Transforming CO₂ into sustainable fuel and chemical solutions

E-methanol, also known as green methanol, is a renewable fuel and chemical feedstock produced through direct catalytic hydrogenation of biogenic CO₂ using green hydrogen. Unlike conventional methanol derived from fossil fuels, E-methanol offers a sustainable pathway to reduce carbon emissions while providing a versatile energy carrier that can be used as a fuel for maritime and long-distance road transport, as well as a feedstock for sustainable chemicals and plastics manufacturing.

Overcoming e-methanol production challenges with innovative catalysts

The production of e-methanol presents several technical challenges that Clariant’s catalyst technology effectively addresses.

CO₂ activation

Carbon dioxide’s molecular stability requires specialized high-activity catalysts capable of efficient conversion under challenging conditions.

Water Formation

The reaction between CO₂ and hydrogen produces water as a byproduct, which can deactivate traditional methanol synthesis catalysts. Clariant’s solutions maintain effectiveness and lifetime despite this challenge.

Process stability

Clariant catalysts deliver consistent performance over extended periods under the demanding and sometimes intermittent conditions of CO₂-to-methanol conversion.

Yield optimization

Our advanced catalysts maximize conversion efficiency while minimizing energy consumption, delivering commercially viable methanol yields from CO₂.

Carbon2Chem project: Transforming industrial CO₂ emissions into valuable resources

Clariant proudly participates in the Carbon2Chem project, a groundbreaking cross-industry initiative reducing industrial CO₂ emissions from steel production. Launched in 2016 with German Federal Ministry of Education and Research support, this project transforms steel production emissions into valuable chemicals like methanol.

As a project partner, Clariant provides high-performance MegaMax™ 800 methanol catalysts and specialized adsorbents for feed-gas purification at ThyssenKrupp's pilot plant. The resulting methanol serves multiple purposes in the chemical industry and functions as a low-emission fuel for sustainable transportation.

Kassø E-methanol project: MegaMax 900 operating in one of the largest commercial e-methanol plants

Clariant’s MegaMax 900 methanol synthesis catalyst successfully operates at European Energy’s E-methanol plant in Kassø, Denmark—one of the world’s first and largest commercial e-methanol facilities. The plant uses biogenic CO₂ and green hydrogen to produce up to 42,000 tons of green methanol annually, with the catalyst demonstrating excellent activity and stability despite challenging of CO2-to-methanol conversion.

The Kassø project demonstrates the commercial viability of E-methanol production the effectiveness of Clariant's catalyst technology under the challenging conditions of CO₂-to-methanol conversion.

The plant's annual production is already allocated to maritime giant Maersk for powering its first carbon-neutral fleet (namely the green methanol-powered containerships Laura Maersk and Ane Maersk), the Lego Group, and Novo Nordisk.

The Kassø project showcases how Clariant's innovative catalyst solutions enable the transition to sustainable fuels across multiple industries.

MegaMax 900 DCARB: Revolutionary CO₂ to methanol catalyst technology

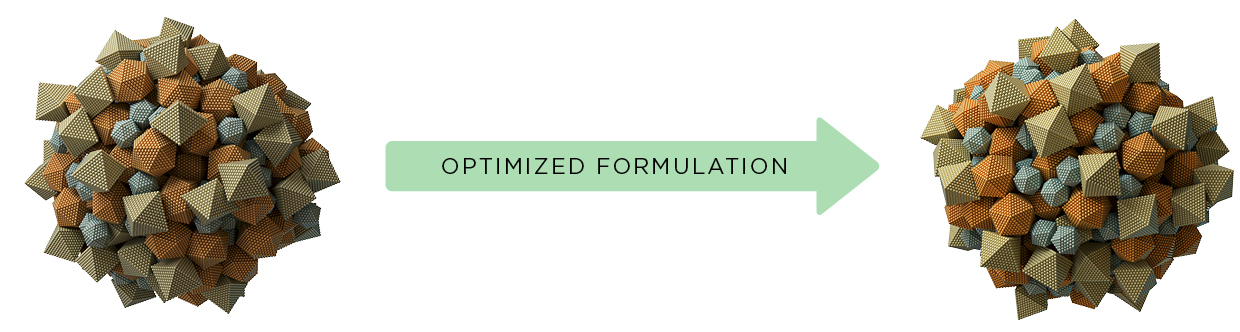

Building over 50 years of methanol synthesis expertise, Clariant developed MegaMax 900 DCARB—a breakthrough catalyst specifically engineered for direct e-methanol production from CO₂ and green hydrogen. This innovative catalyst technology transforms carbon capture into sustainable fuel solutions with remarkable efficiency.

The optimized formulation with an advanced microstructure provides exceptional physical robustness, increased number of active sites, a high turnover frequency (TOF), and an improved metal dispersion resulting in consistent, high-level performance over extended periods and higher hydrothermal stability than previous catalyst generations.

Higher activity

Superior lifetime yield

Higher mechanical stability

4 years of typical lifetime

Higher hydrothermal stability

Lower operational costs

Longer lifetime

Significant monetary benefits

Significant monetary benefits

Superior performance

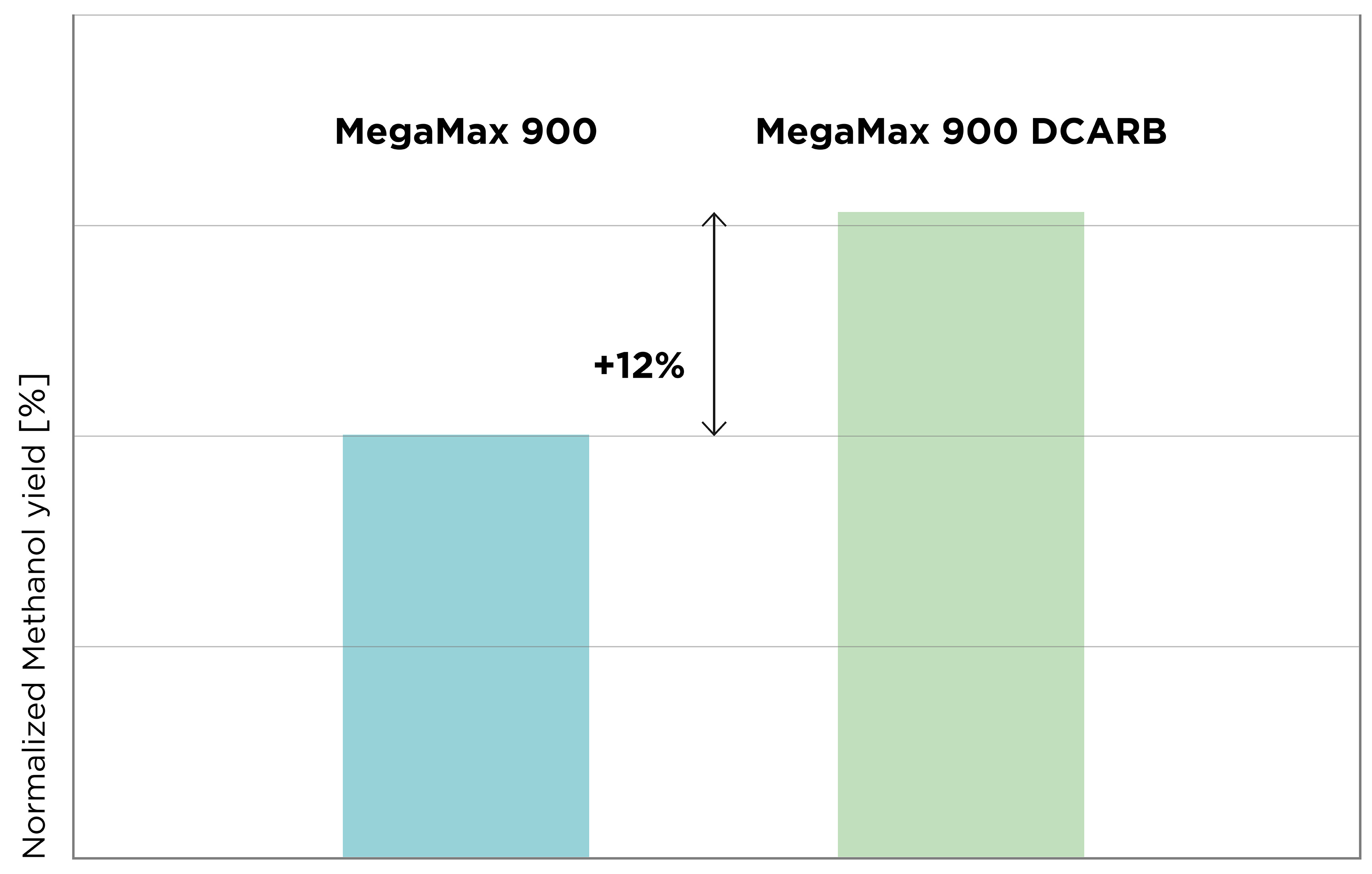

Clariant’s MegaMax 900 DCARB catalyst delivers a remarkable 12% increase in methanol yield when processing high CO₂ syngas feeds compared to previous generation catalysts. This enhanced performance ensures optimal production efficiency throughout the catalyst's entire lifecycle.

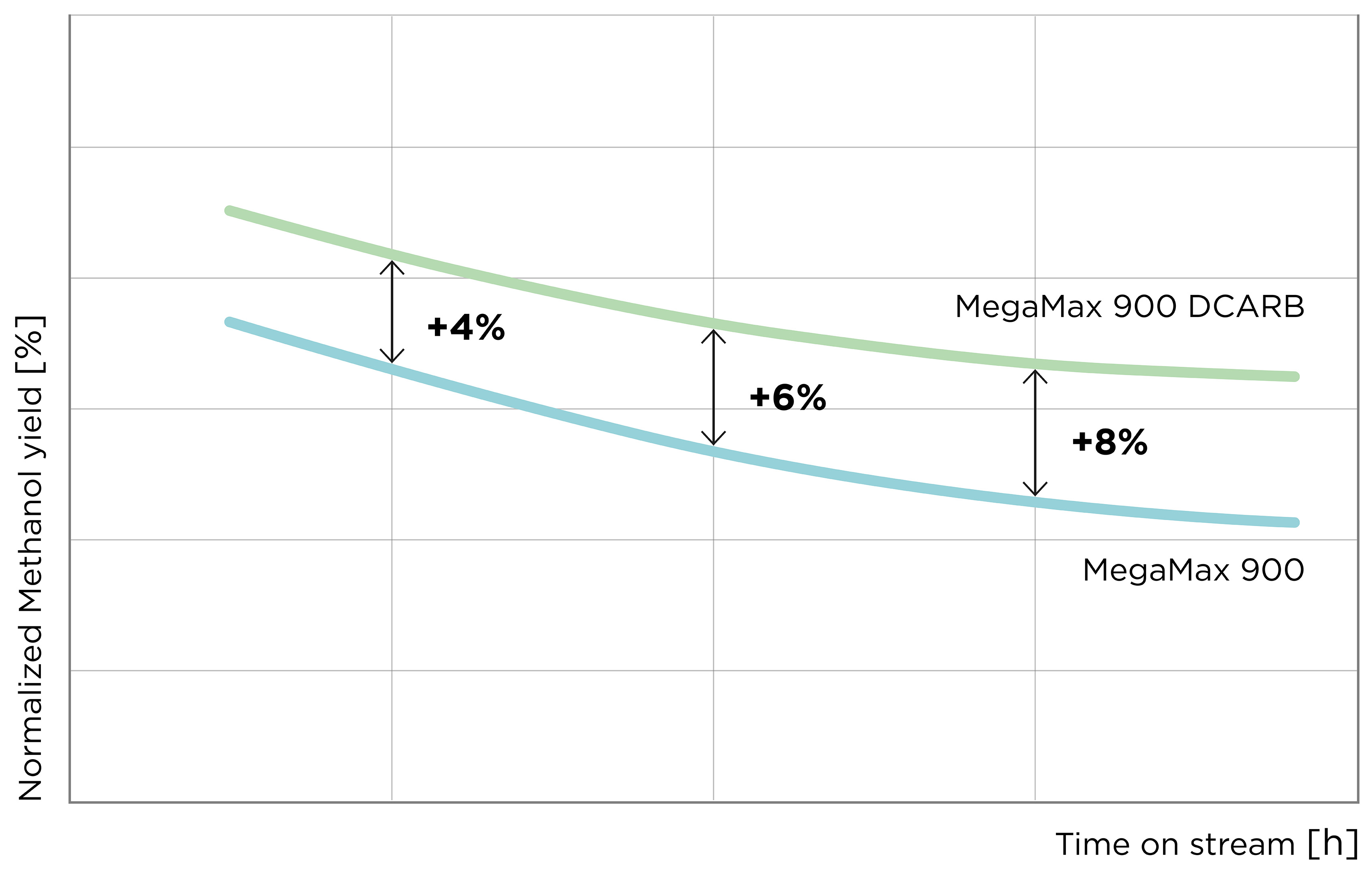

Under direct CO₂-to-methanol conversion conditions, MegaMax 900 DCARB demonstrates significantly higher activity levels than the standard MegaMax 900, making it the ideal choice for sustainable E-methanol production facilities focused on carbon utilization.

Enhanced stability

Clariant’s MegaMax 900 DCARB features an optimized microstructure that delivers exceptional physical robustness and increased active sites for consistent performance.

This specialized catalyst demonstrates superior hydrothermal stability compared to standard MegaMax 900 when processing water-rich CO₂ feedstocks.

With a typical catalyst lifetime of 4 years under CO₂-to-methanol conditions, MegaMax 900 DCARB maximizes production efficiency while reducing replacement frequency and operational downtime.

Tailor-made catalysts for CO₂ to methanol conditions

Clariant’s MegaMax 900 DCARB catalyst showcases our continuous innovation in green methanol technology. Engineered specifically for E-methanol production, it effectively solves CO₂ activation challenges and maintains performance despite water formation during reactions. With exceptional activity and proven durability, this breakthrough catalyst enables reliable commercial-scale e-methanol production, supporting the global transition to sustainable fuels and chemicals while helping industries reduce carbon footprints.

Comprehensive ACT Team Support: From Design to Operation

Clariant's Advanced Catalyst Technologies (ACT) team provides end-to-end support throughout the bio-methanol production journey.

Our experienced technical experts work closely with customers to ensure optimal catalyst performance and plant operation.

Performance prediction and process design

Our ACT team offers sophisticated performance prediction modeling to help customers optimize their process design for maximum efficiency. Using advanced simulation tools and drawing on extensive operational data, we can accurately forecast catalyst behavior under specific operating conditions, enabling informed decision-making during the planning phase.

Our technical experts use sophisticated modeling and simulation tools backed by extensive operational data to forecast catalyst behavior under specific conditions, optimizing process design for maximum efficiency.

On-site technical services

Clariant delivers more than just superior catalysts—we provide complete production support through:

- Expert Catalyst Loading: Our specialists ensure precise installation using proven techniques that maximize catalyst effectiveness and minimize pressure drop.

- Controlled Catalyst Reduction: Our team carefully monitors this crucial activation process to achieve optimal catalyst performance from the start.

- Start-up Monitoring: During this critical phase, our experts provide on-site guidance to ensure smooth operation and fine-tune parameters for peak performance.

Ongoing Technical Support

Throughout the catalyst lifecycle, our ACT team remains available for troubleshooting, performance optimization, and technical consultation.

Digital services

CLARITY Digital Platform: Our innovative tool transforms plant data into actionable insights at the click of a button, optimizing efficiency and profitability.