Clariant Oil Services Increases Production of Lazy Gas Wells by 1419.8 Mscfd

Benefits

- Increase in gas production from 30 e3m3 (1064.8 Mscfd) to 70 e3m3 (2484.6 Mscfd) per day

- Successful removal of water and solids that were blocking the perforated interval

- The increase in production coupled with a very low associated chemical cost added significant value

Background

Low pressure gas wells can be dramatically affected by the production of water – either by free produced water or condensation water caused by the cooling of gas as it travels up the production tubing. When water collects in the bottom of a well, it can lead to lost production. And if allowed to build up to sufficient levels, it will kill production altogether. When solid soap sticks or liquid foamers are added to the water column, betaines, sulfonates (fluoro-surfactants for condensate foaming), etc. and a persistent foam is formed, thus lightening the hydrostatic head and enabling regular gas production to lift the water from the well.

The wells on this Alberta lease were particularly sensitive to water production, as pressure less than 700 kPa (102 psi) and production of only 0.5m3 (3.15 bls/d) of water per day would kill the well. Well depth ranged from 500 to 750 meters (1650 to 2460 feet).

Additional challenges arose when a high amount of solids further loaded up the wells and lowered production, and when asphaltene precipitation reacted with the sand production to form a very adherent and dense solid precipitate downhole.

Clariant Oil Services Solutions and Value Delivered

Clariant Oil Services initially cleaned the wells with a batch treatment of asphaltene solvent (WellBoost™ 115* and WellBoost 131**), after which WellBoost 109*** was used to unload solids from the well. Injection via a downhole capillary of 20 liters per day of the liquid-based foaming chemical WellBoost 108**** was then used to continually unload water and significantly increase gas production.

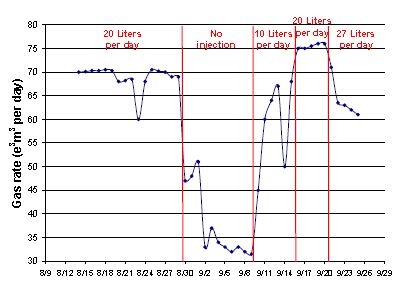

The chart below shows an optimization exercise. It illustrates that with no chemical injection, the gas rates were as low as 30 e3m3 per day (1064.8 Mscfd). When 10 liters per day of WellBoost 108 was injected, production increased to 60 e3m3 per day (2129.6 Mscfd); with 20 liters per day, production increased even more. Significant value was added by increasing production by 40 e3m3 (1419.7 Mscfd) with less than CDN$200 of associated chemical costs.

This information corresponds to the present state of our knowledge and is intended as a general description of our products and their possible applications. Clariant makes no warranties, express or implied, as to the information’s accuracy, adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use of this information. Any user of this product is responsible for determining the suitability of Clariant's products for its particular application.*Nothing included in this information waives any of Clariant’s General Terms and Conditions of Sale, which control unless it agrees otherwise in writing. Any existing intellectual/industrial property rights must be observed. Due to possible changes in our products and applicable national and international regulations and laws, the status of our products could change. Material Safety Data Sheets providing safety precautions, that should be observed when handling or storing Clariant products, are available upon request and are provided in compliance with applicable law. You should obtain and review the applicable Material Safety Data Sheet information before handling any of these products. For additional information, please contact Clariant.

*For sales to customers located within the United States and Canada the following applies in addition: NO EXPRESS OR IMPLIED WARRANTY IS MADE OF THE MERCHANTABILITY, SUITABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE OF ANY PRODUCT OR SERVICE.

™ Trademark application filed in many countries by Clariant

* Previously sold as as SOLVTREAT™ EFI-204

** Previously sold as SOLVTREAT™ 8558

*** Previously sold as SURFTREAT™ SFTW 4558

**** Previously sold as SURFTREAT™ 8553