MegaZonE™

Novel catalyst-layering technology for enhanced methanol synthesis

Clariant’s efforts to continuously improve methanol catalyst performance are not limited solely to catalyst formulation, but also focus on the overall process and how the catalysts can be optimally utilized in the complete reactor system.

The result is a major breakthrough in methanol synthesis: MegaZonE™ technology. Based on Clariant’s MegaMax™ catalyst series, and jointly developed with Air Liquide E&C, the innovative method uses several layers of catalysts with different activity levels to optimize heat management and overall catalyst performance in the methanol synthesis reactor. With MegaZonE technology, the properties of each catalyst layer are tailored to the specific conditions along the reaction pathway, resulting in longer lifetimes of the catalysts, and higher methanol yields for our customers.

Product Benefits

Less thermal stress

due to mild operation condition

Increased catalysts lifetime

of 12-18 months due to less thermal stress

Low by-product formation thermal stress

up to 10% higher selectivity

Customer Benefits

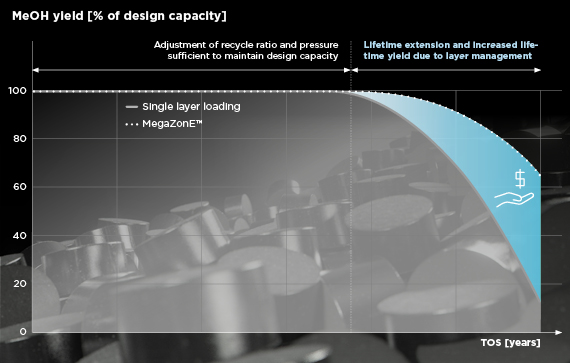

INCREASED CUMULATIVE METHANOL PRODUCTION

up to 10%-15%

SIGNIFICANT MONETARY BENEFITS

for methanol producers

MORE COMPACT PLANT DESIGN WITH SAME CAPACITY

and feed gas flexibility

ENERGY SAVINGS

improved energy efficiency of 0.15%

How MegaZonE works

To optimize the process conditions of the methanol synthesis reaction, several layers of catalysts with different activity levels are arranged in the tubular reactor. Different activity levels are achieved by distinctive catalyst generations or shapes:

- MegaMax catalysts with lower activity in top portion of reactor to avoid hotspots

- MegaMax catalysts with higher activity in the middle and bottom of the reactor to intensify reactions

Increased production rate and catalyst lifetime

The unique MegaZonE layer arrangement reduces the thermal stress on catalysts on the catalysts at the main reaction front, leading to an optimized use of the highly active catalyst in the top part of the reactor and of the reaction rate in the bottom part. The flattened temperature profile and the improved overall performance result in extended catalyst lifetime and increased methanol yield over the lifetime.