Carbon Capture & Utilization (CCU)

Crossing out emissions with Power-to-X catalysts

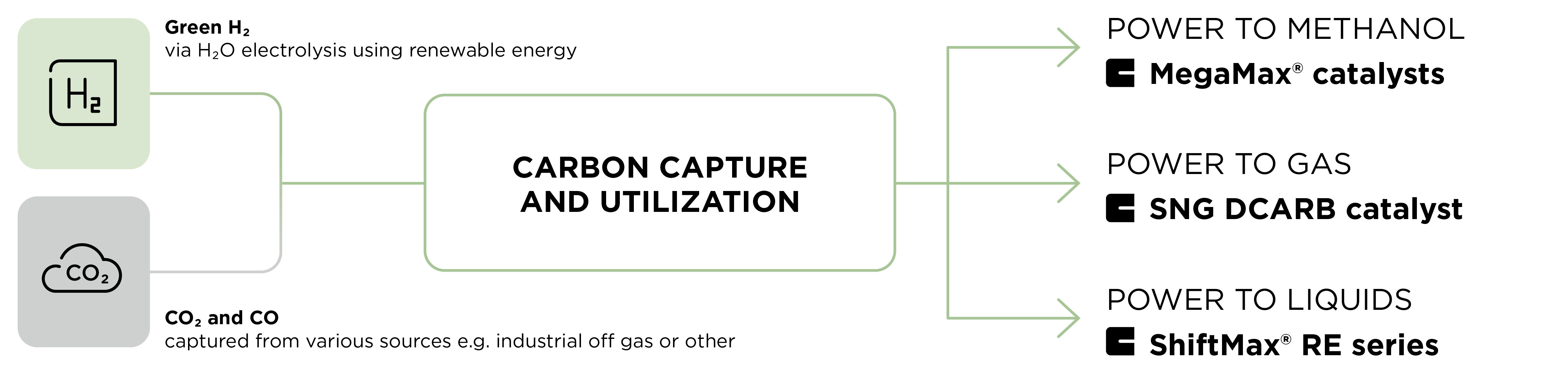

Carbon capture and utilization (CCU) is a powerful path to the decarbonization of industry and transport, either by taking advantage to utilize CO2 as an alternative feedstock for conversion into valuable products or using biogenic carbon captured from biological process or directly from the atmosphere. A rapidly developing application of CCU is Power-to-X, which uses power from renewable sources, such as solar, hydro or wind energy, to convert water into green hydrogen. The hydrogen can be utilized directly to decarbonize industrial processes or it can be further reacted with carbon dioxide, or nitrogen from air to produce a variety of fuels and chemicals.

Clariant’s CO₂ conversion technologies for power-to-x

Clariant Catalysts’ contributions to Power-to-X

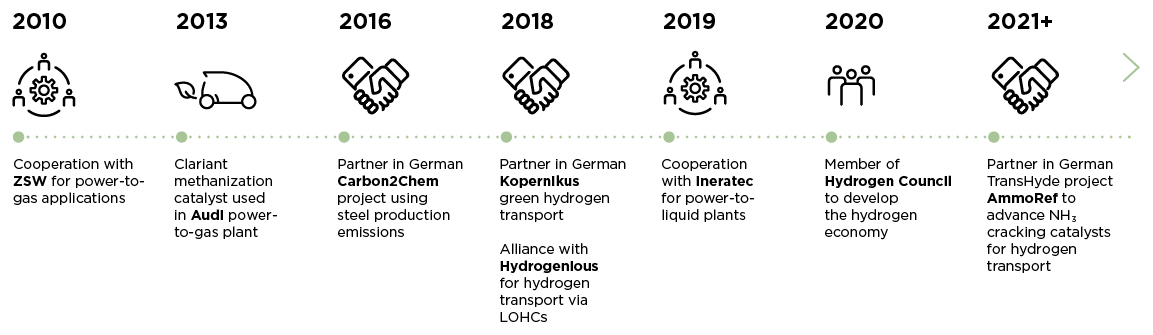

Clariant Catalysts has been supporting Power-to-X technologies for over a decade, collaborating in over 40 private and public projects. We have developed several innovative catalysts for CO₂ conversion in Power-to-X applications, including those to produce green methanol, carbon neutral SNG, and renewable hydrocarbons such as Sustainable Aviation Fuels (SAFs).

Power to Methanol

Process

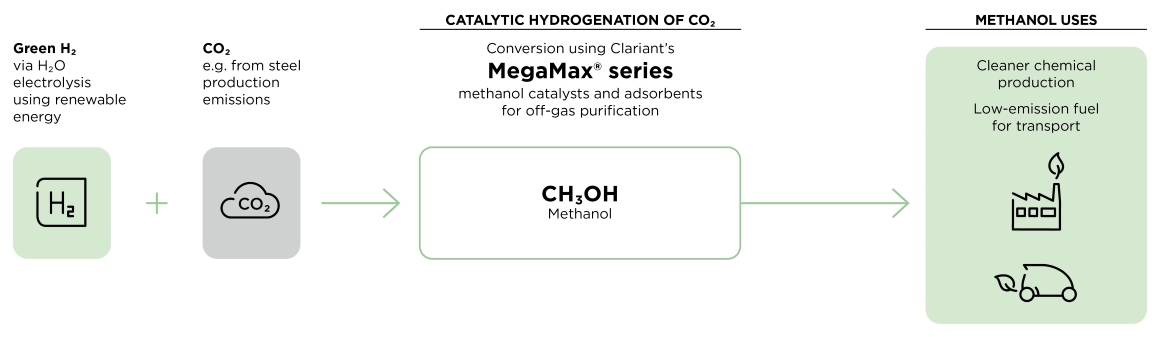

In power-to-methanol technologies, methanol is produced through direct catalytic hydrogenation of CO2. The methanol serves as a platform molecule, meaning that it can either be used as a fuel, or further converted to manufacture chemicals and plastics. Clariant offers its state-of-the-art MegaMax™ methanol catalysts for CO2 conversion, and highly efficient adsorbents for feed gas purification, which have already demonstrated their excellent suitability and performance in power-to-methanol applications.

Catalyst

MegaMax™ series are high-performance catalysts for methanol synthesis with superior efficiency, productivity, and stability. These features make the catalysts the optimal solution for projects to convert CO2 to methanol.

- Superior activity and selectivity

- Robust performance in variable operation conditions

- Outstanding stability and poison tolerance

- Increased lifetime productivity

- Improved energy efficiency

- Compatible with various methanol technologies

Projects

Sponsored by the German Federal Ministry of Education and Research, the Carbon2Chem project focuses on transforming CO2 emitted from steel production into valuable chemicals, such as methanol.

As a project partner, Clariant provides its high-performance MegaMax™ 800 methanol catalysts, as well as special adsorbents for feed-gas purification to ThyssenKrupp’s pilot plant. The methanol obtained is used for many purposes in the chemical industry and can serve as low-emission fuel for more sustainable modes or transport.

Power to Fuels

Process

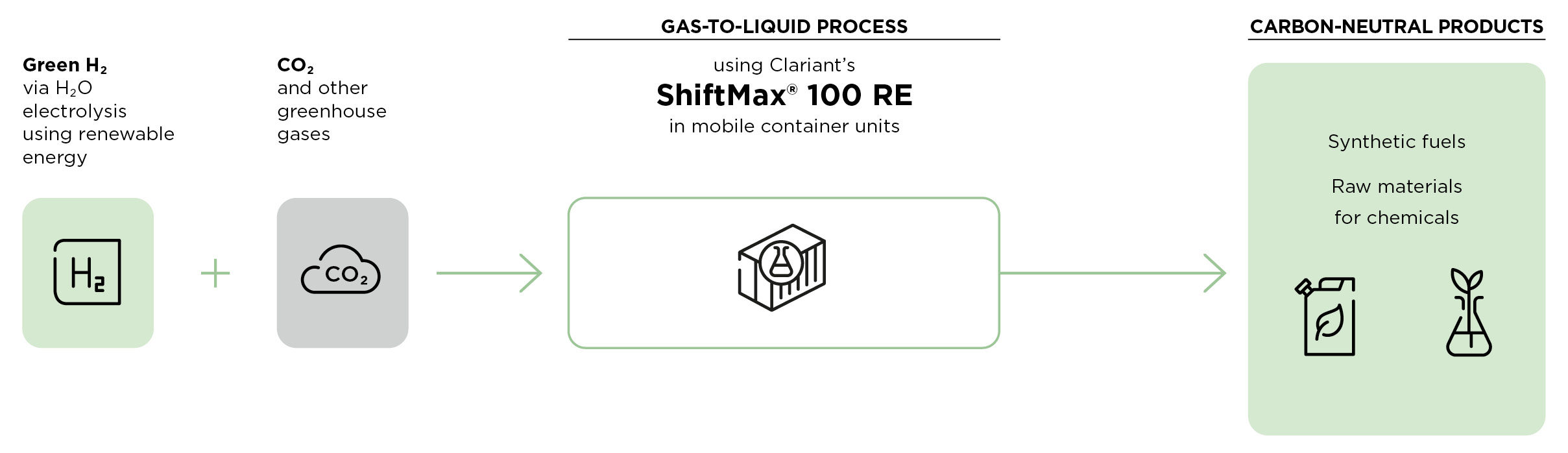

As it has become clear that biofuels alone will not be sufficient for future demands, there is increasing interest in e-fuels through power-to-liquid technologies. The method is based on the conversion of renewable hydrogen and carbon emissions into liquid fuels that possess the high energy density needed for long-distance transportation. The conversion is most often achieved through reverse water gas shift (RWGS) to generate renewable syngas, followed by Fischer-Tropsch reaction to long chain hydrocarbons. Clariant’s ShiftMax™ 100 RE catalyst has been proven in the critical RWGS step where it demonstrates excellent performance in Ineratec’s highly innovative power-to-liquid process

ShiftMax™ 100 RE high temperature catalyst for reverse water-gas-shift reactions

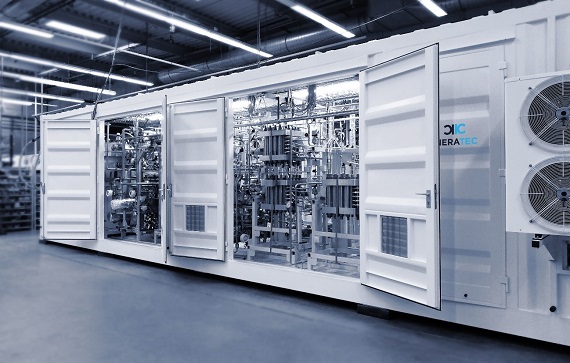

Ineratec demonstration plant (Photo © Ineratec)

Catalyst

Clariant’s high-performance catalysts for power-to-liquid applications include:

- ShiftMax™ 100 RE catalyst is used to convert green hydrogen and CO2 into renewable syngas via the reverse water-gas-shift reaction.

Projects

Ineratec is specialized in producing sustainable fuels and chemicals entirely in transportable containers. The gas-to-liquid process combines »green« hydrogen with greenhouse gases, like carbon dioxide, to form low-carbon synthetic hydrocarbons and fuels.

As a strategic partner, Clariant provides its extensive catalysis expertise and broad portfolio of syngas conditioning and upgrading catalysts to support Ineratec’s groundbreaking gas-to-liquid technology.

Power to Gas

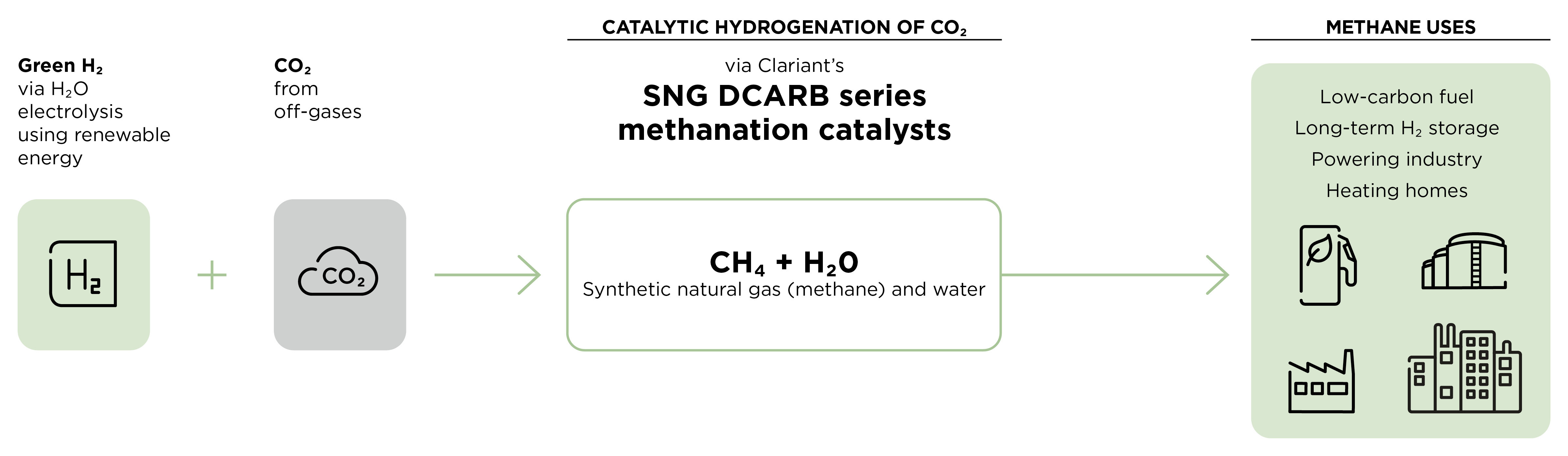

Process

Power-to-gas technology is mostly used for the production of methane. The synthetic natural gas is not only ideal as a low-carbon fuel but can also be fed into existing gas grids to power industrial plants and heat homes helping to decarbonize legacy infrastructure. Moreover, methane allows long-term storage of renewable energy using the extensive existing natural gas network. Clariant’s methanation catalysts are successfully used in power-to-methane applications to produce highly pure renewable methane, for example, in Audi’s ground-breaking e-gas plant.

Catalyst

Clariant’s SNG 100 DCARB methanation catalyst for power-to-gas processes is designed to enable highly efficient hydrogenation of CO2. Depending on the reactor technology used, methane yields of up to 99% can be achieved.

Projects

One of the earliest examples of power-to-gas technology was Audi’s e-gas plant in Werlte, Germany, which was constructed by Etogas, and relies on Clariant’s methanation catalyst. The power-to-gas facility is designed to produce renewable synthetic methane from hydrogen and carbon dioxide emissions to achieve low-carbon mobility for Audi’s A3 Sportback g-tron vehicles.