Our solutions for the E&E industry -

keeping our smart new world from catching fire

Halogen-free flame retardants for safeguarding the flow of currents and information

Like metals and silicon, plastics have become vital materials of the information age. In smart houses, electric cars and countless useful devices, they support circuits, insulate currents and provide light, tough casings and housings. To do so safely and fulfill relevant standards, they have to be protected with flame retardants.

Our offering of Exolit™ flame retardants for the electrical and electronics industry is just as varied and advanced as their applications. From simple switches to micro-sized assemblies, we help protecting E&E components with halogen-free, sustainable fire safety solutions that light the way to innovation.

Better and safer protection for smarter and smaller gadgets

As component density in E&E products grows, so does the risk of fire-causing short circuits. We offer flame retardant solutions that keep up with the times.

Switch on the power of sustainable innovation

Even the most high-tech applications must respect the basic needs of the planet to be truly advanced. Our Exolit™ range can provide fire resistance to thin and printed electronics, while preserving the properties of electrical parts and resisting challenging conditions. At the same time, it brings a new kind of safety and sustainability to thermoplastics and thermosets.

All our flame retardants are halogen-free, based on powerful yet safe phosphorus chemistry and produced with 100% green electricity. With our earth-friendly Exolit™ OP Terra range, we also offer solutions with equal high performance and renewable carbon origin.

Find out more about our solutions for the E&E industry

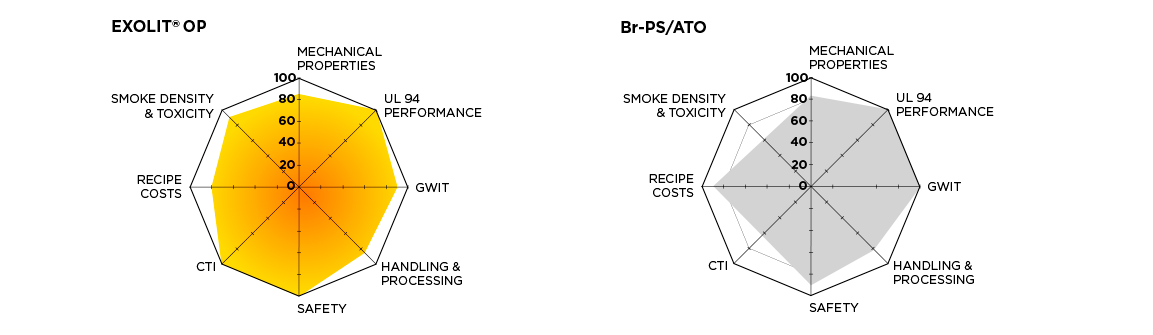

Technically and economically competitive with EXOLIT™ OP flame retardants in polyamides

High standards for the new standard benefits of our solutions for E&E

1.Compounds made with Exolit™ OP combine good mechanical properties with high Comparative Tracking Index (CTI, a measure for the tendency to short-circuit) values

2.Exolit™ OP products can be applied in 5G materials, including high-frequency and high-speed printed circuit boards (PCBs)

3.Good colorability of compounds made with Exolit™ OP allows branding of electrical and electronic parts

How can we make halogen-free flame retardants even more sustainable? Angelika Schmidt has the answer

»The Exolit™ OP series provided us with a halogen-free flame retardant that doesn’t compromise on performance. The OP Terra range makes these products even more sustainable and is a perfect fit for our planned portfolio of solutions with enhanced recycled or bio-based content.«

Dr. Angelika Schmidt

Research &Technology Manager, DSM Engineering Materials

E&E fire protection with the numbers

VHighest class

for Comparative Tracking Index

(CTI) of insulating materials

mmLowest thickness

at which UL 94 V-o can be

achieved with

Exolit™ OP

≤D95 particle size

makes Exolit™ OP suited

for very thin adhesive

applications