Reactive emulsifiers for the manufacture of water-resistant binders – Emulsogen™ CPA 100 XS and Emulsogen™ CPN 100 XS

Clearly evident

Reactive emulsifiers can be anchored to polymeric binders to prevent emulsifier migration and its adverse effects on paint performance and the environment.

When emulsifiers leach out of a polymeric film, it turns from clear to white and adheres less well to substrates. In the applied paint, this translates to impaired water resistance and aesthetic defects such as snail trails.

With Emulsogen™ CPA 100 XS and Emulsogen™ CPN 100 XS, we solve these issues.

Download our brochure to learn more

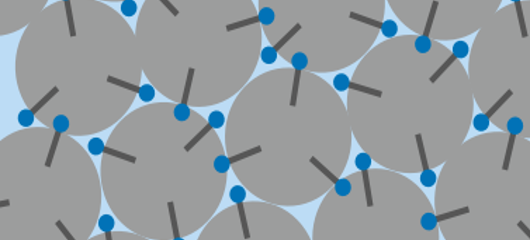

Conventional emulsifier

Single polymer chain level

Organized as polymer beads in water

Reactive emulsifier Emulsogen™ CPN 100 XS/Emulsogen™ CPA 100 XS

Film formation level

Surfactants drifting towards

interfaces if not bound

Final polymer film

While the covalent reactive emulsifier stays put in place, conventional emulsifiers can, depending on their structure and size, migrate to interface, leading to water pockets and poor films.

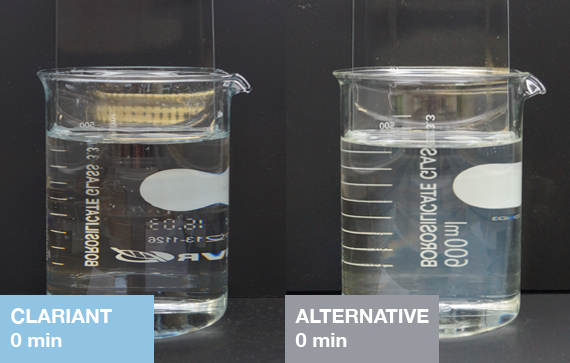

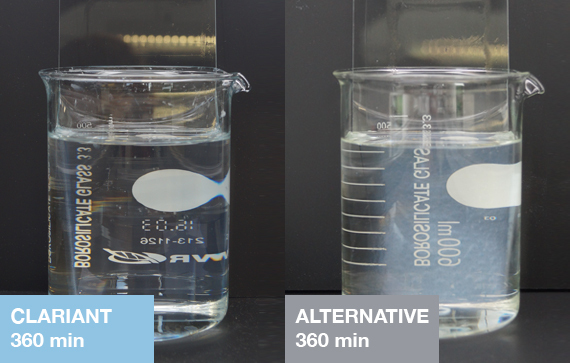

Water whitening in pure acrylic formulations

The binders made with Clariant’s emulsifiers are clear and flawless. The binder with the alternative turns turbid almost immediately.

Even after 6 hours, the binder with Clariant’s emulsifiers is still clear compared to the alternative.

Product benefits you will experience

Anchored to polymeric binders to prevent emulsifier migration from the dried coating and thus avoiding any side effects

Giving more stable polymer films, showing excellent water resistance compared to both non-reactive emulsifiers and other market alternatives

Available in anionic (Emulsogen CPA 100 XS) and non-ionic (Emulsogen CPN 100 XS) form with the possibility to use in combination to reduce coagulation and reach smaller particle sizes