Transforming ethane into essential chemical building blocks

Clariant's OxyMax™ E catalyst stands at the core of the revolutionary EDHOX™ process, utilizing oxidative dehydrogenation (ODH) of ethane to deliver fundamental building blocks that shape our modern world in a more sustainable way. Our advanced technology enables the efficient production of ethylene and acetic acid, essential chemical building blocks used to synthesize a broad range of materials and chemicals forming the backbone of countless consumer products. Ethylene enables production of everyday items including polyethylene plastics for packaging, durable consumer goods, polyester-based textiles, airplane antifreeze, construction materials, synthetic rubber found in tires, and foam insulation materials to name a few. Acetic acid serves as a key ingredient in many products, too: via vinyl acetate for shoe sole foams, paints, coatings and adhesives, via purified terephthalic acid for PET bottles, as EVA film for solar panel encapsulation, and in numerous other applications. Both chemicals are thus fundamental to countless consumer goods from packaging and textiles to pharmaceuticals and construction materials that we encounter daily and that cannot be easily replaced.

EDHOX™ Process Technology

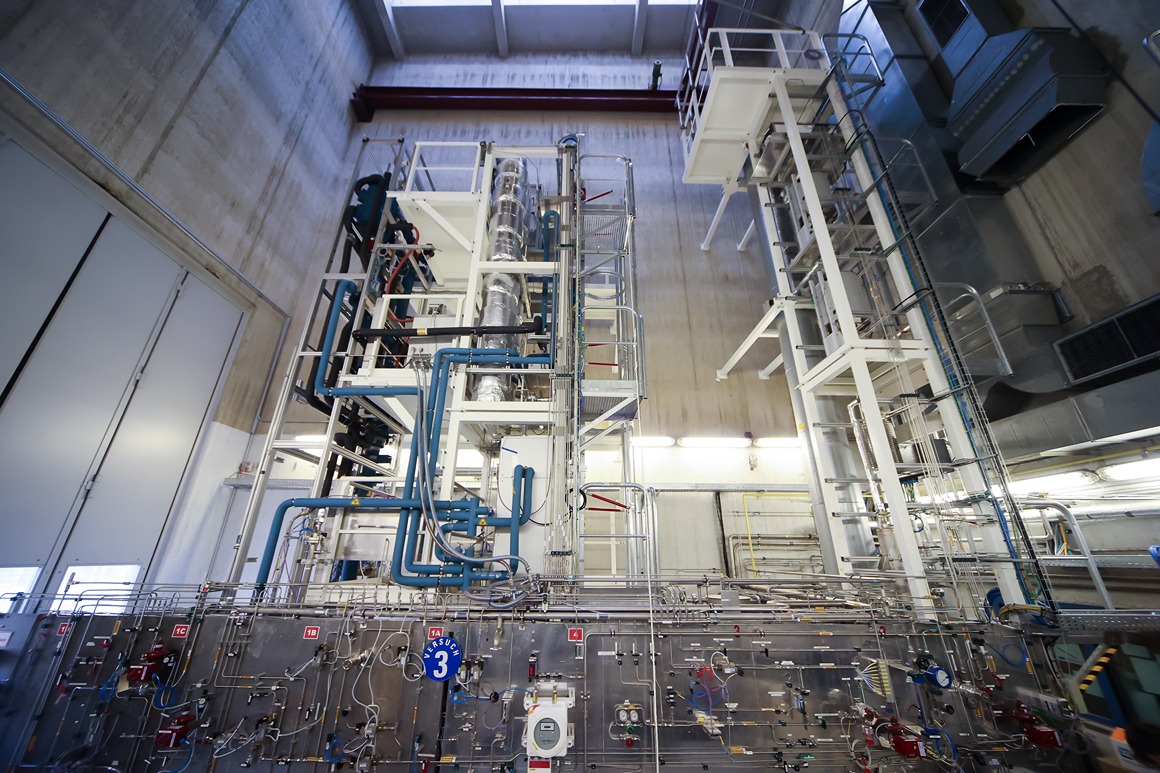

The EDHOX™ process represents a paradigm shift in chemical production. Developed through Linde's collaboration with Clariant as catalyst specialist, this innovative technology utilizes oxidative dehydrogenation (ODH) of ethane to create both ethylene and acetic acid simultaneously. In this groundbreaking process, ethane and oxygen undergo selective conversion through our heterogeneous catalyst in a multi-tubular reactor, with molten salt efficiently removing generated heat. The result: polymer-grade ethylene, glacial acetic acid, and purified carbon dioxide ready for utilization or storage.

Features and Benefits

EDHOX™ with OxyMax™ E catalyst

A transformative technology addressing sustainability, efficiency, and economic challenges simultaneously.

Reduced Scope 1 CO₂ emissions by at least 60% up to full net zero with potential for zero Scope 2 emissions when using green electricity; process fully electrified by design

Up to 70% lower energy consumption compared to conventional ethylene production

Mild operating conditions operates below 400°C vs. >1000°C for steam cracking, improving process safety and reducing equipment stress

Superior economics per ton of ethylene with 5-20% lower CAPEX requirements

Improved carbon efficiency by up to 5% generating more high-value products from the same ethane feedstock stream than conventional processes

Commercially ready technology and applicable for greenfield projects, retrofits, and downstream integration, especially VAM, PTA, EVA

OxyMax™ E and EDHOX™ Process: Sustainability by Design

Unlike traditional steam cracking that requires temperatures exceeding 1000°C, our ODH process operates below 400°C at moderate pressure, delivering remarkable sustainability benefits. The process delivers ethylene and acetic acid with substantially reduced to completely eliminated Scope 1 CO₂ emissions and can furthermore achieve zero Scope 2 emissions when powered by green or nuclear electricity. The technology requires approximately 70% less energy than conventional methods while maintaining superior carbon efficiency. As valuable co-products, EDHOX™ produces glacial acetic acid and purified CO₂.

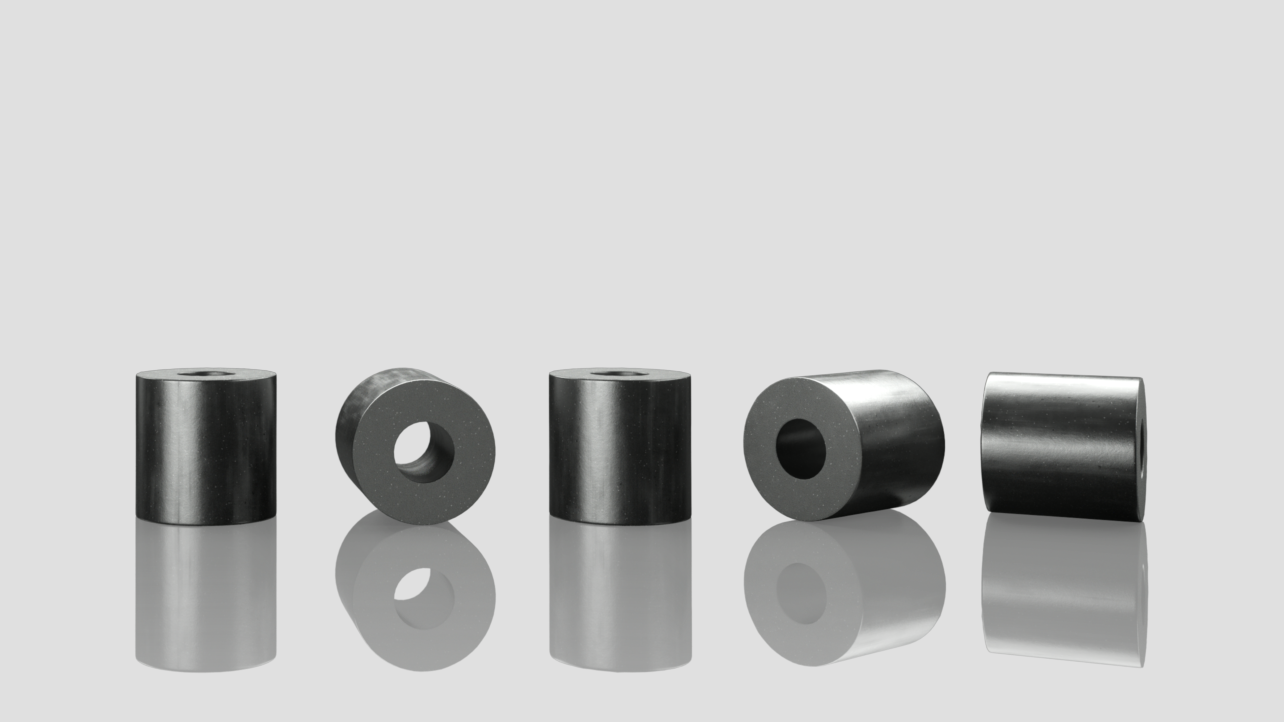

Advanced Catalyst Technology

Clariant has conducted thorough evaluation of the new catalyst’s core ingredient MoVTeNb-Oxide, assessing potential impacts on human health, the environment, and waste management. Comprehensive guidelines for safe storage, handling, transportation, and disposal have been established to ensure compliance with all relevant safety regulations and minimize hazards. In addition, the catalyst has undergone rigorous registration processes in many countries, validating its compliance with governmental standards and regulations.

Clariant's OxyMax™ catalysts offer novel chemical production technology that balances innovation with sustainability to create essential materials for everyday applications.

OxyMax™ 288: Ultra-selective oxidation catalyst

OxyMax™ 288 is a highly specialized catalyst designed to simultaneously reduce both, acetylene and oxygen, to ultra-low levels in Linde's EDHOX™ process while preserving valuable ethylene.

- In specification acetylene concentration in ethylene product

- High process safety through near-complete oxygen removal

- Minimal ethylene loss due to catalyst’s unique selectivity characteristics

- Stable performance in Linde's EDHOX™ process configurations