Discover sustainable additives.

What it takes to build a safe home

Protecting the protectors

As a species, we humans seek protection—building areas of sanctuary, constructing interiors to shield from the exterior. The roof above our heads has become symbolic for protecting both our family and valuables. Our house protects us—but what protects our house?

From the pit house to the smart home

When we think of a house, visions of comfort and familial sanctuary come to mind. Yet, the house has seen many shapes and forms in its evolution—each adding to the functionality, comfort and aesthetics of our homes. But to truly know what we’ve got, we have to start at the beginning.

Invisible heroes saving lives

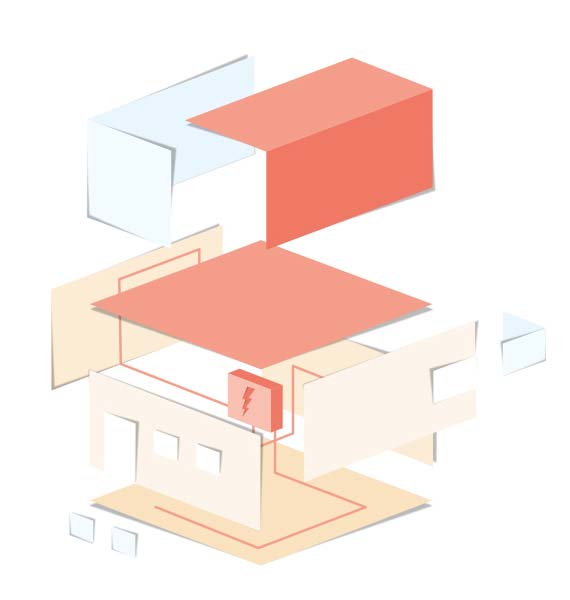

Sometimes a tiny helper can make a massive difference and save lives. Take flame retardants, for example. They are found throughout the house wherever fire would cause significant damage to the housing structure—from fuse boxes in the cellar to carpets, upholstery and electronic devices in the living room, all the way up to insulation in the attic. Especially vulnerable is a house’s electrical system—over 30% of all house fires are caused by short circuits. By using our Exolit™ products in potential ignition sources, like electrical systems and electronics, this risk can be reduced considerably.

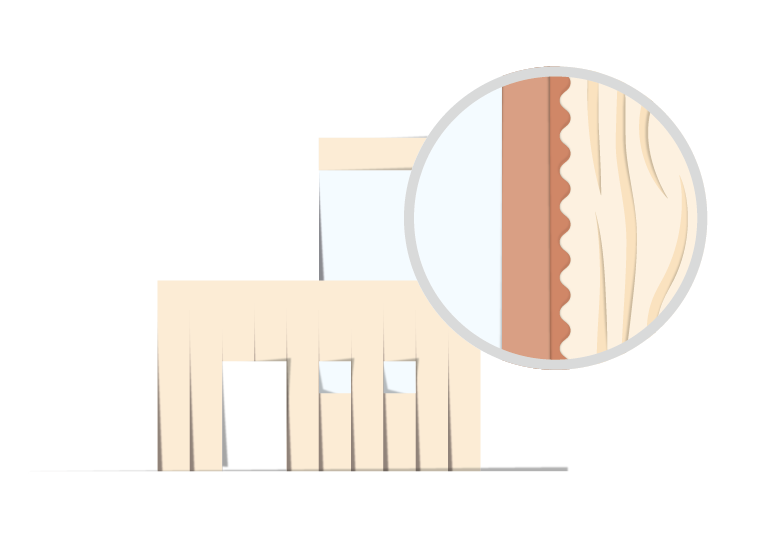

Not only is Clariant the pioneer for non-halogenated flame retardants with excellent environmental profiles, but we are constantly striving to expand its portfolio. AddWorks™ LXR 920, for example, is a new synergistic non-halogenated flame retardant solution for films and sheets which is applied in housing roofing sheets.

Learn where and how flame retardants act

How many lives can be saved in just a few more minutes?

Do non-halogenated flame retardants do their job? Wolfgang Diegritz has the insights

Have you ever experienced fire personally?

Fortunately, I have never personally experienced a fire break-out. As a child, I remember seeing how the roof structure of a house had caught fire. It was an impressive event for me, watching the immense power, speed and size of the flames, which firemen took long and strong efforts to extinguish.

»Halogen-free flame retardants have been developed to lower the smoke toxicity and to prevent the migration of the additives..«

What are the most common causes of fire?

In newspapers and other media, we surprisingly often read reports about fire accidents and combustion processes. From my perspective the main reasons for the break-out of fires are technical defects in electrical and electronic devices (e.g., short circuits) or industrial devices (e.g., malfunction of machinery) as well as human failure and inadvertence (e.g., burning candles).

How do flame retardants reduce the impact of fires on people, property and the environment?

In an early stage of the ignition process, flame retardants can substantially contribute to extinguishing a smoldering fire (e.g., overheated electric device). At a later stage of fire—or when the fire is spreading too strong or too fast-the flame retardants cannot stop the flashover of a fire anymore. However, they can limit the impact and damage (e.g., flame retardant curtains not catching fire rapidly). And, providing a very important benefit, they can save human lives by increasing the time available for people to escape the fire (e.g., flame retardant-equipped plastics in public transportation).

What are the advantages of halogen-free flame retardants over halogenated alternatives?

Conventional halogenated flame retardants do their job. It’s clear. But the “Achilles heel” of these chemicals are their toxicity and their side effects: On the one hand some of these additives are listed as Substances of Very High Concern (SVHC). On the other hand a fire can release many toxic substances from halogenated flame retardants, like brominated dioxins and furans. In addition, halogenated flame retardants are commonly used together with antimony trioxide. Halogen-free flame retardants have been developed to lower the smoke toxicity and to prevent the migration of the additives. Furthermore, there is no compromise in flame retardancy and little impact on technical parameters of the final application. In the meantime, rethinking leads to a significant variety of halogen-free flame retardants, most often tailor-made for individual polymers and applications

Dr. Wolfgang Diegritz,

Senior Engineer Field Development – E&E, Europe, Celanese

AddWorks™: Numerous requirements - one solution

- Our products are used in a variety of industries. Furthermore, a single additive has to fulfill several requirements depending on the function, area of application or polymer type. With AddWorks™ we cluster together the wide range of applications in a single solution.

- Customers no longer have to resort to several products with various functions, but rather receive the total range of functionality for a given area of application in one solution. The AddWorks™ palette ranges from solutions in the fields automotive and transportation to agriculture, textile fiber and packaging.

- Our customers benefit from the tailor-made AddWorks™ formulations for all areas of polymer processing. They boost productivity, increase the stability and durability of manufactured parts, while additionally protecting them in the manufacturing process and generating significant energy savings.

Discover more about AddWorks™

AddWorks™ LXR 920: A new non-halogeneted flame retardant for films & sheets

AddWorks™ LXR 920 is a synergistic non-halogenated flame retardant solution for house roofing sheets, such as vapor retarders used in attic insulation. Such roofing sheets containing AddWorks™ LXR 920 not only fulfill European (Flammability Class E, EN 13501-1) and American (NFPA 701) fire protection standards, but also boast several additional benefits:

- No odor & no fumes during the processing of the sheets

- Thermal stability

- Good UV protection

- High chemical resistance

- Good compatibility

- Good pigment distribution

Protecting the wood from the wall to the table

When wood is stripped of its bark, it is bare and unprotected—completely vulnerable to wind and weather. This sensitive material requires special protection both inside and out. Only then can wood provide the comfort and warmth for those who desire it.

How did the invention of Licocene come about?

Was it serendipitous or market-driven?

Initially, Clariant recognized the importance of polyolefins made by metallocene catalysts and started to invest heavily in this new technology. That Licocene developed in such a successful way is due to its unique properties: high-performing and sustainable additives for adhesives and beyond. This complete toolbox convinces a daily increasing number of customers. Based on a strong market-driven approach, we continue to further enhance our solutions and products, offering to fulfill the unmet needs of our customers.

»We started to invest heavily in polyolefins made by metallocene catalysts.«

Why is manufacturing components and furnishings with flat lamination gaining in importance? What makes it more sustainable?

Licocene has made its way into the entire range of applications in the world of adhesives. Besides assembly, paper, transportation and footwear, we are also covering wood-working adhesives for edge-banding or profile-wrapping. We make the same promise for every application: Gain better bonding with less adhesive. Flat lamination will become a vivid part of this. Here we target the market entry with an entirely new water-curing adhesive which offers unique differentiation from alternative solutions with regard to health and safety questions. Licocene benefits both the planet and our customers’ production: It saves water, has a lower carbon footprint, needs less energy and performs better. In recognition of this and based on comparison with the other available solutions, we have received the EcoTain™ sustainability certification for our key products.

How does Licocene differ from comparable products?

To achieve superior bonding you have to provide adhesion and cohesion to the joint. The balance between both makes the difference. We are offering both: unique cohesive power and premium adhesive strength. Besides that, factors such as low density, low viscosity and excellent thermal stability maximize the overall benefit in the bonding and manufacturing process. Our key success formula is easy:

- Utilize the Licocene formulation approach to achieve high-polymer-content adhesives.

- Realize high-performance bonding with less application weight and cut down manufacturing costs as a result.

»We make the same promise for every application: Gain better bonding with less adhesive.«

Flat lamination

Thanks to an innovative metallocene catalyst, Licocene™ can adjust its adhesive function to meet any given requirement—from window sealants to veneered furniture.

It all ads up: the benefits at a glance

Renewable raw material

Ceridust™ 8090 and 8091 for interior wood coatings provides a natural haptic and is based entirely on renewable raw materials that do not compete with food.

Fire safety

We offer long-term, reliable products that pass demanding fire safety standards and minimize secondary fire damages.

Non-halogenated technology

Clariant is the pioneer in non-halogenated technologies. With this exclusive know-how, we’ve developed a broad portfolio of products for a variety of uses, from thick to thin-walled applications.

UV Protection

Hostavin™ 3330 Disp. and Hostavin™ 3070 Disp. are additives for exterior water-based wood coatings with excellent UV stabilization performances.

Environment

Our portfolio consists of highly efficient, non-halogenated flame retardants with preferable environmental profiles.

Easy to use

Licocene™ adhesives, used for wooden flat lamination and free of solvent and urea, is an easy-to-use toolbox with individually adaptable adhesion, cohesion and melting point properties.