Advancing plastic circularity through high-performance materials

Plastic waste is typically incinerated or disposed of in landfills, contributing to the increasing strain on the environment. In contrast, chemical recycling of plastic waste converts it into pyrolysis oils, which can be used to produce valuable chemicals. The challenge, however, is that the process involves a variety of plastics and fluctuating contaminants.

Clariant offers a powerful solution for pyrolysis oil purification: HDMax™ catalysts and CLARIT™ adsorbents. Regardless of process configuration or plastic waste feedstock, our adaptable products ensure highly effective purification to remove a broad range of contaminants at low total cost of ownership.

Advancing plastic circularity through high-performance materials

Plastic waste is typically incinerated or disposed of in landfills, contributing to the increasing strain on the environment. In contrast, chemical recycling of plastic waste converts it into pyrolysis oils, which can be used to produce valuable chemicals. The challenge, however, is that the process involves a variety of plastics and fluctuating contaminants.

Clariant offers a powerful solution for pyrolysis oil purification: HDMax™ catalysts and CLARIT™ adsorbents. Regardless of process configuration or plastic waste feedstock, our adaptable products ensure highly effective purification to remove a broad range of contaminants at low total cost of ownership.

Clariant's innovative plastics recycling solution

Plastic waste is a massive global concern, but Clariant has an innovative solution contributing to solve the issue! Billions of tons of plastic have piled up, with recycling facing challenges like contamination. Don't miss this video showcasing Clariant's Adaptable PyOil Upgrading technology - it's transforming chemical plastics recycling. See how our innovations are making a real difference in creating a sustainable future from plastic waste. Get inspired by clicking play!

Clariant's innovative plastics recycling solution

Plastic waste is a massive global concern, but Clariant has an innovative solution contributing to solve the issue! Billions of tons of plastic have piled up, with recycling facing challenges like contamination. Don't miss this video showcasing Clariant's Adaptable PyOil Upgrading technology - it's transforming chemical plastics recycling. See how our innovations are making a real difference in creating a sustainable future from plastic waste. Get inspired by clicking play!

CLARIT Pyrolyze: Custom catalysts for enhanced pyrolysis

Unlock the full potential of plastic waste conversion with Clariant’s innovative pyrolysis technology. CLARIT Pyrolyze catalysts allow operation at lower temperatures, offer tailored product distribution, and enable in-situ impurity mitigation, resulting in cleaner output streams. Leverage our expertise in catalysis and pyrolysis to optimize your plastic waste valorization and advance your contribution to a circular economy.

CLARIT Protect: Stabilization & purification adsorbents for optimized pyoil quality

Maximize the value of your pyrolysis oil (pyoil) streams with CLARIT Protect, Clariant's cutting-edge stabilization and purification technologies. Our innovative stabilization technologies ensure safe transportation and extended storage life to prevent corrosion and maintain product integrity throughout the supply chain.

Besides stabilization, our regenerable adsorbents also offer a sustainable, cost-effective approach to pyoil purification. By removing contaminants and impurities, you can optimize the quality of pyoil streams while minimizing operational expenses and environmental impact.

Our short-term solution enables impurity reduction and stabilization of pyrolysis oils at production sites through a simple, cost-effective adsorption step - an ideal option to increase co-feeding rates into steam crackers.

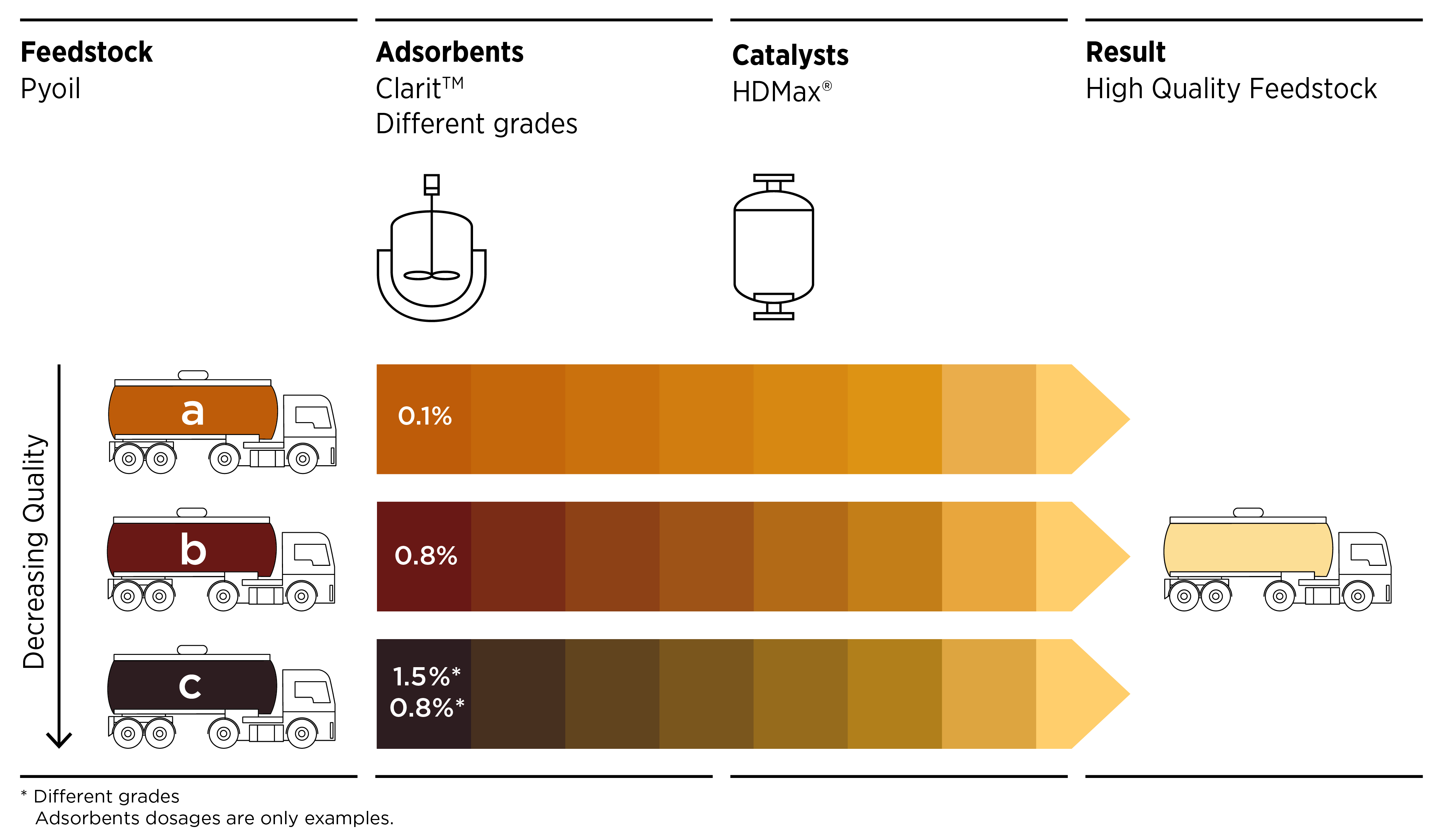

Adaptable PyOil upgrading enabling economical cracker-compatibility

Adaptable PyOil upgrading strengths

Feedstock

- Broaden the scope: high (a) to low quality (c)

Clarit adsorbents

- Adaptable choice of material: high acceptance level of incoming quality

- Adaptable dosage: minimization of spent material and costs

HDMax catalysts

- No gum formation

- Selective phosphorous and silicon removal

- Adaptable hydrogenation deepness

Result

- High quality product

- Steam-cracker compatible

- Achieved from different pyoil qualities

Long-term high-quality product

Our long-term solution enables upgrading of pyrolysis oils through a cost-optimized combination of adsorption and hydrogenation steps - an ideal option to fully match steam cracker specifications.

Our contribution to a more circular plastics economy

Clariant is solving the challenges of pyrolysis oil purification with its new HDMax™ catalysts and ClaritTM adsorbents. The powerful, adaptable solution is specially developed for removing a wide range of impurities from pyrolysis oil, regardless of process configuration or plastic waste feedstock. Used together, the adsorbents extend the lifetime of the catalysts. The complementary products ensure highly effective removal of a broad range of contaminants, such as metals, chlorine, nitrogen, oxygenates, silicon and phosphorous.

This allows flexible, cost-efficient production of pyrolysis oil that is compatible with steam crackers. Our comprehensive solution includes operational support throughout the lifetime of our products to ensure optimum performance and results.

What are your benefits?

The combination gives producers greater flexibility regardless of feedstock changes or process configuration. Our broad portfolio also allows us to offer customized solutions to suit a variety of requirements. Overall, producers can process larger volumes of pyrolysis oil of higher quality at lower costs.

Plastic waste feedstock flexibility

Improved pyrolysis efficiency

Highly efficient impurity removal

Cracker compatible pyrolysis oil

Higher yields at lower operating costs

How Clariant’s products support the transition towards higher recycling rates

Clarit series and adsorbents

- 1 Mio tons of minerals mined every year

- More than 100 years' experience in purification of ever-changing feedstocks (e.g. edible oils, oils & fats like UCOs for fuel production)

- Production in 14 countries at 25 sites

- Serving customers in 110 countries

- Decades of technical edible oil purification and renewable fuels applied for pyrolysis oil purification

HDMax series hydrogenation catalysts

- Demonstrated performance for upgrading of complex crude oil fractions and intermediates towards fuel and high value hydrocarbon products

- Series designed for various challenging feedstocks

- Offered with base- and precious-metal functionalities, adapted to feedstock quality and product specifications

- Low pressure drop & high mechanical strength

- Operating experience with hydrogenation and HDMax series since 1950s

Clariant Adsorbents

Want to know more about Clarit?

Get in contact with Vinicius

Clariant Catalysts

Want to know more about HDMax?

Get in contact with Séval