Our solutions for wood bonding -

PP-based performance enhancers

with renewable-based options

Boost the natural bonding power of your wood adhesives

Wood remains one of the most useful materials for making furniture and decorating living spaces, and hot melt adhesives have become a widely used option for bonding and laminating wooden parts. Besides assembly, they are used for a wide range of laminating techniques, such as flat lamination (also often called flat panel lamination), edge banding, and profile wrapping.

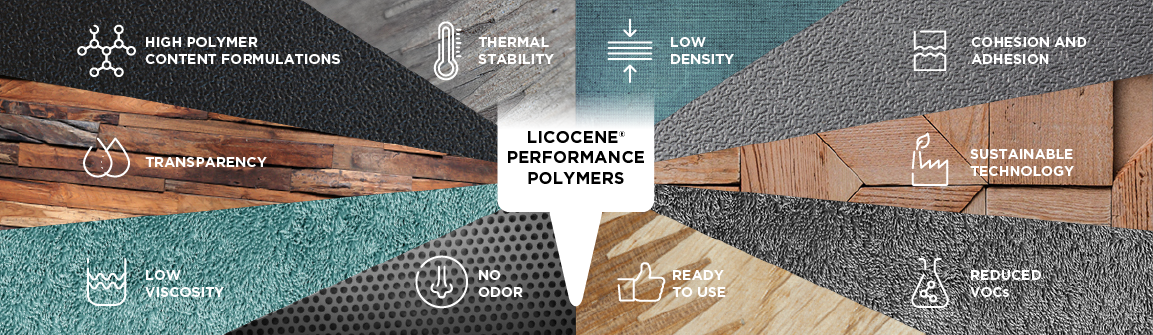

Our Licocene™ range provides a choice of PP-based polymers and waxes that can be used as performance-enhancing components in hot melt adhesive formulations for woodworking applications. For glue and furniture makers looking to spruce up the eco profile of their wood adhesives with a pared-down carbon footprint, we offer earth-friendly, renewable-based Terra versions of our products.

Watch how we innovate to improve hot melt bonding

With renewable-based solutions like our Licocene™ Terra products, we take sustainable innovation in hot-melt adhesive bonding to the next level.

Tailored solutions for improving heat resistance, adhesion power and carbon footprint

Whether amid the busy workings of a factory floor or in the Sunday quiet of a hobby room, using a high-performing wood adhesive is essential for achieving the desired results.

When serving as a component of hot melt formulations, our Licocene™ solutions can substantially enhance the heat resistance of wood bonding adhesives, enabling better performance in processes ranging from assembly and panel lamination to edge banding and profile wrapping. We also offer MAH-grafted polymers for the hazard label free boosting of adhesion properties, as well as natural-based Terra versions with identical performance to their conventionally produced counterparts.

Find out more about our solutions for hot melt bonding

Tap into a broad spectrum of bonding advantages

Three good reasons for choosing Clariant

key benefits of our Licocene™ solutions

1.Enables boosted adhesion power, strengthening bonds in assembly and lamination

2.Increased heat resistance allows end product usage at higher temperatures

3.Highly stable components enabling considerable cost-in-use savings

Stability and strength you can count on

up to °CHeat resistance

for thermally stable, trouble-free wood bonding

up to %More adhesive strength

ensuring the integrity of bonded products and laminates

≥ %Renewable carbon

making up the sustainable Terra versions of our products