Styrene Production

Maximum Performance with StyroMax Catalysts

Optimize the productivity and performance of your styrene monomer production plant with Clariant – a leading, independent global catalyst supplier with over 70 years of experience in styrene catalysis.

We combine a matchless portfolio of high-performance StyroMax™ dehydrogenation catalysts with expert technical support to deliver innovative solutions that meet your exact needs. Discover how we can help you reach your targets – reliably, economically, and sustainably.

For even greater reliability, all our StyroMax Catalysts are also available in our exclusive rib shape, designed to drastically lower pressure drop.

PODCAST

Breaking Barriers in Styrene Production

with StyroMax UL-100

Hydrocarbon Processing

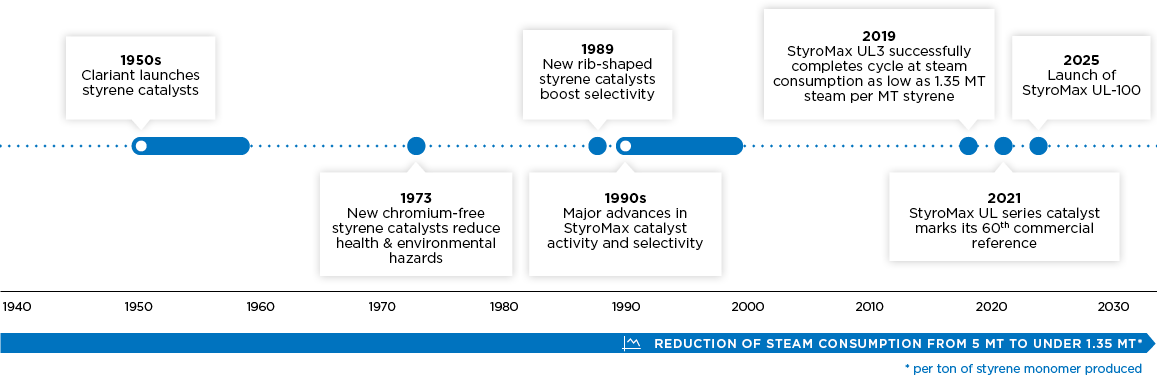

70 years of steam reduction

Why use Clariant styrene catalysts?

EXTENSIVE EXPERIENCE

> 1000

production cyclesusing Clariant styrene catalyst over 70 years

EXPERT SUPPORT

11

regional engineering officeslocated close to our customers

HIGH SATISFACTION

> 90%

repeat customers of StyroMaxdue to excellent selectivity and activity

Solutions that drive performance

Styrene Catalysts

Customer events

Join our seminars, webinars, and workshops to learn about the latest trends and most innovative styrene solutions

Applied Catalyst Technology

CLARITY™ Prime

Let our experts help you with our AI-digital powered service to increase production rates, increase yields, extend cycle length, and reduce steam and energy consumption

Styrene Catalysts

StyroMax rib-shaped catalysts

Discover how our exclusive rib shape minimizes pressure drop to maximize productivity in styrene production

Styrene Catalysts

StyroMax catalyst portfolio

Select the right StyroMax catalyst from our broad portfolio to boost your styrene unit's profitability

News

Any Questions?

CONTACT US