Our solutions for fabric bonding -

high-performing fabric adhesives

with a planet-friendly weave

Enhanced hot melt laminating and coating in mattress making and other fields

Hot melt adhesives are used in many fabric bonding applications and have become the joining solution of choice in mattress manufacturing. Here these clean and easy-to-handle fabric adhesives are employed for hot melt coating, hot melt laminating, as well as other parts of mattress assembly.

Our Licocene™ offerings outperform standard EVA adhesives not just in terms of bonding strength and thermal stability but also in the highly consumer-relevant category of odor. With our Licocene™ Terra products, we offer earth-friendly versions of our polymers and waxes that are based on renewable C2/C3 starting materials and combine their excellent bonding properties with a substantially reduced carbon footprint.

Watch how we innovate to improve fabric bonding

By enhancing the renewability of mattress adhesives and the recyclability of car carpets, our Licocene™ solutions take sustainable bonding innovation to the next level.

Easy-to-process, low-odor polymer adhesives that put consumer mind’s at rest

Our Licocene™ solutions can be used to coat, laminate and join fabrics as 100% polymer-based stand-alone adhesives or as part of hot melt formulations. They are suited for slot-die coating, roller coating and spray application and ensure fast and easy bonding that doesn’t glue down your production times.

Low odor and low emission of volatile organic compounds (VOCs) add to the excellent mix of properties that make Licocene™ products the number one choice for applications like mattress ticking and pocket springs. The reduced carbon footprint that can be achieved by using our renewably derived Licocene™ Terra solutions comes with no compromise in terms of any performance parameters.

Find out more about our solutions for fabric applications

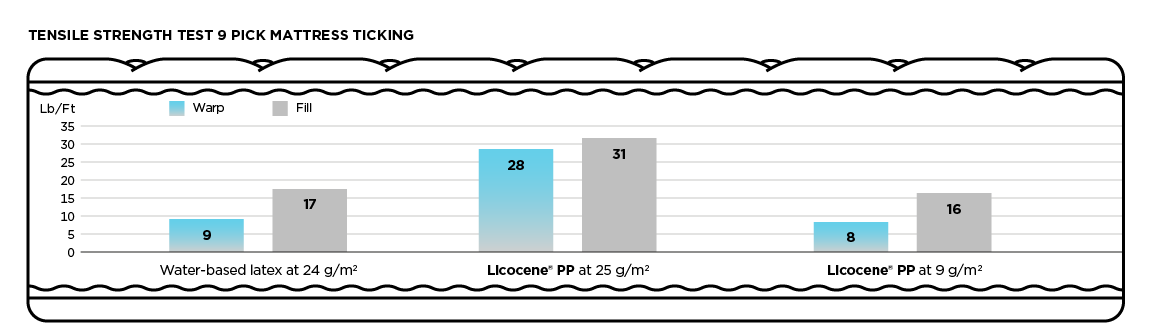

Improvements in strength that mattress makers dream of

Three good reasons for choosing Clariant

key benefits of our Licocene™ solutions

1.Less weight added by our products results in lighter fabrics and products

2.Reduced odor and VOCs help address key consumer concerns about furniture and fabrics

3.Absent residual tack and dry hand give an authentic feel to coated ticking and other textile substrates

Performance and purity you can count on

up to %Less weight

added onto the weight

of fabrics and products

%Flexibility in feel

covering the whole range from

a soft to stiff fabric hand

%Polymer adhesives

without harmful additions that

consumers can lose sleep over