SCALETREAT 852ND Inhibits Scale and Maximizes Value for GoM Operator

Benefits

- Successful prevention of scale deposits ensures sustainable flow assurance

- Field application prevented the need for frequent plant shut-downs to remove scale build-up in strainers and heat exchangers

- Increase in overall plant efficiency and operator revenue

- No further process upsets since treatment began

Background

A major producer in the Mississippi Canyon area of the Gulf of Mexico was experiencing severe scale build-up in the process plant. The field is located in nearly 2,000 meters (6,000 feet) of water, where several wet tree wells flow to a floating production system. The reservoir temperature is 250°F, and the topside facilities‘ average processing temperature is 135°F.

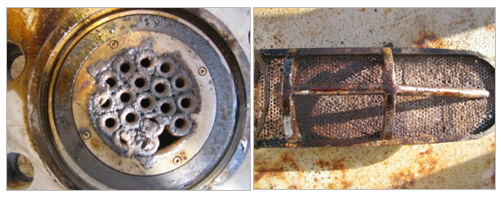

Severe scale deposition was occurring in the heat exchangers and strainers in the processing facility, causing unplanned shut-downs every month for cleaning. This resulted in production losses and decreased earnings for the operator. Images of the scale build-up are shown below.

Clariant Oil Services Solutions and Value Delivered

After a thorough review and system analysis, Clariant Oil Services deployed the polymeric scale inhibitor SCALETREAT 852ND to meet all of the operator’s requirements. Laboratory tests indicated an initial treatment of SCALETREAT 852ND to be 20 ppm, injected continuously into the inlet of the Low Pressure Inlet Separator.

Injection commenced after a scale removal operation and all routine inspections showed no discernable scale build-up, as seen below.

Application of SCALETREAT 852ND provided substantial value to the operator by negating shut down and manual cleaning interventions. The monthly shut downs incurred an annual production loss of 7,000 bbl of oil plus the associated cost of performing the intervention with a specialized cleaning crew. This increased overall plant efficiency and profitability, with minimal additional operating cost associated with the chemical.

This information corresponds to the present state of our knowledge and is intended as a general description of our products and their possible applications. Clariant makes no warranties, express or implied, as to the information’s accuracy, adequacy, sufficiency or freedom from defect and assumes no liability in connection with any use of this information. Any user of this product is responsible for determining the suitability of Clariant's products for its particular application.*Nothing included in this information waives any of Clariant’s General Terms and Conditions of Sale, which control unless it agrees otherwise in writing. Any existing intellectual/industrial property rights must be observed. Due to possible changes in our products and applicable national and international regulations and laws, the status of our products could change. Material Safety Data Sheets providing safety precautions, that should be observed when handling or storing Clariant products, are available upon request and are provided in compliance with applicable law. You should obtain and review the applicable Material Safety Data Sheet information before handling any of these products. For additional information, please contact Clariant.

*For sales to customers located within the United States and Canada the following applies in addition: NO EXPRESS OR IMPLIED WARRANTY IS MADE OF THE MERCHANTABILITY, SUITABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE OF ANY PRODUCT OR SERVICE.

Copyright © Clariant International Ltd, 2014.