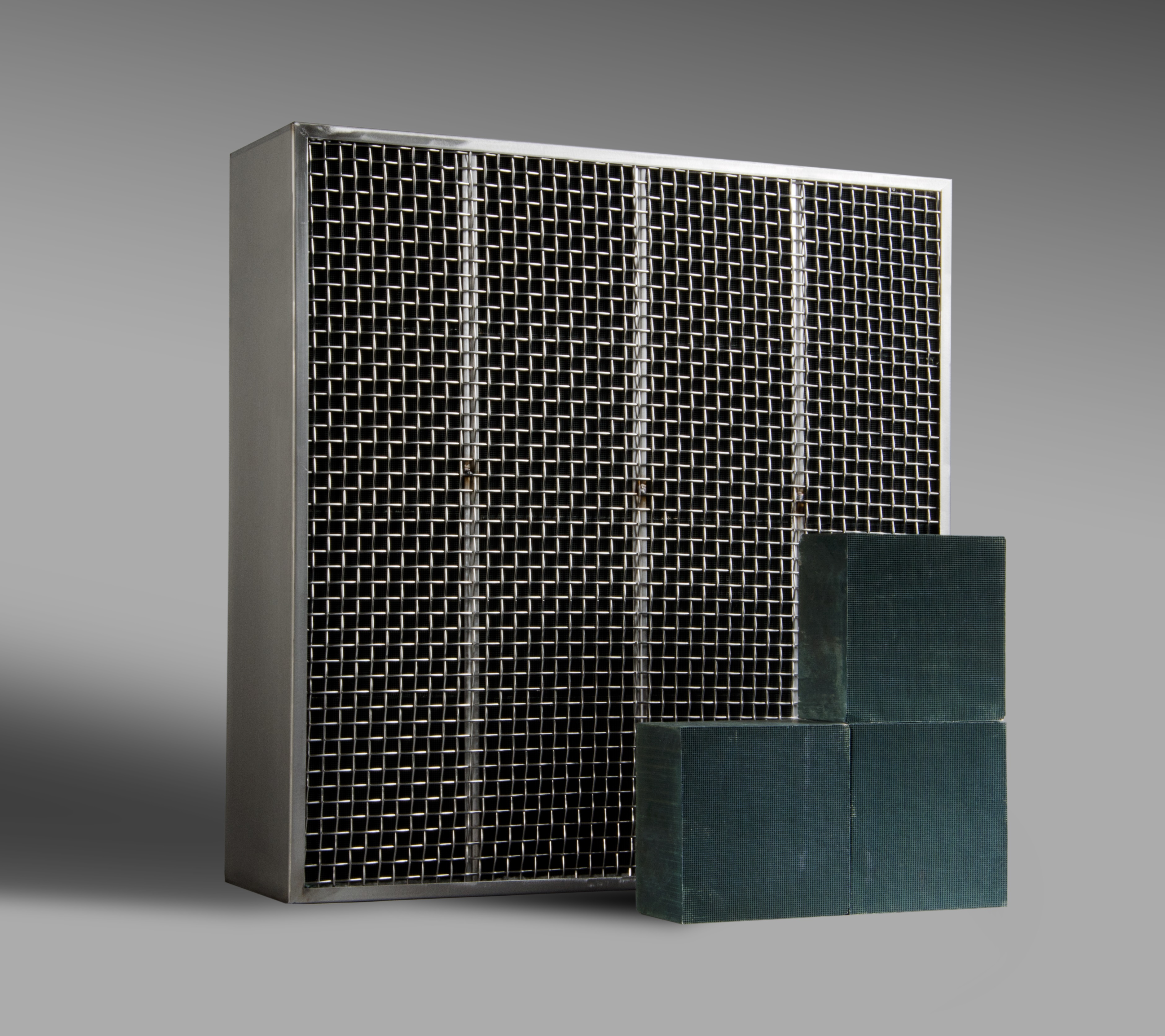

Clariant’s extensive experience in off-gas treatment catalysts has resulted in the development and widespread use of its high-performance EnviCat VOC. The catalyst is proven to effectively remove both VOCs and CO with an excellent conversion efficiency of up to 99% and beyond. It operates at up to 400°C lower temperatures compared to other off-gas purification methods, such as recuperative thermal oxidation. This greatly reduces fuel consumption and equipment stress, leading to potential significant economic, operational, and safety advantages.

A subsidiary of Chinese Bluesail Chemical Group, Shandong Qilu Plasticizers is the largest producer of industrial plasticizers, and one of the leading manufacturers of PA in China. It has also been one of the first companies in the industry to adopt sustainable catalytic off-gas treatment. Sun Chang Jun, General Manager at Shandong Qilu Plasticizers, expressed his satisfaction with the results, saying, “We are very pleased with Clariant and Jiangsu Jinneng’s solution. After a smooth start-up, the catalysts are performing with excellent efficiency, as promised. As sustainable operation is always our priority, this is an essential and optimal solution for our company. It enables us to successfully meet the latest emission regulations of China’s 13th Five-Year Plan.”

Jiangsu Jinneng Environmental Science and Technology is a certified high-tech enterprise with more than 20 years of experience and over 30 patents in VOC abatement technology. More than 30 Chinese and international chemical plants employ the company’s catalytic off-gas technology and equipment. Chen Min Dong, General Manager at Jiangsu Jinneng, commented on the partnership, “Jiangsu Jinneng and Clariant have collaborated in off-gas treatment in China for over 10 years. We strengthen each other’s advanced technologies to offer each plant operator the ideal solution for their company and the environment.”

® TRADEMARK OF CLARIANT REGISTERED IN MANY COUNTRIES.