Methanol Synthesis - Increasing plant efficiency and lifetime productivity

Methanol is an important platform molecule for chemicals and energy. Not only is it a C1 building block for base chemicals (e.g. formaldehyde), but also a starting material for innovative processes like methanol to olefin (MTO) and methanol to propylene (MTP). Furthermore, methanol has clearly arrived in the energy sector, and plays an increasingly important role in fuel blending, ship fuel, methanol to gasoline (MTG), power to methanol (PTM), and other projects addressing the general need for higher sustainability.

Clariant has been developing, producing, and marketing highly active and selective catalysts for methanol production for well over 50 years, continuously improving catalyst performance to serve changing market needs.

We offer a complete range of methanol synthesis catalysts and technologies and support you with comprehensive technical services to ensure their optimal performance. Our customers benefit from higher lifetime productivity, lower by-product formation, and reduced feedstock and energy consumption.

Since the early 1970s, Air Liquide Engineering & Construction and Clariant Catalysts have been in a strategic collaboration, which has led to many innovations over the last 50 years. Our close partnership allows us to offer customers turnkey solutions for highly efficient methanol production.

Clariant’s portfolio of methanol process catalysts also include:

- ActiSorb™ series adsorbents and HDMax™ catalystsfor feed purification

- ReforMax™ series catalysts for pre-reforming, steam methane reforming and autothermal reforming

Our Portfolio

Methanol Synthesis

Green methanol: powering the sustainable energy transition

Green methanol

Green methanol is rapidly emerging as a cornerstone solution in the global energy transition, offering a renewable and sustainable alternative to conventional fossil-based methanol. As a versatile liquid energy carrier, green methanol is projected to experience substantial growth over the next two decades, creating viable decarbonization pathways across multiple industries.

Our ReforSafE services

OUR EYE INSIDE YOUR FURNACE

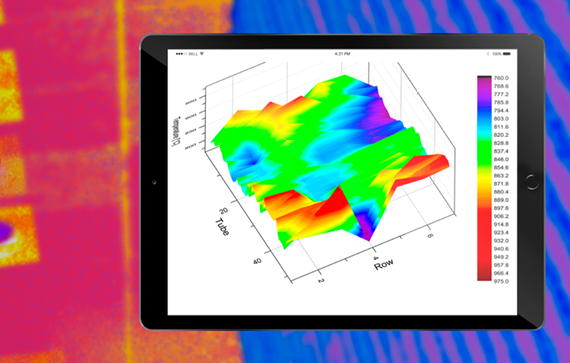

Clariant Catalysts provides high-tech monitoring and catalyst solutions to help Syngas plants to perform at their full potential to be competitive. Our ReforSafETM is an advanced technical service solution for a comprehensive reformer survey and performance optimization.