How desiccants can help prevent rust and corrosion

FOR AUTOMOTIVE PARTS DURING SHIPPING AND STORAGE

In the global auto industry, it is common for parts to be designed in one location, manufactured in another and packaged and shipped to a third for final assembly or storage. In some cases, these locations are relatively close, perhaps even in the same country. But in many other cases, parts manufacturing and final assembly operations may be thousands of miles apart, necessitating large, containerized shipments across continents or oceans.

Long-haul shipments like these can be exposed to huge swings in the temperature and humidity of air that surrounds the packaged or large automotive parts inside the containerized cargo. A rapid temperature drop of 8 to 10° C (14-20° F) can cause residual moisture in ambient air, packaging materials, or even wooden container floors to condense rapidly inside a container, resulting in “container rain”. Moisture-sensitive parts, in particular ferrous metals, are vulnerable since relative humidity levels of 40% or more can trigger surface rust. Repeated warm-cool weather cycles only intensify the risk of damage, exposing parts to high humidity or actual water droplets again and again.

Incorporating desiccants such as Desi Pak® bentonite clay desiccants and Container Dri® II container desiccants into the packaging and shipping regimen can help manufacturers, and shippers prevent moisture damage until final assembly.

Desi Pak® bentonite clay desiccants provide a simple, dependable and economical solution for reducing or preventing moisture damage in enclosed packages. Placed within a sealed package or container, Desi Pak will protect any number of products, including automotive parts, metal parts, large machinery, to cartons of food. Desi Pak bentonite clay desiccant is produced from a naturally occurring mineral activated by heat. Further, Desi Pak desiccants are noncorrosive, neutral and inert, and remain free-flowing at full adsorption.

By using Desi Pak, the relative humidity can be reduced below 40% r.h. inside the packaging and therefore offer reliable protection against corrosion, rust and other moisture damages.

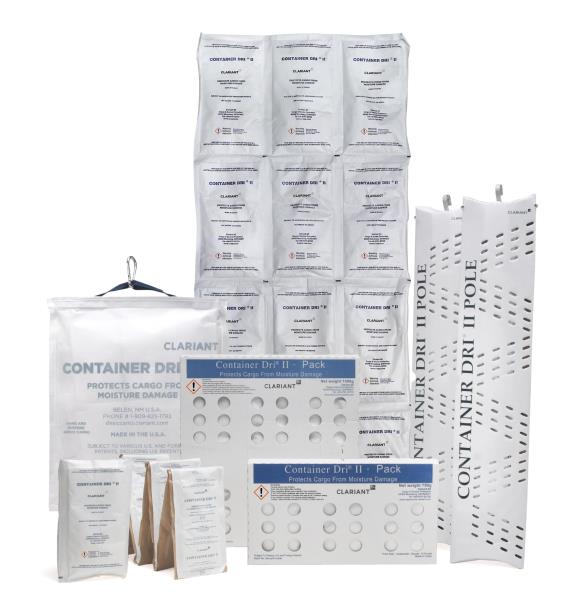

For container shipments of automotive parts, Container Dri® II helps to protect shipments of valuable metal parts from damage due to excess moisture or “container rain.” When used in containers in the form of bags, strips, poles or blankets, it absorbs excess moisture and traps it in a thick, no-spill gel. The drying action of Container Dri II maintains the relative humidity of the air below 40% regardless of temperature, keeping it well below the “dew point,” the temperature-specific level at which moisture condenses and container rain takes place. When used as recommended, it provides cost-effective moisture protection for containerized goods throughout even long-duration shipments.

Container Dri II desiccant, blend of calcium chloride and starch, is uniquely suited to the job of protecting metal parts shipments for several reasons:

- Container Dri II can absorb far more moisture, pound for pound, than any other desiccant—up to 300% percent of its own weight.

- It works gradually, continuously—when it is needed most. Container Dri II absorbs most aggressively when humidity levels are highest and less when humidity levels are lower, making it an excellent choice for large, long-duration shipments.

To learn more, visit www.clariant.com/desiccants or call us.