Our waxes for resin manufacturing & compounding

SMOOTHING YOUR PATH TO SUPERIOR POLYMERS

Enhance flow, demolding and many other properties

WITH OUR HIGH-PERFORMING WAX SOLUTIONS

With our Licowax™ and Licocene™ polymeric waxes, we offer resin manufacturers excellent additives for improving the melt and flow characteristics of their polymers. Our saponified Licomont™ montan waxes are a popular choice for nucleating polyamides and polyesters to speed up cycle times. Similarly, our specialty Ceridust™ grades can serve as gas cell nucleators in specialty foams when discrete cell structure and faster hardening times are needed.

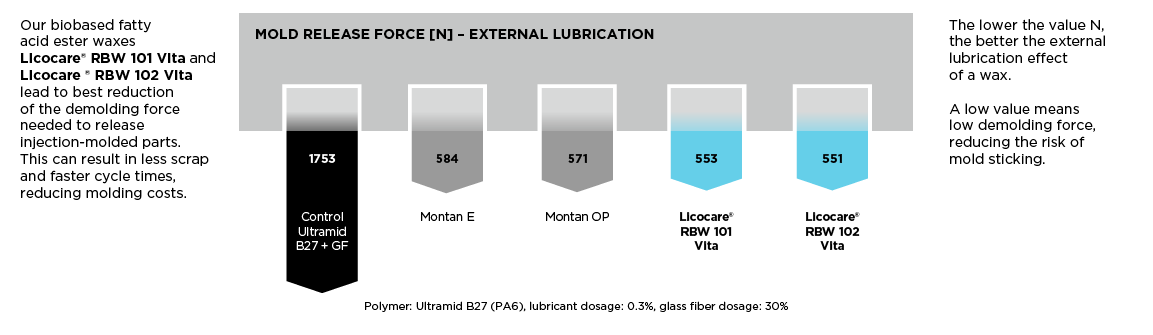

In compounding, our advanced wax additives add value to all kinds of plastic compounds. By improving polymer melt flow and the mold release of plastic parts, our Licocare™ and Licowax™ solutions enable faster cycles, smoother surfaces, better dispersion and higher shaping flexibility. For enhancing the surface and mechanical properties of thermoplastic composites, we offer tailored solutions like our MAH-grafted Licocene™.

Watch how we innovate

TO IMPROVE PLASTICS

With biobased solutions like our Licocare™ RBW Vita additives, we take the sustainable enhancement of plastics to the next level.

How our waxes help to jazz up the energy profiles of houses and cars

Proper thermal insulation is one of the most effective ways to reduce the energy needs of buildings and shrink their carbon footprint. Our high-performing gas cell nucleating agents for insulating materials such as expanded polystyrene (EPS) support this vital strategy.

To reduce fuel consumption and give e-cars greater range, the automotive industry is increasingly making vehicles lighter by replacing their metal parts with plastics. To be used on exteriors or under the hood, these often must be reinforced with fibers or fillers. With our special compatibilizers and coupling agents from the Licocene™ range, we make it easier to incorporate property-enhancing materials into polypropylene (PP) and to give it the desired mechanical characteristics.

Find out more about our solutions for resins and compounds

Experience a natural new ease

IN DEMOLDING PLASTICS

By acting as an external lubricating layer between the polymer and the hot metal surfaces of molds, wax reduces the demolding force needed to release injection-molded parts. This leads to fewer stuck parts, less scrap, less downtime and faster cycle times. On the whole, the result can be significantly lower molding costs.

Three good reasons for choosing Clariant

KEY BENEFITS OF OUR WAX SOLUTIONS

1.Enable higher operational efficiency due to faster flow at lower temperatures, reducing molding time and costs, and allowing shorter cooling times in extrusion

2.Enable enhanced performance due to easier, faster filling of molds with difficult geometries, leading to less molded-in stress, better mechanics, and less scrap

3.Provide opportunities for saving formulations costs due to the lower need for more expensive polymers and heat stabilizers

How are high-performing wax additives supporting engineering plastics compounds?

JOHNSON LYU HAS THE ANSWER

» The addition of Clariant’s wax additives to our engineering plastics enhances the performance of our compounds to meet the stringent requirements of our customers in demanding industries such as electronics or automotive. In particular, we value the growing number of highly sustainable solutions from Clariant. «

Johnson Lyu

President, Jiangsu Boiln Plastics

Sustainability and performance

YOU CAN COUNT ON

>%Renewable Carbon Index

distinguishing our biobased Licocare™ RBW Vita solutions

up to %Cycle time reduction

with our nucleating agents for polyamides and polyesters

≤%Weight loss (TGA under air)

of our Licocare™ RBW 300 Vita after 30 mins. at 300 °C