StyroMax rib-shaped catalysts

PODCAST

Less Steam, more Styrene:

The benefit of ribbed shaped catalysts

for ethylbenzene dehydrogenation.

Hydrocarbon Processing

Reactor pressure is critical in styrene production, as elevated pressures increase by-product formation. Extreme pressures may also impact the performance of the evaporating systems.

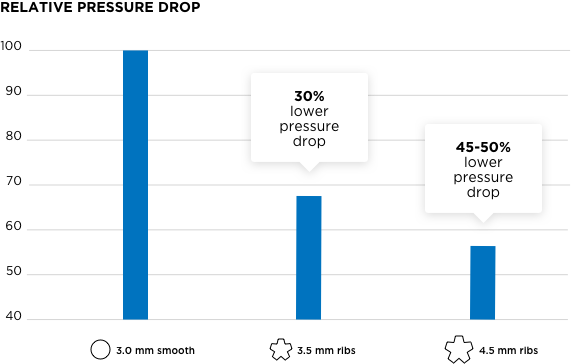

The solution: Clariant's StyroMax rib-shaped catalysts’ unique design reduces pressure drop by 30 to 50% compared to standard cylindrical shapes at similar operating conditions.

Going with the flow

StyroMax rib-shaped catalysts have a cylindrical core supported by five ribs that create five channels and strengthen the catalyst pellet. The unique geometry prevents the ribs from fitting into the channels.

The higher void fraction of the rib extrusions lowers pressure resistance during operation.

The channels improve flow distribution, enabling more uniform profiles in the reactor.

Reduced overall pressures greatly benefit the thermodynamics of ethylbenzene dehydrogenation.

The shape’s high surface area increases catalyst activity, since the reaction rate is mass-transfer controlled.

Lower pressure drop

Proven technology, in commercial operation for more than 30 years

Excellent flow distribution throughout loaded beds

Higher activity due to greater catalyst surface area

Less by-product formation due to favorable pressure conditions

Improved performance, stability, and tolerance to operational upsets

Available for all StyroMax series catalysts

Unique performance benefits

ROBUST CATALYST

> 25%

higher mechanical strengthprotects catalyst during loadingand operation

ADDITIONAL PROTECTION

> 15%

lower loaded weightreduces mechanical stress in reactorand prevents screen damage

SMOOTH OPERATION

> 50%

lower pressure dropduring full cycle favors dehydrogenationand prevents by-products