Cargo Desiccants for Containerized Shipments of Rice

PROTECTION FOR MOISTURE-SENSITIVE COMMODITIES

The global trade in rice is vast, totaling more than 45 million metric tons per year. That is enough rice to fully load more 1.8 million 20-ft shipping containers with 25 metric tons of rice apiece.

In addition to China, which is by far the world’s largest rice consumer, countries in Sub-Saharan Africa (Nigeria, Cote d’Ivoire, and Egypt), the Middle East (Iran, Saudi Arabia, and Iraq), and the European Union are all major rice importers. So, at any one time, there’s a lot of rice being shipped from place to place, primarily from major growing regions in India, China, and Southeast Asia to these locations.

Today, most rice shipments consist of bagged rice (25 or 50-kg bags) stacked in sealed, 20-foot shipping containers. Before it can be shipped, however, rice must be harvested and carefully prepared. First, the rice must be dried as soon as possible to a consistent 13-14% moisture level, then bagged. After bagging, the rice must be protected from moisture, and monitored for moisture levels, before it is loaded into containers for shipping.

The Problem: Excess Moisture during Shipping

As shippers, traders, and global aid agencies know, rice and other staple grains are also highly vulnerable to damage caused by excess moisture during long shipping voyages. This is true even when it has been properly bagged, loaded and sealed into shipping containers. Why? Because any time that the surface temperature of a container drops by just 4.4 to 5.5° C (8 to 10° F) during a change in weather, all of the residual moisture within the container – in headspace air, packaging materials, dunnage, wooden pallets or container flooring—can condense into water droplets called “container rain.” Similarly, temperature drops within the container can condense moisture within the rice itself, causing a similar problem known as “cargo sweat.”

Container rain may drip down the walls, saturate protective covering materials and bags, soak the rice, or pool on the floor. Cargo sweat works its way from the rice outward, first saturating the rice—causing caking, clumping, or mold growth—and then damaging the bags. As temperatures change, condensation cycles can happen repeatedly as the dew point rises and falls, causing the air in the container or the rice to capture and then release moisture.

The Solution: Cargo Desiccants

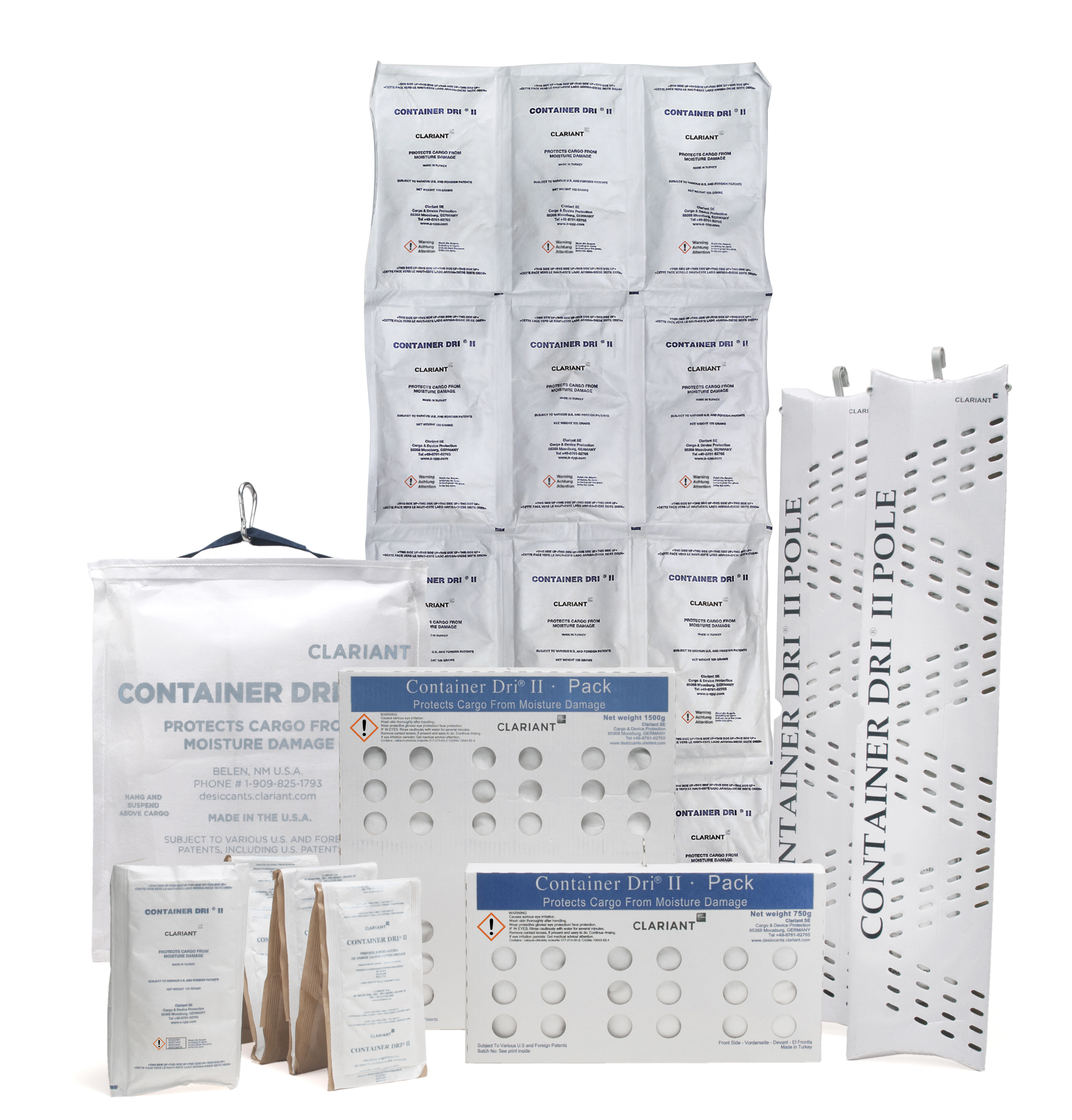

For this reason, major grain shippers require the use of cargo desiccants, which are able to absorb large amounts of moisture in sealed cargo containers and thus protect cargoes from damage. Leading shippers frequently use Container Dri® II cargo desiccants, a non-toxic, high-performance cargo desiccant from Clariant Cargo & Device Protection.

Available in bags, poles and strips that are sized for use in cargo containers, Container Dri II cargo desiccant absorbs moisture equal to 300% of its weight at a moderate level of humidity, and even more at very high levels of humidity. When used as recommended, Container Dri II desiccant protects containerized shipments of rice that must be kept at a controlled level of humidity for extended periods of time.