Clariant Oil Services Maximizes Oil Production in Southern Alberta, Canada

Benefits

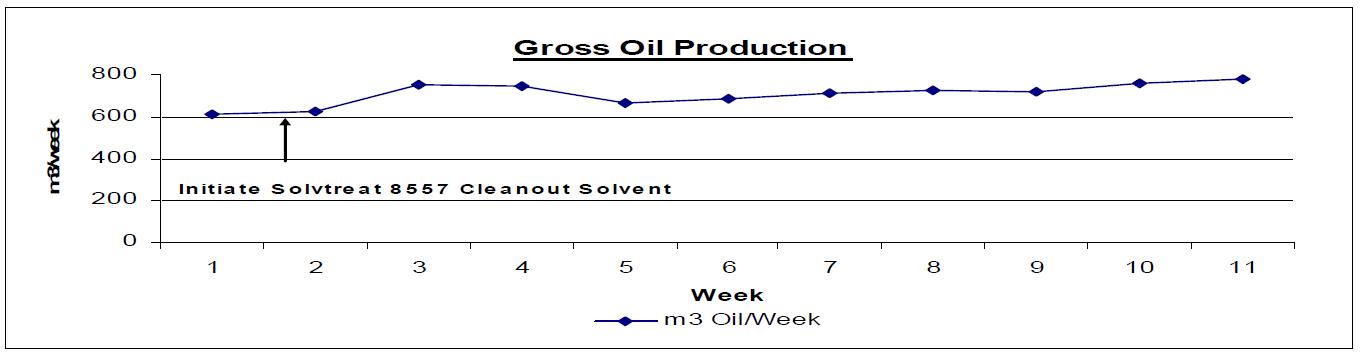

- Effective use of SOLVTREAT 8557 increased oil production by removal of paraffin and asphaltene deposits

- Initial soak treatment of only 3 to 4 hours applied at the wellbore removed blockages right through to the flowline

Background

Formation plugging from heavy hydrocarbon deposition and / or hot oiling damage was a major obstacle for an oil producer in Southern Alberta, Canada. Crude oil containing a high paraffin and asphaltene content created reduced in-flow and lower production rates.

Clariant Oil Services Solutions and Value Delivered

Clariant Oil Services performed downhole batch clean-outs in combination with formation squeezes, utilizing a clean-out solvent that would contact the perforations and formation face. The treatment volume was allowed to soak for 3 to 4 hours to solubilize any heavy hydrocarbons in the wellbore area. The product utilized was SOLVTREAT 8557, a clean-out solvent and synergistic blend of high-grade solvents specifically designed for the removal of wax and asphaltene deposits.

The removal of the organic deposition and preferential substrate wetting resulted in an increase in the relative permeability of the formation to hydrocarbon, thus improving productivity of the field.

Figure 1 illustrates the field production performance following the treatment.