Rice bran wax additives Licocare™ RBW

Vita function as lubricants, dispersants,

and nucleators for engineering plastics

Moving towards greater performance and sustainability

Plastics are substituting traditional – i.e. metallic – materials, and thus need high temperature additives for the demanding under-the-hood, electrical and high-temperature polymer packaging applications. Rice bran wax is a natural and sustainable alternative to other waxes, including montan and synthetic waxes, providing customers with options to meet their supply and sustainability needs while maintaining the desired product characteristics. Clariant’s innovative, bio-based range of additives, Licocare RBW Vita, supports this development and delivers on both performance and sustainability. The Licocare RBW Vita range offers a remarkable reduction of up to 70% in product carbon footprint (PCF) compared to traditional fossil-based montan waxes, providing an alternative with a significantly lower environmental impact.

Based on renewable rice bran wax, a non-food competing by-product of the rice bran oil production, Licocare RBW Vita additives act as effective lubricants, dispersion agents and nucleating agents. The main target applications are engineering thermoplastics such as polyamides, polyesters, polyurethanes, epoxy resins and biopolymers like PLA. Rice bran waxes increase the flow of polyesters, e.g. PET, while improving roller and metal release, to allow faster production rates of clear and translucent PET for both food (FDA approved) and security packaging. They are also excellent organic pigment dispersants.

Licocare RBW Vita products have obtained various food contact approvals:

- FDA approved for use in polyesters (PET, PBT, PETG, co-polyesters)

- FDA approved for bio-based polymers (PLA, PHA)

- FDA approved for TPU, rubber, and rigid PVC in repeated-use food processing equipment

- EFSA approved for PET, PLA, Rigid PVC

- Japan food safety positive list for use in all polymers

Please contact your Clariant representative for detailed information.

These rice bran wax solutions carry the Vita designator indicating that they are based on renewable feedstock with at least 98% RCI, Renewable Carbon Index. Customers seeking natural or plant-based alternatives will value these rice bran waxes for their reduced carbon footprint compared to montan waxes, which also contributes to a lower overall carbon footprint of the final product when using rice bran wax.

Benefits of our Licocare™ rice bran waxes

The Licocare™ RBW Vita portfolio offers various valuable features and benefits to plastics compounders and masterbatch producers to fulfill demanding requirements set by industries such as transportation and electrical & electronics producers. Our high performing waxes improve melt flow, ease mold release force and ensure a more homogeneous distribution of pigments. The bio-based additive solutions also have an excellent environmental profile which is conducive to achieving corporate sustainability targets.

Clariant has earned a Gold level Material Health Certificate for Licocare™ RBW Vita, which is awarded to products that meet the Material Health requirements of the multi-attribute Cradle to Cradle Certified™ Product Standard. Furthermore, the Licocare™ RBW Vita range has also been awarded the “OK compost INDUSTRIAL” certificate from TÜV Austria Cert GmbH. Also, the Licocare™ RBW 102 Vita was awarded the “OK biodegradable SOIL” label. Herewith, Clariant contributes to the development of industrially compostable plastics as well as biodegradable coatings for agriculture.

Sustainability performance

- No hazard labels

- Based on renewable resources with real renewable content of at least 98% RCI (Renewable Carbon Index)

- Contributes to efficiency and energy saving in production

- Up to 70% product carbon footprint (PCF) reduction compared to traditional fossil-based montan waxes

- Made from non-food competing by-product of rice bran oil production, improving the rice value chain

Key product features

- Improved melt flow

- Lower mold release force

- High temperature stability

- Low volatility and migration

- Effective dispersion of fillers & pigments

- Better color and appearance (lighter) compared to legacy products

Your benefits

- Improved shaping flexibility

- Reduced rejection rates

- Better mechanical properties

- Smooth surfaces

- Increased productivity through shorter cycle times

- Constant output and controlled unit costs

- Contributes to achieving your corporate sustainability targets

Renewable, non-food-competing feedstock

Outstanding performance

Consistent manufacturing

Multi-functional

Find the right rice bran wax for your polymer and application

- Make molded parts more rapidly with Licocare RBW 300 Vita for faster flow and mold release.

- If needing to nucleate PA for faster cycles in injection molding, Licocare RBW 330 Vita or Licocare RBW 360 Vita work great.

- Difficult geometries may be filled via a faster flow and less drag, while providing excellent release with Licocare RBW 101 Vita and Licocare RBW 102 Vita.

- Maximize organic pigment dispersion with Ceridust 1060 Vita and Ceridust 1041 Vita.

- If nucleation of PET/PBT is needed for faster cycles in injection molding, Licocare RBW 560 Vita TP is the product of choice.

- Maximize organic pigment dispersion with Ceridust 1060 Vita.

A faster process, while reducing roller and mold sticking may be achieved with Licocare RBW 102 Vita.

Gloss improvements in highly-filled PP molded parts can be seen with Licocare RBW 300 Vita.

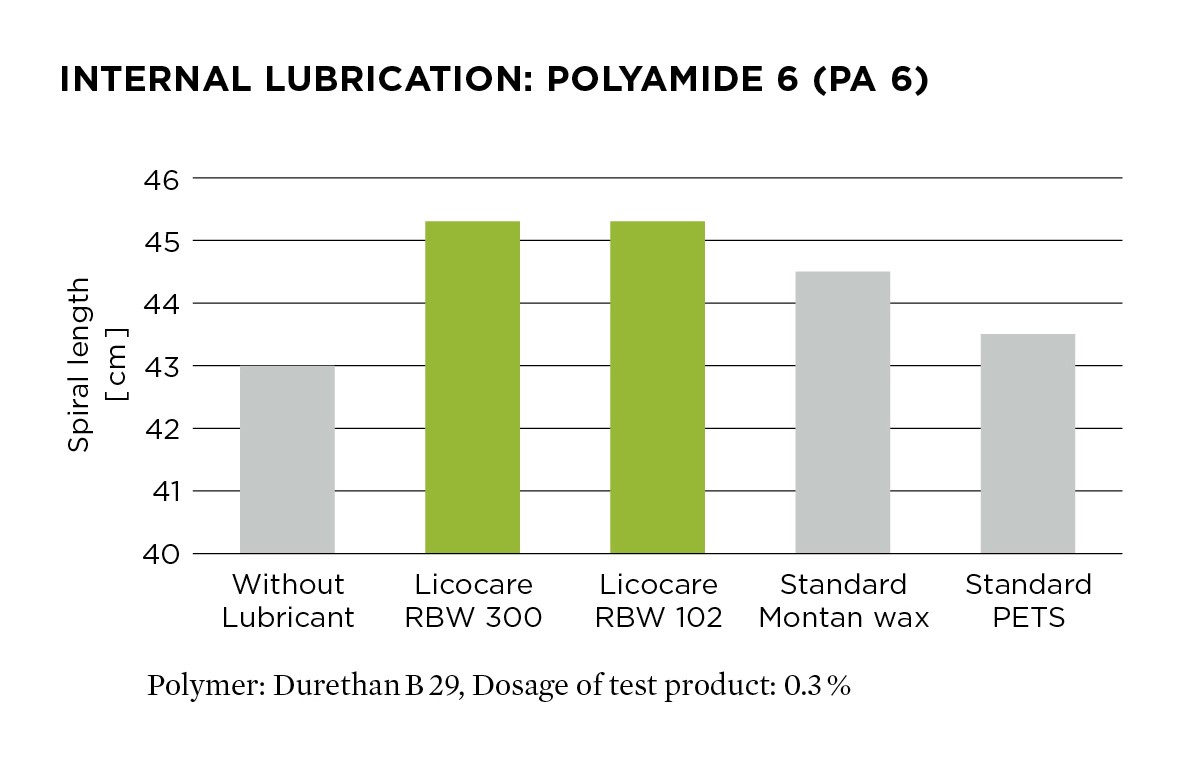

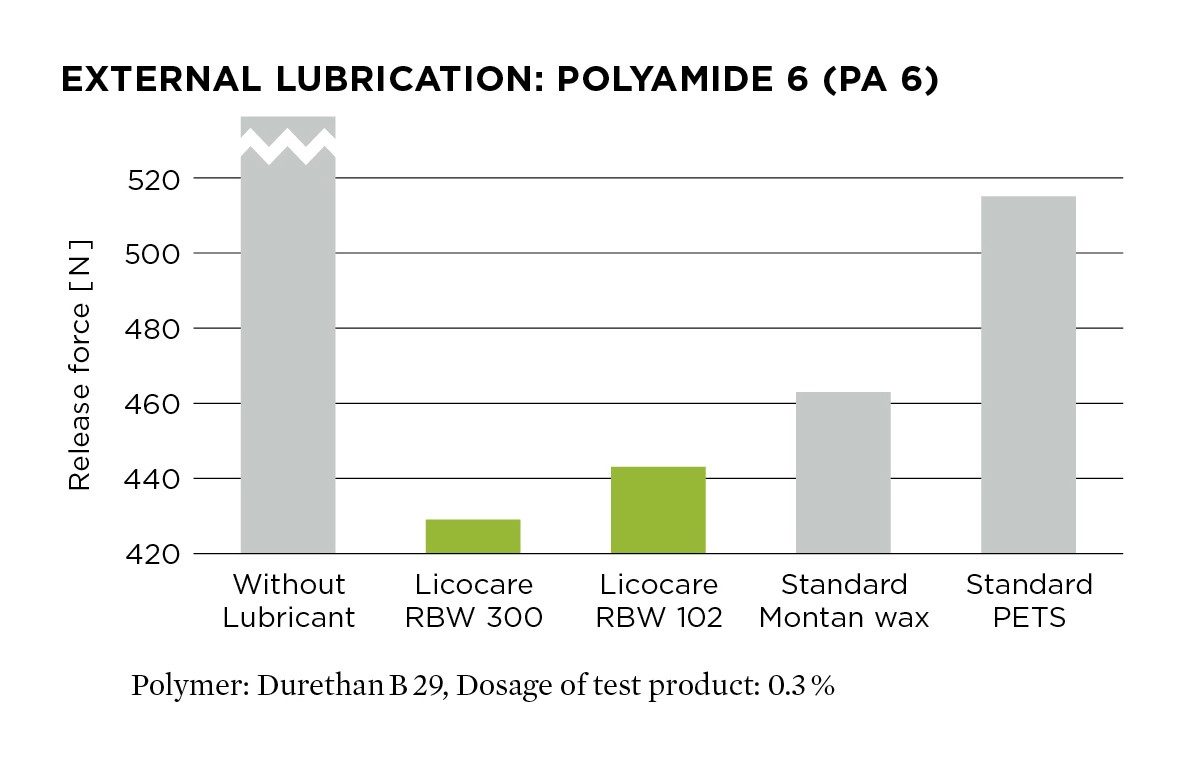

Internal and external lubrication can be achieved with Licocare RBW 102 Vita and Licocare RBW 300 Vita.

Improved material flow and excellent release is provided with Licocare RBW 102 Vita.

Application tests by Clariant show that Licocare™ RBW Vita solutions achieve higher performance levels compared to alternative solutions on the market. Application data for other polymer types also available.

From rice grain to Licocare™ RBW Vita

Our multi-purpose additives are derived from crude rice bran wax. This is a by-product from the production of rice bran oil. Clariant chemically and physically upgrades this renewable raw material and thus contributes to using the rice grain's full value. With biobased solutions like our Licocare™ RBW Vita additives, we take the sustainable enhancement of plastics to the next level. Watch how we innovate to improve plastics.